Innovations in Data Center Power and Cooling Solutions

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

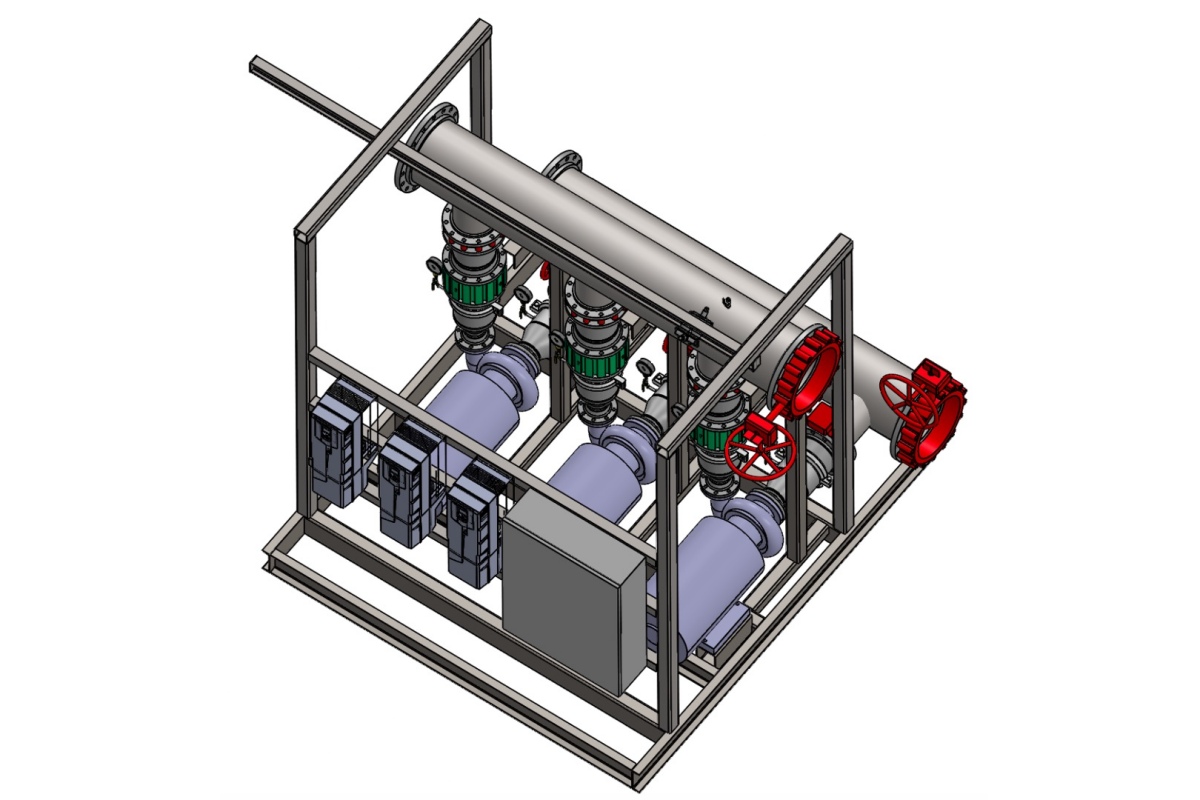

Aggreko expands liquid-cooled load banks for AI DCs

Aggreko, a British multinational temporary power generation and temperature control company, has expanded its liquid-cooled load bank fleet by 120MW to meet rising global demand for commissioning equipment used in high-density data centres.

The company plans to double this capacity in 2026, supporting deployments across North America, Europe, and Asia, as operators transition to liquid cooling to manage the growth of AI and high-performance computing.

Increasing rack densities, now reaching between 300kW and 500kW in some environments, have pushed conventional air-cooling systems to their limits. Liquid cooling is becoming the standard approach, offering far greater heat removal efficiency and significantly lower power consumption.

As these systems mature, accurate simulation of thermal and electrical loads has become essential during commissioning to minimise downtime and protect equipment.

The expanded fleet enables Aggreko to provide contractors and commissioning teams with equipment capable of testing both primary and secondary cooling loops, including chiller lines and coolant distribution units. The load banks also simulate electrical demand during integrated systems testing.

Billy Durie, Global Sector Head – Data Centres at Aggreko, says, “The data centre market is growing fast, and with that speed comes the need to adopt energy efficient cooling systems. With this comes challenges that demand innovative testing solutions.

“Our multi-million-pound investment in liquid-cooled load banks enables our partners - including those investing in hyperscale data centre delivery - to commission their facilities faster, reduce risks, and achieve ambitious energy efficiency goals.”

Supporting commissioning and sustainability targets

Liquid-cooled load banks replicate the heat output of IT hardware, enabling operators to validate cooling performance before systems go live. This approach can improve Power Usage Effectiveness and Water Usage Effectiveness while reducing the likelihood of early operational issues.

Manufactured with corrosion-resistant materials and advanced control features, the equipment is designed for use in environments where reliability is critical.

Remote operation capabilities and simplified installation procedures are also intended to reduce commissioning timelines.

With global data centre power demand projected to rise significantly by 2030, driven by AI and high-performance computing, the ability to validate cooling systems efficiently is increasingly important.

Aggreko says it also provides commissioning support as part of project delivery, working with data centre teams to develop testing programmes suited to each site.

Billy continues, “Our teams work closely with our customers to understand their infrastructure, challenges, and goals, developing tailored testing solutions that scale with each project’s complexity.

"We’re always learning from projects, refining our design and delivery to respond to emerging market needs such as system cleanliness, water quality management, and bespoke, end-to-end project support.”

Aggreko states that the latest investment strengthens its ability to support high-density data centre construction and aligns with wider moves towards more efficient and sustainable operations.

Billy adds, “The volume of data centre delivery required is unprecedented. By expanding our liquid-cooled load bank fleet, we’re scaling to meet immediate market demand and to help our customers deliver their data centres on time.

"This is about providing the right tools to enable innovation and growth in an era defined by AI.”

For more from Aggreko, click here.

Joe Peck - 5 December 2025

Data Centre Infrastructure News & Trends

Enterprise Network Infrastructure: Design, Performance & Security

Innovations in Data Center Power and Cooling Solutions

Vertiv launches DC power system for networks in EMEA

Vertiv, a global provider of critical digital infrastructure, has introduced the Vertiv PowerDirect 7100 Energy, a hybrid-ready DC power platform designed to support next-generation telecom and edge networks across Europe, the Middle East, and Africa (EMEA).

The system is engineered to strengthen power stability in environments ranging from robust grid connections to remote or off-grid locations while supporting operators’ wider energy transition strategies.

The PowerDirect 7100 Energy provides up to 52 kW of scalable 48 V DC power and reportedly achieves efficiencies of up to 98%.

Built on Vertiv’s fourth-generation hybrid architecture, it can integrate inputs from grid, generators, and alternative energy sources including solar, wind, or fuel-cell systems.

Intelligent power management for diverse deployments

At the core of the platform are Vertiv solar converters and modular rectifiers, managed by the Vertiv NetSure Control Unit.

This combination enables remote monitoring, advanced load control, and energy scheduling to optimise system performance and extend equipment lifespan.

Dave Wilson, Director of Global Hybrid Solutions at Vertiv, comments, “The world expects energy efficiency and flexibility with the growth of communications such as 5G and edge connectivity.

"The Vertiv PowerDirect 7100 Energy gives operators a single, intelligent platform capable of adapting to any grid condition, delivering reliable power while supporting the transition to cleaner, more efficient energy strategies.”

Built for harsh and space-constrained sites

The system is available in 500 A, 750 A, and 1000 A configurations for telecom and edge data racks.

A front-access layout simplifies installation and servicing, while an operating range of –40°C to +65°C allows for deployment in challenging or remote locations.

The PowerDirect 7100 Energy joins Vertiv’s wider portfolio of Vertiv NetSure systems and hybrid-energy platforms within the company’s power-train architecture.

Paired with Vertiv thermal management, IT management, and lifecycle support services, it seeks to provide operators with a foundation for resilient and efficient digital infrastructure.

For more from Vertiv, click here.

Joe Peck - 25 November 2025

Data Centre Build News & Insights

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Renewables and Energy: Infrastructure Builds Driving Sustainable Power

Terra Innovatum, Uvation agree micro-modular nuclear pilot

Terra Innovatum Global, a developer of micro-modular nuclear reactors, and Uvation, an integrated technology provider, have signed a Letter of Intent (LOI) to launch a 1MWe pilot programme of Terra Innovatum’s micro-modular nuclear technology, with an option to scale up to 100MWe.

The pilot is intended to support Uvation’s growing requirements for high-density AI and modular data centre infrastructure.

Terra Innovatum develops micro-modular nuclear reactors, while Uvation focuses on technology platforms designed for large-scale, performance-intensive AI workloads.

The companies state that behind-the-meter nuclear generation could provide a resilient and scalable alternative to grid-dependent power for data centre development.

Alessandro Petruzzi, co-founder and CEO at Terra Innovatum, comments, “Uvation’s data centre expansion requires infrastructure that is not only scalable, but fundamentally resilient.

"By integrating Terra Innovatum’s SOLO micro-modular reactor, we will offer a behind-the-meter energy source capable of delivering safe, stable, high-density power that traditional grids cannot guarantee.

"SOLO adds built-in safety and provides redundancy - important for data centres, de-risking energy deployment during maintenance or shutdowns, ensuring continuity independent of power shortages, and enhancing cybersecurity protection.

"This enables next-generation, high-performance modular data centres powered by a clean, uninterrupted energy backbone - unlocking new possibilities for AI, HPC, and mission-critical workloads.”

Nuclear as an alternative pathway for energy-constrained AI projects

Giordano Morichi, Founding Partner, Chief Business Development Officer and Investor Relations, adds, “As AI infrastructure outpaces today’s grid, the constraint is no longer processing power; it’s reliable, cost-effective power. Uvation’s future commitment to behind-the-meter nuclear reflects a broader market reality: energy security now defines the speed at which AI can scale.

"SOLO fast-tracks AI commercialisation by providing near-instant, CO₂-free, revenue-generating power while sidestepping the delays and CapEx overruns inherent to traditional grid-dependent solutions.

"This agreement also strengthens our commercial deployment and positions nuclear as the most viable path to support Uvation’s planned multi-gigawatt growth in the AI and data centre sector.”

Reen Singh, CEO of Uvation, notes, “Global demand for AI, driven by the US, and the need for sovereign cloud infrastructure is accelerating far faster than the available power to support it. Some of our off-takers forecast demand exceeding 1GW, yet current infrastructure and lack of readily available access to energy limit the scale of deployments.

“Power shortages have been major forces in this industry’s project delays. By integrating Terra Innovatum’s SOLO reactor into our future roadmap, we will look to secure immediate power along with a reliable, behind-the-meter energy source that enables scalable AI, inference, and edge deployments.

"Our future 1MWe SOLO pilot program represents a critical first step, with a path to expand to 100 MWe across multiple sites and potentially several megawatt-scale installations throughout the US.”

The companies intend the pilot to act as a foundation for potential multi-site expansion, citing accelerating power demand and increasing constraints on conventional grid-connected data centre projects.

Joe Peck - 21 November 2025

Data Centre Infrastructure News & Trends

Data Centre Security: Protecting Infrastructure from Physical and Cyber Threats

Innovations in Data Center Power and Cooling Solutions

Products

Security Risk Management for Data Centre Infrastructure

SPP Pumps brings fire and cooling experience to DCs

SPP Pumps, a manufacturer of centrifugal pumps and systems, and its subsidiary, SyncroFlo, have combined their fire protection and cooling capabilities to support the expanding data centre sector.

The companies aim to offer an integrated approach to pumping, fire suppression, and liquid cooling as operators and contractors face rising demand for large-scale, high-density facilities.

The combined portfolio draws on SPP’s nearly 150 years of engineering experience and SyncroFlo’s long history in pre-packaged pump system manufacturing.

With modern co-location and hyperscale facilities requiring hundreds of pumps on a single site, the companies state that the joint approach is intended to streamline procurement and project coordination for contractors, consultants, developers, and OEMs.

SPP’s offering spans pump equipment for liquid-cooled systems, cooling towers, chillers, CRAC and CRAH systems, water treatment, transformer cooling, heat recovery, and fire suppression. Its fire pump equipment is currently deployed across regulated markets, with SPP and SyncroFlo packages available to meet NFPA 20 requirements.

Integrated pump systems for construction efficiency

The company says its portfolio also includes pre-packaged pump systems that are modular and tailored to each project. These factory-tested units are designed to reduce installation time and simplify on-site coordination, helping to address construction schedules and cost pressures.

Tom Salmon, Group Business Development Manager for Data Centres at SPP and SyncroFlo, comments, “Both organisations have established strong credentials independently, with over 75 data centre projects delivered for the world’s largest operators.

"We’re now combining our group’s extensive fire suppression, HVAC, and cooling capabilities. By bringing together our complementary capabilities from SPP, SyncroFlo, and other companies in our group, we can now offer comprehensive solutions that cover an entire data centre's pumping requirements.”

John Santi, Vice President of Commercial Sales at SyncroFlo, adds, “Design consultants and contractors tell us lead time is critical. They cannot afford schedule delays. Our pre-packaged systems are factory-tested and ready for immediate commissioning.

"With our project delivery experience and expertise across fire suppression, cooling, and heat transfer combined under one roof, we eliminate the coordination headaches of managing multiple suppliers across different disciplines.”

Tom continues, “In many growth markets, data centres are now classified as critical national infrastructure, and rightly so. These facilities cannot afford downtime, and our experience with critical infrastructure positions us to best serve this market."

Joe Peck - 20 November 2025

Data Centre Build News & Insights

Data Centre Infrastructure News & Trends

Data Centre Projects: Infrastructure Builds, Innovations & Updates

Innovations in Data Center Power and Cooling Solutions

NorthC, Legrand upgrade Münchenstein (Basel) data centre

NorthC Data Centers, a Dutch provider of sustainable data centre and colocation services, has partnered with Legrand, a French multinational manufacturer of electrical and digital building infrastructure products, to upgrade its Münchenstein (Basel) site, introducing higher-density infrastructure to support AI, hybrid-cloud, and high-performance computing workloads.

The project was completed within a six-month window to meet rising regional demand for GPU-driven environments.

NorthC operates regional facilities across Switzerland, the Netherlands, and Germany. The company sought to replace low-density systems and traditional air-cooling at the Münchenstein site to accommodate higher power and thermal loads associated with modern AI deployments.

Legrand, through USystems, supplied rear-door heat exchangers for rack-level cooling. These units are mounted to the rear of server racks, absorbing heat from server exhaust and transferring it through a heat exchanger before returning cooled air to the data hall.

The closed-loop design supports higher rack densities while improving energy performance.

The cooling equipment was installed while the data centre remained live, a process described by Wolfgang Voigt, Münchenstein Data Center Site Manager at NorthC, as “like open-heart surgery.”

Focus on efficiency and future expansion

NorthC reports that energy consumption at the site has fallen by about 80% following the cooling upgrade and broader infrastructure improvements.

The facility now supports GPU-based clusters, hybrid-cloud environments, and high-density workloads, while maintaining compliance with Swiss data protection requirements.

Wolfgang says, “Adopting the energy-efficient RDHx technology has been a game-changer for us. The fact that it enables high-density computing while reducing energy consumption makes it a compelling choice to meet AI and HPC requirements.”

The upgraded design also accommodates future development, including additional rack capacity or a shift towards liquid or direct-to-chip cooling.

NorthC says it continues to pursue its long-term sustainability goals through efficiency measures and ongoing optimisation of existing sites.

Colin Rowlands, European Technical Support at USystems, notes, “Installing the basic infrastructure for our cooling solutions in a data centre, whether in the entire data centre or just part of it, makes upgrading easy.

"The joint solution, which we are very proud of, provides NorthC with future-proof and flexible infrastructure.”

For more from NorthC, click here.

Joe Peck - 19 November 2025

Data Centre Business News and Industry Trends

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Insights into Data Centre Investment & Market Growth

Vertiv, Caterpillar to expand joint energy offerings for AI DCs

Vertiv, a global provider of critical digital infrastructure, and Caterpillar, a manufacturer of construction equipment, have agreed to collaborate on energy optimisation for AI data centres, combining power generation, distribution, and cooling expertise in a set of integrated reference designs.

The aim is to support operators facing rising demand for on-site power and thermal management as AI workloads expand.

The undertaking will connect Vertiv’s power distribution and cooling portfolio with Caterpillar’s and Solar Turbines’ experience in power generation and combined cooling, heat, and power (CCHP).

The companies intend to offer pre-designed architectures intended to streamline deployment and standardise performance across sites.

Integrated approach to power and cooling

Caterpillar and Solar Turbines will provide natural gas turbines and reciprocating engines for scalable on-site power and thermal output for CCHP configurations.

Vertiv will contribute power and cooling technologies packaged as modular, pre-designed blocks to reduce design time and support consistent deployment across facilities.

According to the companies, this approach is intended to shorten deployment time, improve operational efficiency, and offer global lifecycle support through established service networks.

Gio Albertazzi, CEO at Vertiv, comments, “This collaboration with Caterpillar and Solar Turbines is a cornerstone of our 'Bring Your Own Power & Cooling' strategy and aligns seamlessly with our grid-to-chip framework by offering resilient, on-site power generation solutions. This is optimal for customers looking to reduce or eliminate grid dependence.

“By combining our complementary technologies, portfolios, and expertise, we are enabling coordinated integration. Our pre-engineered, interoperability-tested building blocks let customers execute design, build, and deploy concurrently, with predictable system performance.”

Jason Kaiser, Group President of Caterpillar Power & Energy, adds, “As AI-driven workloads continue to accelerate, the demand for robust and scalable power infrastructure and cooling is becoming increasingly critical. Our collaboration with Vertiv will enable us to deliver integrated, on-site energy solutions that lower PUE and meet customers’ evolving needs.”

The companies state that the undertaking will support data centre operators facing energy constraints by helping them deploy AI-ready facilities with improved efficiency and more predictable commissioning.

A Memorandum of Understanding between Vertiv and Caterpillar establishes the framework for further development of this joint ecosystem.

For more from Vertiv, click here.

Joe Peck - 19 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

Why cooling design is critical to the cloud

In this article for DCNN, Ross Waite, Export Sales Manager at Balmoral Tanks, examines how design decisions today will shape sustainable and resilient cooling infrastructure for decades to come:

Running hot and running dry?

Driven by the surge in AI and cloud computing, new data centres are appearing at pace across Europe, North America, and beyond. Much of the debate has focused on how we power sites, yet there is another side to the story, one that determines whether those billions invested in servers actually deliver: cooling.

Servers run hot, 24/7, and without reliable water systems to manage that heat, even the best-connected facilities cannot operate as intended. In fact, cooling is fast becoming the next frontier in data centre design and the decisions made today will echo for decades.

A growing thirst

Data centres are rapidly emerging as one of the most significant commercial water consumers worldwide. Current global estimates suggest that facilities already use over 560 billion litres of water annually, with that figure set to more than double to 1,200 billion litres by 2030 as AI workloads intensify.

The numbers at an individual site are equally stark. A single 100 MW hyperscale centre can use up to 2.5 billion litres per year - enough to supply a city of 80,000 people. Google has reported daily use of more than 2.1 million litres at some sites, while Microsoft’s 2023 global consumption rose 34% year-on-year to reach 6.4 million cubic metres. Meta reported 95% of its 2023 water use - some 3.1 billion litres - came from data centres.

The majority of this is consumed in evaporative cooling systems, where 80% of drawn water is lost to evaporation and just 20% returns for treatment. While some operators are trialling reclaimed or non-potable sources, these currently make up less than 5% of total supply.

The headline numbers can sound bleak, but water use is not inherently unsustainable. Increasingly, facilities are moving towards closed-loop cooling systems that recycle water for six to eight months at a time, reducing continuous draw from mains supply. These systems require bulk storage capacity, both for the initial fill and for holding treated water ready for reuse.

Designing resilience into water systems

This is where design choices made early in a project pay dividends. Consultants working on new builds are specifying not only the volume of water storage or the type of system that should be used but also the standards to which they are built. Tanks that support fire suppression, potable water, and process cooling need to meet stringent criteria, often set by insurers as well as regulators.

Selecting materials and coatings that deliver 30-50 years of service life can prevent expensive retrofits and reassure both clients and communities that these systems are designed to last. Smart water management, in other words, begins not onsite, but on the drawing board.

For consultants who are designing the build specifications for data centres, water is more than a technical input; it is a reputational risk. Once a specification is signed off and issued to tender, it is rarely altered. Getting it right first time is essential. That means selecting partners who can provide not just tanks, but expertise: helping ensure that water systems meet performance, safety, and sustainability criteria across decades of operation.

The payback is twofold. First, consultants safeguard their client’s investment by embedding resilience from the start. Second, they position themselves as trusted advisors in one of the most scrutinised aspects of data centre development. In a sector where projects often run to tens or hundreds of millions of pounds, this credibility matters.

Power may dominate the headlines, but cooling - and by extension water - is the silent foundation of the digital economy. Without it, AI models do not train, cloud services do not scale, and data stops flowing. The future of data centres will be judged not only on how much power they consume, but on how intelligently they use water - and that judgement begins with design.

If data centres are the beating heart of the modern economy, then water is the life force that keeps them alive. Cooling the cloud is not an afterthought; it is the future.

Joe Peck - 17 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

ABB supplies power tech for Applied Digital's AI factory

ABB, a multinational corporation specialising in industrial automation and electrification products, has expanded its collaboration with Applied Digital, an operator of high-performance data centres, to supply power infrastructure for the company’s second AI factory campus in North Dakota, USA.

The latest order, booked in late 2025, covers new medium-voltage electrical architecture designed to support the rising power demands of AI workloads.

Financial terms have not been disclosed.

Powering the AI factory

Applied Digital’s Polaris Forge 2 campus, located near Harwood, North Dakota, is planned to deliver 300 MW of capacity across two buildings due to enter operation in 2026 and 2027. The site is being developed with scope for further expansion.

ABB will provide both low- and medium-voltage electrical systems intended to help the facility achieve high efficiency levels and a low projected PUE.

Todd Gale, Chief Development Officer at Applied Digital, says, “Our partnership with ABB reflects Applied Digital’s commitment to redefining what is possible in data centre scale and performance.

“Polaris Forge 2 represents the next evolution of our AI factory model - beginning with two 150-megawatt buildings with the ability to scale - solidifying our position as a leader in delivering high-performance, energy-efficient AI infrastructure.”

ABB Smart Power President Massimiliano Cifalitti comments, “As AI reshapes data centres, ABB is working with leading digital infrastructure innovators to introduce a new generation of advanced power system solutions.

“The medium voltage architecture developed with Applied Digital is a big step forward for large-scale AI facilities. Working together closely from the start enabled both teams to identify opportunities to drive higher efficiency, performance, and reliability, along with lower costs and faster time to market.”

Applied Digital has reported that the first 200 MW of capacity at Polaris Forge 2 will be leased to a US-based hyperscaler.

The companies’ partnership began in June 2025 with the development of Applied Digital’s first 400 MW AI campus, Polaris Forge 1, in Ellendale, North Dakota.

Both campuses use ABB’s HiPerGuard medium-voltage UPS and medium-voltage switchgear. Moving power distribution to medium voltage using this approach is intended to increase power density, improve efficiency, and support scaling in larger blocks, while also reducing cabling requirements.

For more from ABB, click here.

Joe Peck - 17 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

Products

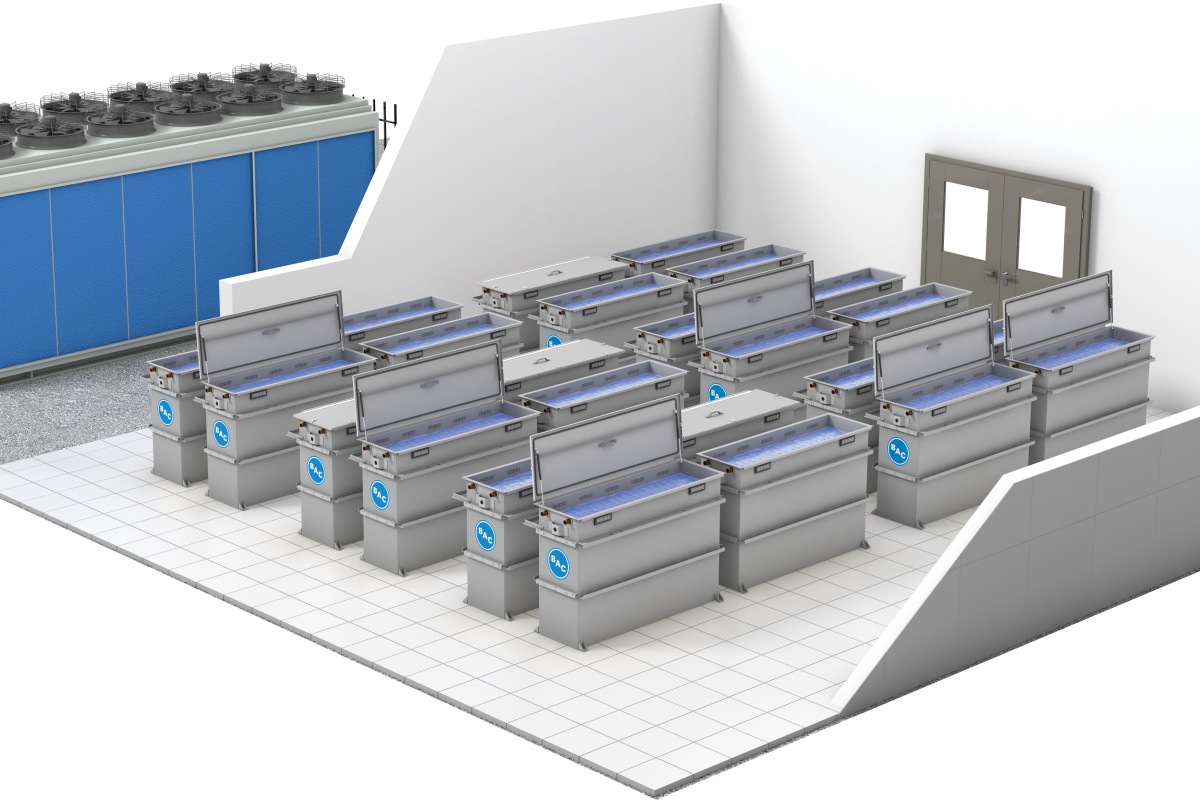

BAC releases upgraded immersion cooling tanks

Baltimore Aircoil Company (BAC), a provider of data centre cooling equipment, has introduced an updated immersion cooling tank for high-performance data centres, incorporating its CorTex technology to improve reliability, efficiency, and support for high-density computing environments.

The company says the latest tank has been engineered to provide consistent performance with minimal maintenance, noting its sealed design has no penetrations below the fluid level, helping maintain fluid integrity and reduce leakage risks.

Dual pumps are included for redundancy and the filter-free configuration removes the need for routine filter replacement.

Design improvements for reliability and ease of operation

The tanks are available in four sizes - 16RU, 32RU, 38RU, and 48RU - allowing operators to accommodate a range of immersion-ready servers. Air-cooled servers can also be adapted for immersion use.

Each unit supports server widths of 19 and 21 inches (~48 cm and ~53 cm) and depths up to 1,200 mm, enabling higher rack densities within a smaller footprint than traditional air-cooled systems.

BAC states that the design can support power usage effectiveness levels of up to 1.05, depending on the wider installation.

The system uses dielectric fluid to transfer heat from servers to the internal heat exchanger, while external circuits can run on water or water-glycol mixtures.

Cable entry points, the lid, and heat-exchanger connections are fluid-tight to help prevent contamination.

The immersion tank forms the indoor component of BAC’s Cobalt system, which combines indoor and outdoor cooling technologies for high-density computing.

The system can be paired with BAC’s evaporative, hybrid, adiabatic, or dry outdoor equipment to create a complete cooling configuration for data centres managing higher-powered servers and AI-driven workloads.

For more from BAC, click here.

Joe Peck - 17 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

ZutaCore unveils waterless end-of-row CDUs

ZutaCore, a developer of liquid cooling technology, has introduced a new family of waterless end-of-row (EOR) coolant distribution units (CDUs) designed for high-density artificial intelligence (AI) and high-performance computing (HPC) environments.

The units are available in 1.2 MW and 2 MW configurations and form part of the company’s direct-to-chip, two-phase liquid cooling portfolio.

According to ZutaCore, the EOR CDU range is intended to support multiple server racks from a single unit while maintaining rack-level monitoring and control.

The company states that this centralised design reduces duplicated infrastructure and enables waterless operation inside the white space, addressing energy-efficiency and sustainability requirements in modern data centres.

The cooling approach uses ZutaCore’s two-phase, direct-to-chip technology and a low-global warming potential dielectric fluid. Heat is rejected into the facility without water inside the server hall, aiming to reduce condensation and leak risk while improving thermal efficiency.

My Truong, Chief Technology Officer at ZutaCore, says, “AI data centres demand reliable, scalable thermal management that provides rapid insights to operate at full potential. Our new end-of-row CDU family gives operators the control, intelligence, and reliability required to scale sustainably.

"By integrating advanced cooling physics with modern RESTful APIs for remote monitoring and management, we’re enabling data centres to unlock new performance levels without compromising uptime or efficiency.”

Centralised cooling and deployment models

ZutaCore states that the systems are designed to support varying availability requirements, with hot-swappable components for continuous operation.

Deployment options include a single-unit configuration for cost-effective scaling or an active-standby arrangement for enterprise environments that require higher redundancy levels.

The company adds that the units offer encrypted connectivity and real-time monitoring through RESTful APIs, aimed at supporting operational visibility across multiple cooling units.

The EOR CDU platform is set to be used in EGIL Wings’ 15 MW AI Vault facility, as part of a combined approach to sustainable, high-density compute infrastructure.

Leland Sparks, President of EGIL Wings, claims, “ZutaCore’s end-of-row CDUs are exactly the kind of innovation needed to meet the energy and thermal challenges of AI-scale compute.

"By pairing ZutaCore’s waterless cooling with our sustainable power systems, we can deliver data centres that are faster to deploy, more energy-efficient, and ready for the global scale of AI.”

ZutaCore notes that its cooling technology has been deployed across more than forty global sites over the past four years, with users including Equinix, SoftBank, and the University of Münster.

The company says it continues to expand through partnerships with organisations such as Mitsubishi Heavy Industries, Carrier, and ASRock Rack, including work on systems designed for next-generation AI servers.

Joe Peck - 14 November 2025

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173