Innovations in Data Center Power and Cooling Solutions

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

Products

GoodWe introduces liquid-cooled energy storage system

GoodWe, an inverter manufacturer and smart energy system provider, has launched the ESA Series, an all-in-one, liquid-cooled energy storage system designed for commercial and industrial (C&I) applications.

The unit provides 125kW nominal output power and 261kWh storage capacity, as well as integrating the power conversion system, battery cells, energy management system, and battery management system into a single cabinet.

The system can be scaled by connecting up to 15 units in parallel, supporting a maximum total capacity of 3.91MWh in grid-connected scenarios. GoodWe says the design allows for simplified installation, operation, and maintenance whilst offering flexible expansion.

Performance and safety features

The ESA cabinet has a footprint of 1.47m² and an energy density of 177.6kWh per square metre, aimed at sites with limited space. It incorporates 314Ah lithium iron phosphate (LFP) cells and liquid cooling technology to regulate temperatures across the system. The storage supports 6,000 cycles and operates in temperatures from -25°C to 55°C.

The ESA 125kW/261kWh was tested under UL 9540A methodology and includes multiple safety measures, such as smoke detection, thermal sensors, combustible gas monitoring, and humidity control with automatic dehumidification.

Fire protection uses both active and passive approaches, including integrated aerosol suppression modules. TÜV Rheinland has certified the system for environmental adaptability across climatic, mechanical, chemical, electromagnetic, and specialised scenarios.

Deployment examples

GoodWe reports that early projects in China have demonstrated reductions in energy costs and improved operational efficiency. At its Guangde manufacturing site, nine ESA cabinets were installed in parallel to provide large-scale storage. Another installation in De’an combined seven cabinets with wind and solar power to support an energy storage project for heavy-duty truck charging.

The system supports operating modes including peak shaving, demand management, energy trading participation, and off-grid backup power. In on-grid deployments, ESA units can be combined with GoodWe GT Series inverters and managed by the SEC3000C Smart Energy Controller to support up to 40 string inverters.

Joe Peck - 21 August 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

Products

Trane adds CRAH units to DC cooling portfolio

Trane, an American manufacturer of heating, ventilation, and air conditioning (HVAC) systems, has expanded its data centre thermal management range with the addition of a Computer Room Air Handler (CRAH) system.

The unit is designed to maintain airflow and temperature conditions for servers and other electronic equipment, aiming to support operational uptime while reducing energy use.

The CRAH system is equipped with Trane’s Symbio controller, which provides a broad capacity range and customisable configurations.

The controller enables leader designation and dynamic reassignment for up to 32 units, allowing continuous operation and access to digital tools for lifecycle management.

According to Trane, the new airside system is intended for both colocation and hyperscale data centre operators seeking flexible integration into existing or new-build facilities.

Steve Obstein, Vice President and General Manager, Data Centres, Trane Technologies, says, “Expansion of our airside offer gives our colo and hyperscale customers greater flexibility for configuring custom systems and addresses the growing trend toward a single-source solutions provider.”

Integration and lifecycle support

The CRAH addition is part of Trane’s wider approach to unifying and integrating thermal management systems through smart controls.

The company offers local service teams across North America and remote monitoring capabilities for predictive maintenance and operational oversight.

Recent updates to Trane’s thermal management portfolio include:

• Scalable liquid cooling platforms• A fan coil wall platform• Larger capacity and higher ambient temperature air-cooled chillers

The CRAH system has been developed to operate alongside these technologies as part of a consolidated data centre cooling strategy, with the aim of improving efficiency, reliability, and sustainability.

For more from Trane, click here.

Joe Peck - 12 August 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

BSRIA first UKAS-accredited provider for BTS 4/2024

BSRIA, a consultancy and testing organisation, has become the first organisation to receive UKAS accreditation in accordance with BTS 4/2024 for airtightness testing of Raised Access Plenum Floors (RAPFs), following a successful ISO 17025 audit earlier in 2024.

The accreditation formally extends BSRIA’s scope of approved activities and introduces an industry-recognised methodology for testing RAPFs, which play a key role in airflow management in data centres.

Chris Knights, BSRIA Building Performance Evaluation Business Manager and lead author of BTS 4/2024, comments, “The UKAS accreditation ensures we continue to provide independent testing to the highest standards of quality, repeatability, and traceability.

"This is a significant advancement, enabling the industry to adopt a dedicated standard that supports higher-performing building services for owners and operators.”

BTS 4/2024 standard

The accreditation follows the introduction of BTS 4/2024 Airtightness Testing of Raised Access Plenum Floors, which sets out a methodology for measuring RAPF air leakage.

The standard is designed to support efficient airflow management by ensuring conditioned air in underfloor voids is directed to the intended occupied areas rather than escaping through cavities, risers, stairwells, or other adjacent spaces.

RAPFs are widely used in modern construction, particularly in data centres, where optimised airflow is important for both cooling performance and energy efficiency.

BTS 4/2024 supersedes previous guidance, BG 65/2016 Floor Plenum Airtightness – Guidance and Testing Methodology, and incorporates clearer guidance and refined testing processes developed in response to industry feedback.

Chris continues, “An effectively constructed and sealed raised access plenum floor is essential for achieving the air distribution performance intended during the design phase.

"The methodology in BTS 4/2024 provides clear criteria and a step-by-step process for verifying as-built performance.

"With increasing demand for high-performing environments such as data centres, specifying BTS 4/2024 supports effective air distribution and helps ensure RAPFs deliver on design intent.”

Joe Peck - 11 August 2025

Data Centre Build News & Insights

Data Centre Infrastructure News & Trends

Data Centre Projects: Infrastructure Builds, Innovations & Updates

Innovations in Data Center Power and Cooling Solutions

Joule, Caterpillar, Wheeler to power Utah DC

Joule Capital Partners, an infrastructure company, Caterpillar, a manufacturer of construction equipment, and Wheeler Machinery, a dealer of heavy construction equipment, have jointly announced an agreement to power Joule’s High Performance Compute Data Center Campus in Utah.

Joule says it aims to create the largest single campus in Utah.

Bringing multiple gigawatts of capacity to Utah

This initiative will provide four gigawatts of total energy to the centre of the Intermountain West.

The project will deliver prime power and integrated combined cooling heat and power (CCHP) systems with a by-design liquid cooling architecture.

Powered by a fleet of Caterpillar’s latest G3520K generator sets and support equipment, the distributed generation system produces electricity and captures waste heat to power and cool high-density server systems.

The provision includes 1.1 gigawatt hours of grid forming battery energy storage along with backup power generation served by diverse fuel sources.

Due to Caterpillar’s US-based manufacturing footprint, the full generation package should be able to be delivered ahead of other generation technologies. This speed-to-power advantage could be critical for meeting the growth in demand for compute capacity.

Beyond the gensets, this integrated system includes the controls, switchgear, inverters, energy storage, and CCHP, providing a total power provision for the Joule data centre.

Caterpillar and Wheeler will also provide service and support for the products and systems, aiming to ensure uptime and availability targets are met.

Comments

“This project represents the core of Joule’s mission: to deliver artificial-intelligence-(AI)-ready compute capacity by pairing world-class data centre campuses with reliable, on-demand power,” says David Gray, President of Joule Capital Partners.

“By combining Caterpillar’s advanced energy systems with Wheeler’s local expertise, we can bring gigawatt-scale capacity to market faster and more efficiently than ever before, ensuring our tenants have the power and reliability they need to thrive in the next generation of high-performance computing.”

Melissa Busen, Senior Vice President of Electric Power at Caterpillar, adds, “Caterpillar is uniquely positioned to tackle the growing energy needs for artificial intelligence and the evolving needs of modern infrastructure.

"This project is a perfect example of how we can deliver fast, reliable power generation to our customers through integrated energy solutions. We are proud to work with Joule and Wheeler to help bring this project to life.”

Bryan Campbell, CEO of Wheeler Machinery, claims, “This strategic alliance between Joule, Caterpillar, and Wheeler brings together world-class engineering, local expertise, and visionary energy design.

“We’re proud to help deliver a resilient solution ready to meet future compute demands and set a new standard for data centre infrastructure.”

Joe Peck - 8 August 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Mayflex signs distribution agreement with Schleifenbauer

Mayflex, a UK-based distributor of converged IP infrastructure, networking, and electronic security products, has announced a new distribution agreement with Schleifenbauer, adding the Netherlands-based manufacturer’s power distribution units (PDUs) and energy management tools to the Elevate brand’s data centre infrastructure portfolio.

The partnership aims to support Mayflex’s ongoing focus on high-performance computing (HPC) and data centre (DC) environments, with a particular emphasis on providing equipment that is efficient, scalable, and compliant with European standards.

Schleifenbauer, which designs and manufactures its products in the Netherlands, will supply intelligent PDUs and related energy management software for integration into the Elevate range.

The collaboration hopes to enhance delivery times and flexibility, particularly for UK and Ireland customers.

Product and operational features

The partnership will see the inclusion of several features designed to improve operational performance and ease of use across data centre projects:

• European manufacturing — All Schleifenbauer equipment is produced in the Netherlands, allowing for consistent quality control, shorter lead times, and full EU regulatory compliance.

• Customisable production — The company offers a flexible manufacturing model with no minimum order requirements. This allows Mayflex customers to request individual units for trial projects, or bulk orders for larger-scale deployment, while maintaining consistent performance standards.

• Energy monitoring software — Schleifenbauer’s energy management platform is available at no extra cost. The software enables real-time monitoring and optimisation of energy usage across installations.

• Hot-swappable modules — PDUs include hot-swappable control components, enabling updates or maintenance without downtime.

• Short lead times — Schleifenbauer’s production model supports faster turnaround and delivery times, which Mayflex aims to leverage across the Elevate product range.

Comments from the companies

Simon Jacobs, Product Manager at Mayflex, says, “We’re excited to welcome Schleifenbauer as a technology partner to our Elevate brand. Their intelligent power solutions are a perfect fit for our growing data centre portfolio.

"The combination of European manufacturing, rapid lead times, and advanced features - like hot-swappable modules and free energy management software - makes this a compelling proposition for our customers.”

Stuart Edmonds, UK and Ireland Sales Manager at Schleifenbauer, adds, “Partnering with Mayflex is a strategic move that allows us to expand our reach in the UK and Ireland.

"Mayflex’s reputation for technical excellence and customer service aligns perfectly with our values. Together, we’re well-positioned to support the evolving needs of the HPC and data centre markets.”

Joe Peck - 31 July 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

Aligned collaborates with Divcon for its Advanced Cooling Lab

Divcon Controls, a US provider of building management systems and electrical power monitoring systems for data centres and mission-critical facilities, has announced its role in the development of Aligned Data Centers’ new Advanced Cooling Lab in Phoenix, Arizona, where it served as the controls vendor for the facility.

The project marks a step forward in the design and management of liquid-cooled infrastructure to support artificial intelligence (AI) and high-performance computing (HPC) workloads.

The lab, which opened recently, is dedicated to testing advanced cooling methods for GPUs and AI accelerators. It reflects a growing need for more efficient thermal management as data centre density increases and energy requirements rise.

“As the data centre landscape rapidly evolves to accommodate the immense power and cooling requirements of AI and HPC workloads, the complexities of managing mechanical systems in these environments are escalating,” says Kevin Timmons, Chief Executive Officer of Divcon Controls.

“Our involvement with Aligned Data Centers' Advanced Cooling Lab has provided us with invaluable experience at the forefront of liquid cooling technology.

"We are actively developing and deploying advanced control platforms that not only optimise the performance of these systems, but also contribute to long-term sustainability goals.”

Divcon Controls has focused its work on managing the added complexity that liquid cooling introduces, including:

• Precise thermal control — Managing coolant flow, temperature, and pressure to improve heat transfer efficiency and reduce energy consumption.

• Integration with mechanical infrastructure — Coordinating the performance of pumps, heat exchangers, cooling distribution units (CDUs), and leak detection systems within a unified control framework.

• Load-responsive adjustment — Adapting cooling output in real time to match fluctuating IT loads, helping maintain optimal operating conditions while limiting energy waste.

• Visibility and predictive maintenance — Providing operators with detailed analytics on system performance to support proactive maintenance and longer equipment life.

• Support for hybrid environments — Enabling the transition between air and liquid cooling within the same facility, as demonstrated at Aligned’s lab.

As more facilities transition to hybrid and liquid-cooled architectures, Divcon Controls says it is focusing on delivering control systems that enhance energy efficiency, reduce operational risk, and ensure long-term asset reliability.

“Our collaboration with industry leaders like Aligned Data Centers underscores our commitment to innovation and to solving the most pressing challenges in data centre infrastructure,” continues Kevin.

“Divcon Controls is proud to be at the forefront of developing intelligent control platforms for the next generation of high-density, AI-powered data centres, with environmental performance front of mind.”

For more from Aligned, click here.

Joe Peck - 29 July 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

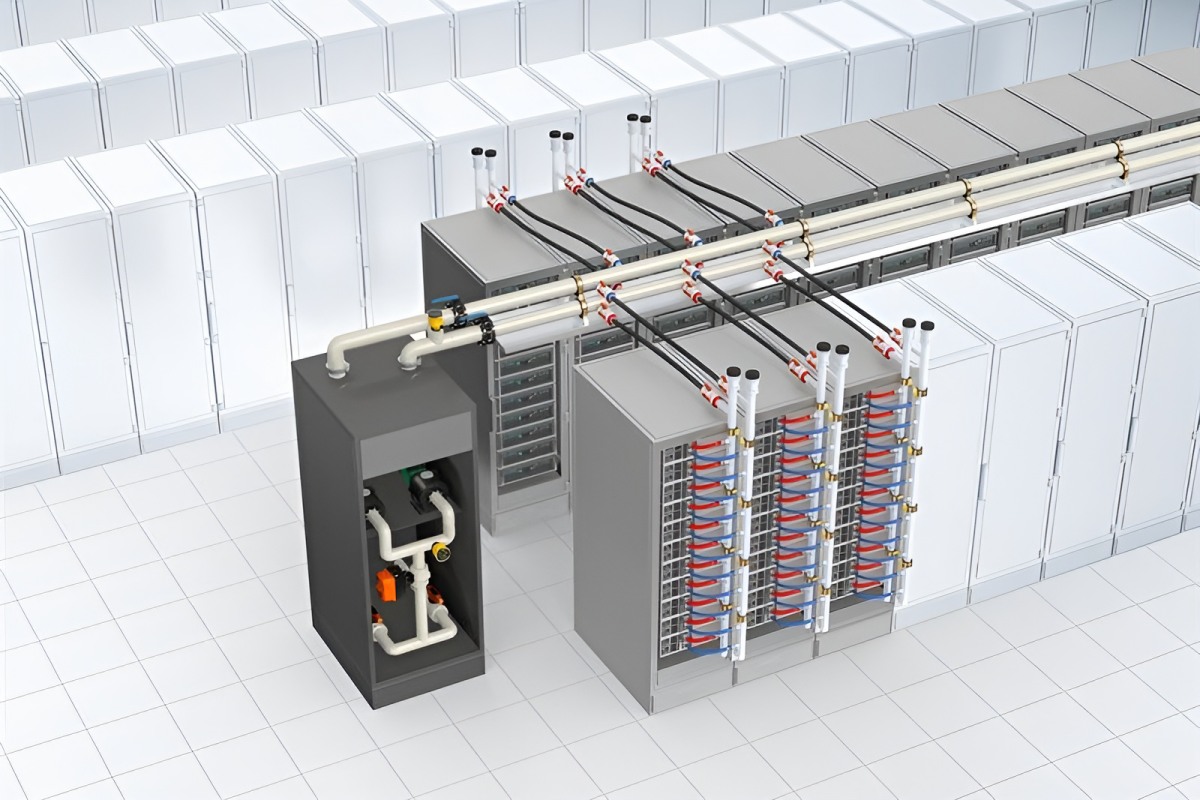

GF introduces first-ever full-polymer Quick Connect Valve

The Quick Connect Valve 700 is a patented dual-ball valve engineered with the aim of enhancing safety, efficiency, and sustainability in Direct Liquid Cooling (DLC) systems.

The company claims that, "as the first all-polymer quick connect valve for data centre applications, it is 50% lighter and facilitates 25% better flow compared to conventional metal alternatives while offering easy, ergonomic handling."

As demand for high-density, high-performance computing grows, DLC is reportedly becoming a preferred method for thermal management in next-generation data centres.

By transporting coolant directly to the chip, DLC can improve thermal efficiency compared to air-based methods. A key component in this setup is the Technology Cooling System (TCS), which distributes coolant from the Cooling Distribution Unit (CDU) to individual server racks.

To support this shift, manufacturer of plastic piping systems, valves, and fittings GF has developed the Quick Connect Valve 700, a fully plastic, dual-ball valve engineered for direct-to-chip liquid cooling environments.

Positioned at the interface between the main distribution system and server racks, the valve is intended to enable fast, safe, and durable coolant connections in mission-critical settings.

Built on GF’s Ball Valve 546 Pro platform, the Quick Connect Valve 700 features two identical PVDF valve halves and a patented dual-interlock lever.

This mechanism ensures the valve can only be decoupled when both sides are securely closed, aiming to minimise fluid loss and maximise operator safety during maintenance. Its two-handed operation further reduces the risk of accidental disconnection.

The valve is made of corrosion-free polymer, which is over 50% lighter than metal alternatives and provides a UL 94 V-0 flammability rating.

Combined with the ergonomic design of its interlocking mechanism, the valve is, according to the company, easy to handle during installation and operation.

At the same time, its full-bore valve design seeks to ensure an optimal flow profile and a reduced pressure drop of up to 25% compared to similar metal products.

The product has a minimum expected service life of 25 years.

“With the Quick Connect Valve 700, we’ve created a critical link in the DLC cooling loop that’s not only lighter and safer, but more efficient,” claims Charles Freda, Global Head of Data Centers at GF.

“This innovation builds on our long-standing thermoplastic expertise to help operators achieve the performance and uptime their mission-critical environments demand.”

The Quick Connect Valve 700 has been assessed with an Environmental Product Declaration (EPD) according to ISO 14025 and EN 15804.

An EPD is a standardised, third-party verified document that uses quantified data from Life Cycle Assessments to estimate environmental impacts and enable comparisons between similar products.

For more from GF, click here.

Joe Peck - 28 July 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Sponsored

Whitepaper: Can AI solve the data centre energy paradox?

As the global demand for data continues to surge, data centres are rapidly scaling up, driven in large part by artificial intelligence (AI) and machine learning. Yet, whilst AI is accelerating innovation, it is also intensifying the energy challenge facing operators and infrastructure providers worldwide.

In a new whitepaper from Hitachi Energy, the company explores this very paradox: can AI help to solve the sustainability and efficiency issues that it, in part, is responsible for creating?

The technical brief, entitled Powering data centres sustainably in an AI world, delves into AI’s growing influence across the digital infrastructure sector, its impact on energy demand, and how it could enable a more efficient, sustainable future.

In particular, it examines AI’s potential to optimise power consumption, streamline cooling strategies, and support smarter energy distribution across increasingly complex data centre estates.

It also considers how AI can contribute to the broader clean energy transition, including integration with renewable energy sources and smarter grid interactions, among other key issues which are essential as the industry faces mounting pressure to align with global net zero goals.

For data centre owners, operators, and energy stakeholders alike, the whitepaper offers timely insights into a future where AI could become both the driver and the solution for sustainable digital growth.

You can read the full whitepaper here.

For more from Hitachi, click here.

Joe Peck - 25 July 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

Products

Chatsworth launches new eConnect PDUs

Chatsworth Products (CPI), a US-based manufacturer of IT infrastructure equipment, has launched a new addition to its eConnect Power Distribution Unit (PDU) portfolio, introducing a QuadLock outlet design that the company says provides improved outlet compatibility and power reliability for high-density, high-performance data centres.

The new eConnect PDUs with QuadLock outlets aim to support a range of infrastructure requirements, including AI- and GPU-based computing environments, as well as liquid-cooled systems. The units are designed to enhance adaptability, reduce operational risk, and streamline deployment by integrating four outlet types - C13, C15, C19, and C21 - within a single chassis.

CPI’s new offering supports all four outlet types with built-in locking mechanisms, without the need for proprietary power cords.

“With data centres facing rapid technological advancements, including the proliferation of GPU and AI workloads, infrastructure flexibility and power reliability are more critical than ever,” argues Ashish Moondra, Senior Director of Electronics and Software at CPI.

“eConnect PDUs with QuadLock Outlets empower our customers to quickly adapt to changing equipment requirements without sacrificing performance or uptime.”

Key features of the eConnect PDU with QuadLock Outlets include:

• Four-outlet compatibility — One unit supports C13, C15, C19, and C21 outlet types, increasing equipment compatibility and reducing the need for multiple PDU models.

• Secure locking mechanism — Each outlet includes integrated locking to prevent accidental disconnections, including in high-vibration or high-traffic environments.

• High-power support — Systems can deliver up to 57.5kW per cabinet with 100A input capacity, supporting intensive workloads.

• Colour-coded outlets — Aids in load balancing and troubleshooting by making outlet identification easier.

• Flexible integration — Compatible with all six CPI eConnect PDU models - Basic, Metered, Monitored, Monitored Pro, Switched, and Switched Pro - and can be pre-installed into CPI cabinets for quicker deployment.

The modular design is intended to reduce PDU redundancy, simplify inventory management, and support a scalable approach to data centre infrastructure. CPI also highlights the product’s contribution to sustainability goals by reducing waste through long-term compatibility and reusability.

The new PDUs will be available from 7 July 2025 through CPI’s global network of distribution partners.

Joe Peck - 23 July 2025

Data Centre Build News & Insights

Innovations in Data Center Power and Cooling Solutions

Renewables and Energy: Infrastructure Builds Driving Sustainable Power

Sustainable Infrastructure: Building Resilient, Low-Carbon Projects

Allegro argues case for sustainable energy storage

As data centre expansion accelerates to meet the demands of AI, cryptocurrencies, and cloud services, Australia-based developer Allegro Energy is arguing for the relevance and applicability of its long-duration energy storage (LDES) technology in "enabling scalable, sustainable energy solutions tailored to the unique needs of modern data centres."

With data centres operating on consistent, high-load profiles, they are uniquely positioned to benefit from a clean power strategy that combines renewable generation with long-duration energy storage.

Allegro Energy’s modular, scalable, and environmentally-friendly battery systems, according to the company, "present a solution that overcomes the prohibitive cost, scalability, and sustainability challenges associated with traditional lithium-ion or vanadium-based systems."

• Modularity & scalability — Allegro’s LDES systems are designed to grow in parallel with a data centre’s needs, allowing incremental investment and deployment.

• Renewable compatibility — The system pairs with solar and wind energy, aiming to help data centres navigate grid volatility and peak pricing while advancing towards net zero carbon targets.

• Climate-friendly storage chemistry — The water-based electrolyte technology is not resource-constrained, hoping to offer a low-impact alternative that can be deployed at scale.

“The exponential growth of generative AI, cloud computing, and digital services has made energy a critical chokepoint in data infrastructure,” says Thomas Nann, CEO of Allegro Energy.

“We believe the future of high-performance computing does not need to come at the cost of the planet. With our technology, data centres can be powered entirely by renewables, supported by reliable, cost-effective long-duration storage.”

Allegro Energy’s proprietary, locally manufactured micro-emulsion electrolyte technology eliminates the need for scarce or rare metals, reducing fire risk and allowing for extended storage durations at a lower cost.

Joe Peck - 18 July 2025

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173