Innovations in Data Center Power and Cooling Solutions

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

"One size does not fit all"

By Louis McGarry, Sales & Marketing Director, Centiel

One of the most common questions I get asked is ‘What size UPS do you sell?’ The answer is that Centiel's multi-award winning, true modular UPS StratusPower can be made available in any size that the data centre needs. For facilities where the future load is uncertain, Centiel's team of trusted advisors work hand-in-hand with customers to design an appropriate power protection solution which is flexible to be able to scale up or down, depending on requirements.

StratusPower has been developed by Centiel's experts to be the most customisable UPS product on the market. The company can be led by access limitation or limited space to achieve the most power in the tightest spaces. This means Centiel can customise the UPS to fit a range physical axis or even integrate into a containerised pod.

StratusPower can also be configured to accommodate the electrical infrastructure whether that’s top and bottom cable entry or busbar connections. As a result, StratusPower can be installed into any type of data centre from edge facilities to multi megawatt operations.

The only elements which remain fixed are the technological benefits of StratusPower which are always present regardless of the size of the installation and include: high efficiency, market leading availability, scalability, reliability and sustainability.

StratusPower is also durable due to its topology and innovative hardware and firmware design, meaning components are not stressed and last longer. Instead of replacing consumables such as filter capacitors and cooling fans every four to six years, replacements are needed every 15 years, or just once during their entire 30-year design life. This is important as a data centre has a design life of typically 25 to 30 years.

With proven '9 nines' availability, StratusPower effectively eliminates system downtime. Class leading 97.6% on-line efficiency minimises running costs, and true 'hot swap' modules eliminate human error and allowing modules to be tested fully while connected to the grid in the hot frame and disconnected physically from the load, increasing safety during upgrades.

The key point is StratusPower is ready designed as the most advanced UPS available and yet the build and ultimate solution is totally flexible and dependent on actual needs. The infrastructure and racks accept modules of the same rating which means modules from a lightly loaded area can also be re-deployed to parts of the data centre needing more power protection. These scalable and flexible UPS cabinets therefore, enable future load changes to be easily accommodated by adding or removing UPS modules as required. A data centre will never outgrow a well specified StratusPower UPS, and it can be constantly rightsized to ensure it always operates at the optimal point in its efficiency curve.

Further, StratusPower is also adaptable and has been designed to integrate with different energy management protocols, and is future ready to accept alternative energy sources.

With its innovative topology, advanced energy management features, and unmatched scalability, StratusPower is the ultimate UPS system for data centre operators looking to optimise their power infrastructure. StratusPower is offered in a power range from 50 to 1,500 kW in one cabinet, and can be paralleled for 3,750 kW critical power protection.

For more from Centiel, click here.

Simon Rowley - 6 November 2024

Cooling

Data Centres

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

News

Schneider Electric acquires liquid cooling company

Schneider Electric has announced that it has signed an agreement to acquire a controlling interest in Motivair Corporation, a company that specialises in liquid cooling and advanced thermal management solutions for high performance computing systems.

The advent of Generative-AI and the introduction of Large Language Models (LLMs) have been additional catalysts driving enhanced power needs to support increased digitisation across end-markets. This shift to accelerated computing is resulting in new data centre architectures requiring more efficient cooling solutions, particularly liquid cooling, as traditional air cooling alone cannot mitigate the higher heat generated as a result.

As the compute within data centres becomes higher-density, the need for effective cooling will grow, with multiple market and analyst forecasts predicting growth in liquid cooling solutions in excess of +30% CAGR in the coming years. This transaction strengthens Schneider Electric’s portfolio of direct-to-chip liquid cooling and high-capacity thermal solutions, enhancing existing offerings and furthering innovation in cooling technology.

Headquartered in Buffalo, New York, Motivair was founded in 1988 and currently has over 150 employees. Leveraging its strong engineering competency and deep domain expertise, Motivair has a range of offers including Coolant Distribution Units (CDUs), Rear Door Heat Exchangers (RDHx), Cold Plates and Heat Dissipation Units (HDUs), alongside Chillers for thermal management. Motivair provides its customers with a portfolio to meet the thermal challenges of modern computing technology.

While liquid cooling is not a new technology, specific application to the data centre and AI environment represents a nascent market set for strong growth in the coming years. Motivair has years of experience in cooling the world’s fastest supercomputers with liquid cooling solutions. In recent quarters, the company has been tracking a strong double-digit growth trajectory, which is expected to continue as it pivots to provide end-to-end liquid cooling solutions to several of the largest data centre and AI customers.

Peter Herweck, CEO of Schneider Electric, comments, “The acquisition of Motivair represents an important step, furthering our world leading position across the data centre value chain. The unique liquid cooling portfolio of Motivair complements our value proposition in data centre cooling and further strengthens our prominent position in data centre build out, from grid to chip and from chip to chiller.”

Rich Whitmore, President & CEO of Motivair Corporation - who will continue to run the Motivair business out of Buffalo after the closing of the transaction - adds, “Schneider Electric shares our core values and commitment to innovation, sustainability and excellence. Joining forces with Schneider will enable us to further scale our operations and invest in new technologies that will drive our mission forward and solidify our position as an industry leader. We are thrilled to embark on this exciting journey together."

Under the terms of the transaction, Schneider Electric will acquire an initial 75% controlling interest in the equity of Motivair for an all-cash consideration of $850 million (£652m), which includes the value of a tax step-up, and values Motivair at a mid-single digit multiple of projected FY2025 revenue.

The transaction is subject to customary closing conditions, including the receipt of required regulatory approvals, and is expected to close in the coming quarters. On completion, Motivair would be reported within the Energy Management business of Schneider Electric. The Group expects to acquire the remaining 25% of non-controlling interests in 2028.

For more from Schneider Electric, click here.

Simon Rowley - 18 October 2024

Innovations in Data Center Power and Cooling Solutions

News

Sustainable Infrastructure: Building Resilient, Low-Carbon Projects

Schneider Electric announces circular economy UPS offer

Schneider Electric has announced the results of an industry-first, circular economy initiative for its range of APC Smart-UPS uninterruptible power supplies (UPS).

First trialled in France in 2024 via a pioneering reduce, reuse and recycle programme, delivered in partnership with distributor Ingram Micro, Schneider Electric sought to increase the sustainability and circularity of its industrialised single-phase UPS solutions, while meeting customers’ demands for sustainable, responsible systems.

The new solutions enable Schneider Electric’s French partners to address the competitive and fast-growing market for circular IT equipment - helping customers to reduce CO2 emissions associated with their critical systems, and with zero impact on the UPS’ operational performance, resiliency, or energy efficiency.

With several high-profile French customers now utilising Schneider Electric’s circular UPS, including CGR Cinemas – one of Frances’ most notable leaders in the film industry – circular economy projects will also be extended to support partners and customers in key countries across Europe, including the UK and Ireland, Italy, Spain, Belgium, Netherlands and Germany (DACH).

Further, with take-back services delivered with Schneider Electric's partner ecosystem in France, coupled with replacement, recycling and rigorous testing processes via Schneider Electric’s local repair centre, the new solutions form part of a complete circular economy offer to serve the French channel and end-user markets. They allow customers to utilise circular, responsible power protection products with the same level of quality and warranty as Schneider Electric standard UPS, while being less CO² emissive.

“When we first set out to establish our circular UPS offer, our ambition was to ensure that there was no compromise on the efficiency, resilience and the sustainability of our industrial processes, and to create sustainable solutions that deliver the same level of quality and reliability our customers expect,” says Geoffrey Richard, Schneider Electric’s Circular Economy Director, France. “Through these new UPS’, our partners can meet customer demands for sustainable solutions safe in the knowledge that they are making a significant contribution to environmental sustainability, and that their customers will benefit from the same warranty as standard Schneider Electric Smart-UPS models.”

“As one of the largest distributors in Europe, Ingram Micro is on a mission to help our partners and their customers run better, grow faster, and become more mindful of the impacts their actions have on people and our planet,” adds Sandrine Vigor, Sustainability Manager at Ingram Micro, France. “We’re delighted to have partnered with Schneider Electric to bring this industry-first initiative to life, and one which aligns so closely with the values of our IngramMicroESG programme perfectly - supporting our ambitions to help businesses become more sustainable, globally.”

Serving the market for second life IT

Research published by Canalys in 2024 found that 50% of partners expect to generate revenue from sustainability solutions this year, and that a further 92% of customers are seeking guidance from partners around sustainable product procurement processes, including circular IT systems.

Schneider Electric’s new circular UPS offer not only support partners’ ambitions to capture growth opportunities associated with sustainable products but enables them to act as trusted partner for take-back, recycle and replacement services, while meeting local environmental and regulatory requirements such as the European Energy Efficiency Directive (EED), Paris agreement, and the United Nations (UN) climate objectives.

According to the Circularity Gap report 2023, a transition to a global circular economy will allow us to fulfil people's needs with only 70% of the materials we now extract and use – moving human activity back within the safe limits of the planet. Schneider Electric’s own research showed that products from the circular economy can reduce CO2 emissions by an average of 35% compared to first-time manufacturing – a transformation which involves profound supply chain changes to recover products and equipment for reconditioning, repair or remove spare parts to repair others.

From an environmental standpoint, Schneider Electric’s new circular UPS offer requires key processes which include taking back the end-of-life UPS, detailed diagnosis and testing, dismantling and refurbishment of all single critical parts and end of use components such as batteries, switches and LEDs, reassembly, and rigorous testing – all prior to repackaging and resale, with the same alignment on applicable standards, quality and warranty as a brand-new UPS.

Further, as the UPS solutions require less primary extraction of raw materials, and a reduction of potentially harsh or hazardous substances, customers are also more resilient against fluctuations in the pricing and availability of raw materials, and importantly, can ensure that embodied CO² or Scope 3 emissions associated with the production process are far lower than that of a standard system.

Delivering circular solution for CGR Group

One high-profile adopter of Schneider Electric’s circular UPS solutions is The CGR Cinemas group, which operates 713 movie theatres across France. CGR is well-known as a major player in the French film industry, leading for several decades and is the second largest operator of cinemas in the region.

A key part of its strategy is to create places where emotions, exchanges and experiences are lived and reinvented without respite, and it has developed a park of 45 premium ICE rooms in its cinemas, including the deployment of 4K laser projectors within its theatres and new comfort rooms for an ever more qualitative experience.

Protecting its critical systems from power failures is vital to the customer experience, so it chose Schneider Electric’s new circular UPS offer not only for the quality of its innovative products, but because the company’s commitments to creating environmentally friendly technologies met CGR’s requirements for energy efficiency and sustainability. By using Schneider Electric’s circular Smart-UPS, CGR Cinemas will save 11T600 (11,600 tonnes) of CO² emissions, while safeguarding their critical equipment.

Michael Cron, Logistics and Purchasing Director, CGR Group, notes, "Schneider Electric’s choice was natural, as their commitment to environmentally friendly products is in perfect harmony with our values of sustainability. Their innovative and eco-friendly approach, while meeting our high-performance requirements, is fully in line with our ambitions for environmental responsibility and efficiency. This choice, both technical and economic, can only be realised and sustained through common interaction and collaboration."

For more from Schneider Electric, click here.

Simon Rowley - 17 October 2024

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Oslo data centre implements advanced biofuel

STACK Infrastructure has announced it has successfully implemented the use of the advanced biofuel HVO100 (Hydrotreated Vegetable Oil) as a standby power source for a new data centre on its OSL04 campus in Holtskogen (Oslo), Norway.

STACK is committed to reducing, and eventually eliminating, Scope 1 emissions from its data centres. After rigorous testing, HVO100 – the purest form of HVO – is now being utilised in lieu of fossil fuel-based diesel. Advanced biofuels such as HVO are typically made from vegetable oil or used cooking oil and generally produce fewer emissions than regular fuel.

Research suggests 1,000l of HVO releases 195kg of carbon dioxide, compared to 3,600kg for the same amount of regular diesel. HVO100 has also been shown to produce approximately 33% lower levels of fine particles, 9% fewer nitrogen oxides, 30% fewer hydrocarbons, 24% lower carbon monoxide, and lower levels of polyaromatic hydrocarbons than traditional diese. Lower smoke and soot emissions were also recorded when using HVO.

“STACK understands that sustainability is a business imperative that shapes how we design, construct and operate critical infrastructure in an increasingly digital world,” says John Eland, CEO, STACK EMEA. “To address our Scope 2 emissions, we already utilise 100% renewable energy across our global data centre portfolio. Implementing HVO100 aligns with our commitment to reducing our Scope 1 emissions, marking a significant step toward a greener future.”

“We are proud to be pioneering green initiatives in Norway,” adds Geir Vistung, Manager of STACK’s OSL04 Campus. “Our heat reuse program in Oslo is award-winning, we harvest rainwater to support our cooling systems at several of our data centre campuses, and the use of HVO100 is yet another example of industry-leading innovation.”

In addition to this latest facility on the OSL04 campus, two more STACK data centres became operational this year in Oslo, increasing STACK's footprint in Norway by another 18MW. STACK’s continued expansion in the Nordics also includes a 72MW campus under development in Copenhagen and an 18MW campus under development in Stockholm. STACK’s EMEA presence spans additional key markets including Milan, Geneva, Zurich and Frankfurt, with an operational and planned portfolio amounting to more than 1GW across the region.

Carly Weller - 15 October 2024

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

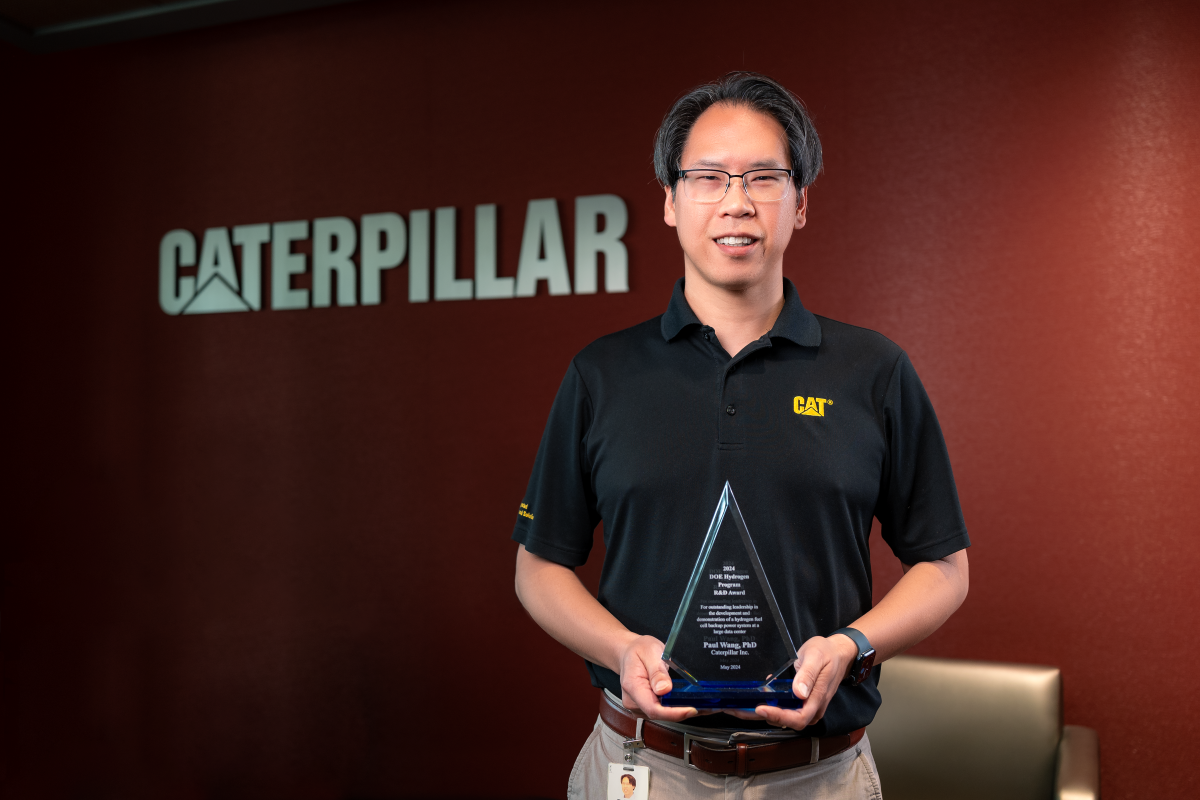

Award for Caterpillar data centre power solution

Caterpillar has announced that its collaboration with Microsoft and Ballard Power Systems on a data centre power solution using a large-format hydrogen fuel cell earned the top honour in the 'Systems Development and Integration' category at the US Department of Energy’s (DOE) Hydrogen Program 2024 Annual Merit Review Awards.

Presented at the 2024 Annual Merit Review and Peer Evaluation Meeting, the awards recognise contributions to overall programme efforts and highlight research, development, and demonstration achievements in specific disciplines.

The award was accepted by Paul Wang, Ph.D. (pictured above), Senior Engineering Project Team Lead for Caterpillar, who represented a team of more than 50 engineers demonstrating the viability of large-format hydrogen fuel cells for supplying reliable backup power for data centres. The project simulated a 48-hour backup power event at Microsoft's data centre in Cheyenne, Wyoming, using two Cat Power Grid Stabilisation (PGS) 1260 battery energy storage systems and a 1.5 MW hydrogen fuel cell.

The demonstration provided valuable insights into the capabilities of fuel cell systems to power multi-megawatt data centres, ensuring uninterrupted power supply to meet 99.999% uptime requirements.

Caterpillar led the project, providing overall system integration, power electronics, and microgrid controls that form the central structure of the hydrogen power solution. Microsoft hosted the demonstration project, while Ballard supplied an advanced hydrogen fuel cell module.

Backed by the National Renewable Energy Laboratory (NREL), the demonstration is supported and partially funded by the DOE’s Hydrogen and Fuel Cell Technologies Office under the H2@Scale initiative.

“This award from the DOE validates how Caterpillar's advanced technologies, industry expertise and collaborative approach are helping customers meet their climate-related objectives,” says Jaime Mineart, Senior Vice President of Caterpillar Electric Power.

Caterpillar, along with its global Cat dealer network, helps customers meet uptime commitments at thousands of data centre facilities worldwide, offering highly responsive power solutions and expertise in specification, installation, commissioning and service.

Caterpillar’s hydrogen-fuel power technologies also include a range of commercially available generator sets configured to operate on natural gas blended with up to 25% hydrogen by volume. The company is also leading a project with Minnesota-based District Energy St. Paul to demonstrate a hydrogen-fuelled combined heat and power (CHP) system.

Beyond the company’s hydrogen power solutions, Caterpillar continues to invest in new products, technologies and services to help customers achieve their climate-related objectives. These include Distributed Energy Resource Management System (DERMS) software solutions for monitoring, managing, and monetising on-site energy assets; a full hybrid energy solutions technology suite; Cat CHP systems and combined cooling, heat and power (CCHP) systems; support for hydrotreated vegetable oil (HVO), biodiesel, and blended fuel products; and solutions expertise in landfill gas, biogas and other waste-to-energy applications.

For more from Caterpillar, click here.

Simon Rowley - 11 October 2024

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Vertiv introduces EnergyCore battery cabinets

Designed to meeting the urgent need for solutions supporting high-density computing in increasingly crowded data centre facilities, Vertiv, a global provider of critical digital infrastructure and continuity solutions, has introduced Vertiv EnergyCore battery cabinets.

Factory assembled with LFP (Lithium-Iron-Phosphate) battery modules and Vertiv’s internally-powered battery management system, Vertiv EnergyCore cabinets are available globally and are qualified for use with most current and legacy three-phase Vertiv uninterruptible power supply (UPS) systems, including the recently launched Vertiv Trinergy.

Vertiv EnergyCore cabinets are optimised for five minutes end-of-life runtime at 263kWb per each compact, 24” wide (600mm) cabinet, and operate across a wide temperature range, making them suitable for high-density environments. Lithium batteries are more compact and lighter than VRLA alternatives, allowing users to deploy fewer battery cabinets in most applications. An internal two-hole lug eliminates the need for a conduit box, and the cabinets require no on-site external control wiring, reducing deployment time and cost compared to traditional on-site assembly. The cabinets are equipped with Vertiv’s intuitive interactive touch screen HMI display to provide visibility and control of the cabinet, operating system, and the installed batteries.

The integrated battery management system is powered by the Vertiv EnergyCore batteries, removing the requirement for an external power source and simplifying installation. It provides lifetime onboard data storage, tracking performance over battery charge-discharge cycles, service events, and enabling accurate state-of-health reports that can be used for warranty support and predictive analytics. Remote battery monitoring is available via Vertiv Alber Battery Xplorer Enterprise.

“The proliferation of AI and other high-performance computing applications is putting a premium on the ability to deliver more power in smaller, hotter spaces,” says Milind Paranjape, Vice President of Energy Storage at Vertiv. “With the Vertiv EnergyCore battery cabinets, Vertiv is delivering exactly what its customers and the industry need – compact, high power energy storage capable of operating safely and optimally. Simply put, these battery cabinets are designed for the emerging mission-critical needs of high-density computing environments.”

The modular design of Vertiv Trinergy allows each UPS core to be paired with dedicated Vertiv EnergyCore battery cabinets in a distributed architecture, enabling uninterrupted service for critical applications. Due to the power density of the Vertiv EnergyCore design, only two lithium-ion battery cabinets are needed to support each 500kW Trinergy UPS core, versus the three cabinets that are required by most suppliers.

Vertiv EnergyCore is UL 1973 listed and has been successfully tested for compliance to UL 9540A standard for protection against thermal runaway fire propagation in battery energy storage systems, which, according to NFPA 855 ESS installation standards, means the three feet (92cm) spacing requirements between racks can be waived by the Authorities Having Jurisdiction. This can save space and speed deployment.

For more from Vertiv, click here.

Simon Rowley - 9 October 2024

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

Vertiv expands single-phase UPS portfolio

Vertiv, a global provider of critical digital infrastructure and continuity solutions, has introduced 1kVA to 3kVA capacities of the Vertiv Liebert GXE, an online double conversion, single-phase uninterruptible power supply (UPS) for 230V applications designed to support critical applications deployed at the network edge.

With the addition of the new models, the Liebert GXE family is now available in a complete 1kVA to 10kVA capacities range and is ready for immediate shipping from stock within Europe, the Middle East, and Africa (EMEA), Asia, and LATAM warehouses.

The Liebert GXE 1-3KVA UPS is available in a compact tower-only model or in a flexible rack/tower convertible design and delivers high efficiencies of up to 91% in online mode and up to 96% in ECO mode. It features a battery management system that supports prolonged battery lifespan and minimises the need for replacements. Additionally, its output power factor of 0.9 allows for more active loads to be connected within a given space, while its online double conversion technology protects equipment from power disturbances.

The Liebert GXE rack/tower models provide scalable runtime for applications that need extended backup during AC mains outages, achievable by adding up to four external battery cabinets, and a fast recharge time thanks to its powerful 6 Amp internal charger. The hot-swappable VRLA batteries are user-replaceable without needing skilled personnel or powering down the loads, ensuring smooth operation and reduced maintenance costs.

In addition, the Liebert GXE features an intuitive LCD display that offers insights into the UPS status, facilitating straightforward installation and operation. This unit provides remote monitoring capabilities, enabling convenient access to IT infrastructure via the optional Vertiv Liebert Intellislot Unity Communications card, along with a complimentary download of the Vertiv Power Insight software.

Finally, Vertiv offers a wide service offering including limited warranty extensions, power emergency packages, and other options, depending on the country and UPS model.

“The rapid advancement of digitalisation, including AI and the growing reliance on data services, makes power continuity increasingly crucial for all businesses, even at the network edge," states Andrea Ferro, Vice President for Channel, IT and Edge Applications at Vertiv in EMEA. "The Liebert GXE provides energy-efficient and reliable power protection, helping small and medium businesses sustain operations in these distributed applications."

The UPS is available with a comprehensive range of limited warranty extensions and service programmes designed for single-phase UPS systems. These service programmes are available in select countries; visit Vertiv's website for specific availability or contact your local representative.

EMEA resellers in participating countries can earn points through the Vertiv Incentive Programme (VIP) for various activities, including sales of the Liebert GXE and other products in Vertiv’s IT channel portfolio. This programme allows partners to win rewards, without any need for reporting. Bonus points are added to the Vertiv Partner Portal monthly, and partners simply need to log in to redeem them.

For more from Vertiv, click here.

Simon Rowley - 24 July 2024

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

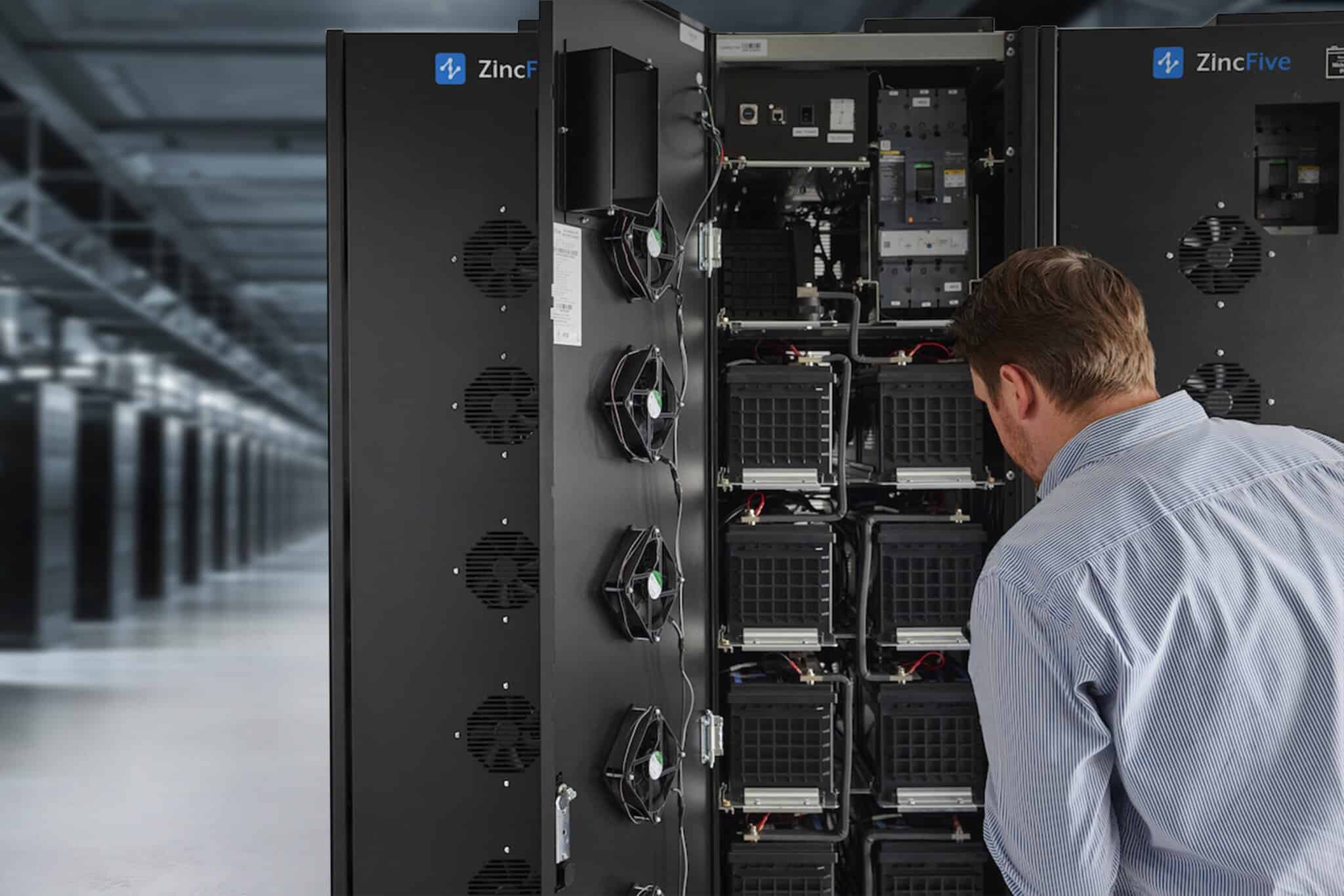

Vertiv and ZincFive collaborate to deliver safe energy storage

Vertiv, a global provider of critical digital infrastructure and continuity solutions, and ZincFive, a provider of nickel-zinc (NiZn) battery-based products for immediate power applications, today announced that Vertiv will add the ZincFive BC Series uninterruptible power supply (UPS) Battery Cabinets to its portfolio of battery systems available for data centre backup power.

The safe and recyclable nickel-zinc batteries are compatible with select large and medium Vertiv UPS systems, including the recently launched Vertiv Trinergy, as a source of backup energy storage, complementing the company’s commitment to enable customers to minimise the environmental footprint of their data centre sites. The ZincFive BC Series UPS Battery Cabinets are now available from Vertiv in the EMEA region.

ZincFive’s BC Series UPS Battery Cabinets are reportedly the first nickel-zinc battery energy storage solution with backward and forward compatibility with megawatt class UPS. The BC Series offers the smallest footprint in the industry compared to VRLA and Lithium-Ion, and minimal maintenance requirements. The NiZn chemistry provides reliable operation, with the battery strings remaining conductive, even with weak or depleted cells. In addition, according to a study performed by Boundless Impact and commissioned by ZincFive, ZincFive’s NiZn batteries have a significantly lower end-to-end environmental impact than lead-acid and lithium batteries, as validated by expert third-party analysis.

ZincFive's CEO and Co-Founder, Tim Hysell, comments, "Our relentless commitment to innovation shines through our powerful, safe, and reliable nickel-zinc battery technology. The BC Series represents an ideal solution to meet the evolving demands of data centres, both today and in the future. Furthermore, the importance of sustainability in data centre backup battery systems is on the rise, aligning perfectly with the shared values of ZincFive, our partners, and our customers. We are dedicated to minimising carbon emissions and operational expenses without compromising on safety or performance."

Milind Paranjape, Vertiv's Senior Director of Energy Storage, adds, "Vertiv and ZincFive want to enable reliable and efficiently operated data centres around the world, providing greater access to data, with less waste and greater energy efficiency. Vertiv has already deployed the ZincFive product at several sites for major data centre companies.”

Milind also said the technology is an excellent solution for customers faced with challenges with local Authorities Having Jurisdiction (AHJs) regarding National Fire Protection Association (NFPA) standards and the International Fire Code (IFC).

For more from Vertiv, click here.

Simon Rowley - 16 July 2024

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Vertiv unveils next-generation Trinergy UPS

As global electricity demand from data centres is expected to double by 2026 – largely driven by computing and cooling requirements from AI and HPC (high-performance computing) – it is crucial to have a robust backup power solution to provide continuous availability of the GPUs and CPUs that run AI compute.

To address these challenges, Vertiv, a global provider of critical digital infrastructure and continuity solutions, today introduced Vertiv Trinergy, an uninterruptible power supply (UPS) engineered to handle the fluctuating load demands of data centres, and Vertiv PowerNexus, an integrated solution that provides space-saving close coupling of the UPS and system switchgear. Both solutions are available globally, with the Vertiv Trinergy UPS being available in 1500, 2000, and 2500 kVA capacities.

Vertiv calculates that Vertiv Trinergy exceeds Tier IV data centre power chain expected availability, with 99.9999998% projected uptime compared to 99.9994% – a difference between 30 seconds of downtime in 10 years for Vertiv Trinergy, compared to eight hours in 10 years as expected for the Tier IV data centre power chain. The system boosts resilience with extended backup time configurations and its innovative self-isolating core design, with modular architecture that features 500kW physically segregated cores. Each core includes the components of an online UPS: inverter, rectifier, booster/charger, and dedicated, segregated controls, allowing each core to operate independently, providing reliable uninterrupted power delivery even during maintenance.

"High-capacity power in a highly reliable system design is critical for data-intensive AI and HPC applications," states Kyle Keeper, SVP of Power Management Global Business unit at Vertiv. "Leveraging over 40 years of innovation, Vertiv Trinergy UPS offers the resilience essential for operations to become future-ready and to support AI loads. It delivers the flexibility required to adapt to various AI applications and is designed to integrate seamlessly with different prime and backup power sources, lithium-ion and nickel-zinc batteries, and alternative distributed energy sources, including fuel cells and long duration batteries (BESS)."

Vertiv Trinergy scales the concept of modularity up to all levels of the UPS architecture. Building blocks can be combined to fit different deployment types, achieving considerable space savings with its compact footprint. It streamlines power distribution through a single connection point, cutting down the necessity for numerous cables, flanges, bus ducts, and switchgear connections for UPS outputs.

Vertiv Trinergy footprint is further maximised when integrated with Vertiv PowerBoard Switchgear as part of the new Vertiv PowerNexus solution, close coupled into a single block connected by internal busbars. This integration also reduces cabling materials, installation time, and installation labour costs. The Vertiv PowerNexus is also available integrated onsite, as a power skid or integrated into an enclosure, providing flexibility to meet specific site needs. Vertiv PowerNexus integration is completed at the factory, saving installation time at the site. The integrated Vertiv EPMS (energy and power monitoring system) with onboard energy monitoring makes the system safer, more reliable and more operable out of the box by increasing visibility and reducing the number of interconnections.

The UPS may be supported by the Vertiv project and lifecycle services portfolio, which includes a new suite of data enabled services, including Vertiv LIFE advanced incident management and condition-based maintenance analytics and health scores.

Vertiv Trinergy delivers an outstanding double conversion efficiency of up to 97.1%, which further increases up to 99% with the Dynamic Online mode, reducing operating costs and energy dissipation. This significantly minimises the consumption of the cooling system, enabling an overall TCO reduction and shorter payback time.

The UPS can provide additional energy saving, as well as cost saving and revenue generation, by leveraging the Dynamic Grid Support feature, which allows the UPS to participate in demand management and other grid services, where available.

With its improved continuous duty booster operation, the UPS is capable of running from a DC source, even at full load, for an indefinite amount of time. The UPS is also compatible with Vertiv DynaFlex Battery Energy Storage System (BESS), which can leverage alternative energy sources for backup or primary power as part of a bring your own power (BYOP) strategy. The replacement of diesel generators as backup power can contribute to a lower mean time to repair (MTTR), and contributes to decarbonisation.

For more from Vertiv, click here.

Simon Rowley - 9 July 2024

Cooling

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

News

Iceotope launches state-of-the art liquid cooling lab

Iceotope Technologies, a global provider of precision liquid cooling technology, has announced the launch of Iceotope Labs, the first of its state-of-the-art liquid cooling lab facilities in Sheffield.

Designed to revolutionise high-density data centre research and testing capabilities for customers seeking to deploy liquid cooling solutions, Iceotope believes that its Iceotope Labs will set new standards as the industry's most advanced liquid-cooled data centre test environment available today.

Amid the exponential growth of AI and machine learning, liquid cooling is rapidly becoming an enabling technology for AI workloads. As operators evolve their data centre facilities to meet this market demand, validating liquid cooling technology is key to future-proofing infrastructure decisions.

By leveraging advanced monitoring capabilities, data analysis tools, and a specialist team of test engineers, Iceotope Labs will provide quantitative data and a state-of-the-art research and development (R&D) environment to demonstrate the benefits of liquid cooling to customers and partners seeking to utilise the latest advancements in high-density infrastructure and GPU-powered computing. Examples of recent research conducted by Iceotope Labs includes groundbreaking testing for next-gen chip level cooling at both 1500W and 1000W. These tests demonstrated precision liquid cooling’s ability to meet the thermal demands of future computing architectures needed for AI compute.

Working in partnership with Efficiency IT, a UK specialist in data centres, IT and critical communications environments, the first of Iceotope’s bespoke labs showcases the adaptability and flexibility of leveraging liquid cooling in a host of data centre settings including HPC, supercomputing and edge environments. The fully functional, small-scale liquid cooled data centre includes two temperature-controlled test rooms and dedicated space for thermal, mechanical and electronic testing for everything from next generation CPUs and GPUs to racks and manifolds.

Iceotope Labs also features a facility water system (FWS) loop, a technology cooling system (TCS) loop with heat exchangers, as well as an outside dry cooler – demonstrating key technologies for a complete liquid cooled facility. The two flexible, secondary loops are independent of each other and have a large temperature band to stress-test the efficiency and resiliency of a customers' IT equipment if and when required. Additionally, the flexible test space considers all ASHRAE guidelines and best practices to ensure optimal conditions for a range of test setups for enhanced control and monitoring all while maximising efficiency and safety.

"We are investing in our research and innovation capabilities to offer customers an unparalleled opportunity," says David Craig, CEO of Iceotope. “Iceotope Labs not only serves as a blueprint for what a liquid cooled data centre should be, but is also a collaborative hub for clients to explore liquid cooling solutions without the need for their own lab space. It's a transformative offering within the data centre industry."

David continues, “We’d like to thank Efficiency IT for its role in bringing Iceotope Labs to fruition. Its design expertise has empowered us with the flexibility needed to create a cutting-edge facility that exceeds industry standards."

“With new advancements in GPU, CPU and AI workloads having a transformative impact on both data centre design and cooling architectures, it’s clear to see that liquid cooling will play a significant role in improving the resiliency, energy and environmental impact of data centres,” adds Nick Ewing, MD, EfficiencyIT. “We’re delighted to have supported Iceotope throughout the design, development and installation of its industry-first Iceotope Lab, and look forward to building on our collaboration as together, we develop a new customer roadmap for high-density, liquid-cooled data centre solutions.”

Located at Iceotope's global headquarters in Sheffield, UK, Iceotope Labs further expands the location as a hub for technology innovation and enables Iceotope to continue to deliver the highest level of customer experience.

For more from Iceotope, click here.

Simon Rowley - 9 July 2024

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173