WB Power Services to transform power reliability across the UK

Author: Beatrice

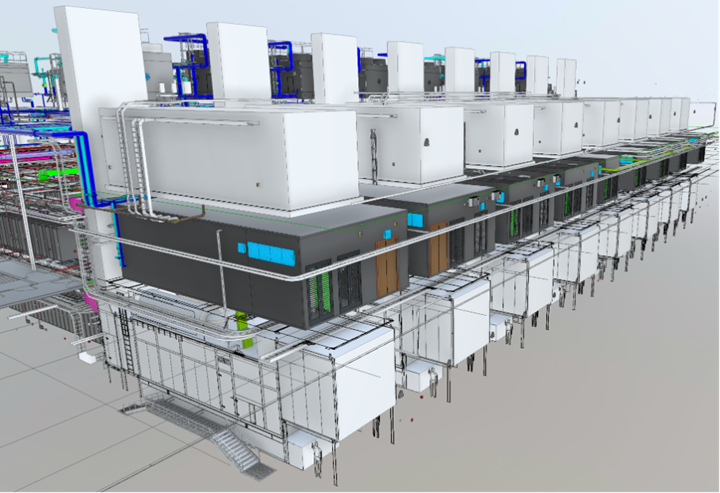

WB Power Services has announced the launch of a new plug and play standby power facility to support the growing needs of the data centre industry.

Designed by WB Power Services at its own production facility, the data centre e-Pod is a modular, site bespoke package, providing a generating set, fuel system, mains transformer, switch gear and UPS. It has the advantage of being containerised and has a unique site infrastructure which can be tailored to specific brief and project requirements.

The package can be tweaked according to the client requirements and design brief, incorporating preferred products as per any pre-determined specs. Truly bespoke, it promotes reduced lead times with the design, procurement, packaging, installation, and commissioning implemented under just one expert supplier.

WB Power Services Managing Director, Andrew Wilmott, says, “We have been able to draw on our insights in the data centre sector to create a truly industry leading backup power facility that is a real game changer. We know that no solution is perfect for every project, so using our design capabilities and project management expertise, we have developed a plug and play solution that can be adjusted according to individual requirements.

“Using Kohler generating sets and a fuel system that has 48-hour capability, we have added a power pod that includes tripping batteries and USP that can manage internal essential services. Add to that health and safety requirements, a gantry system and commissioning, we will also maintain and service each installation as required. We are focused on building our data centre offer this year, and the launch of the Power-E cements out commitment to the sector.”

Customising the standby power solution

The WB Power Services in-house design team can facilitate specific customer needs and requirements. From project conception, the team will work in partnership with the client design team, offering full electrical and mechanical design support to ensure each requirement is catered for.

Factory Acceptance Testing

Each element of the equipment will be fully tested prior to leaving the manufacturer’s plant, with pre-commissioning taking place prior to despatch from WB Power Services’ packaging facility. Full FAT testing of each package element of the three pods is offered, with the scope and duration tailored to meet specific client specification.

Site management and installation

WB Power Services will undertake the installation of Preedcrete busbar within the LV POD during manufacture and complete the interconnecting elements once on-site. The busbar would be taken to the end of the pod and enclosed in a suitable rated enclosure external to the main pod ready for ongoing connection to the building. This is to allow the cable/busbar running into the building to be installed without entry into the main pod, as previously done on phase one.

The cooling requirements are not yet fully known, however, the company has included a budget price for both CRAC units and associated pipe work to end wall of the pod to connect into the site wide pipework by the GC. The fire alarm and suppression system and fire alarm will be designed to match the site wide system and will be taken to marshalling points within the pod for connection to BMS outstations, and security system. All are excluded from pricing currently; WB Power Services would liaise with the respective specialist to ensure the pod meets their requirements and the pods would be available WB Power Services’ works for them to install their equipment.

Commissioning

During the construction and installation phases, the WB Power Services project delivery team will ensure the finalising of the commissioning plan and programme. Once both the mechanical and electrical installations have been completed, the commission and test aspects of the installation are carried out. This will culminate in a full site acceptance test (SAT), including load testing fully coordinated with all other services providers working on the project.

Through life maintenance

With six fully operational depots and over 80 field-based engineers located across the UK, WB Power Services is uniquely placed to offer a full and comprehensive preventative maintenance, plus four-hour emergency response to any client site. The WB e-Pod packages contain a wide range of electrical equipment provided by long-standing specialist partners to provide all necessary specialist maintenance and emergency support on unique products.