Innovations in Data Center Power and Cooling Solutions

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

Centiel launches rapid deployment UPS hire service

Centiel's award-winning UPS innovations are now available to hire on a short or longer-term basis for data centres needing instant power protection during refurbishment, or other facilities such as hospitals which require an immediate, temporary uninterruptible power supply.

Andrew Skelton, Operations Director at Centiel, explains, “We offer flexible, rapid deployment of our industry leading UPS solutions from our standalone and modular ranges from 10kW to 1.5MW. We also have containerised modular UPS solutions for larger projects between 50kW and 1.5MW. Our containerised solutions hire includes electrical installation, integral lighting, fire detection and suppression, cooling, batteries and 24/7/365 support with guaranteed site attendance, making it suitable as a full ‘plug and play’ emergency option or for facilities needing to back up their existing UPS while refurbishment or other works take place.

“Our UPS hire solution can be arranged to suit specific needs at very short notice. Subject to availability, we currently have two 600kW and one 300kW containerised, flexible UPS solutions ready to deploy within 48 hours and we are currently adding to the fleet. We can also parallel them together for sites requiring up to 1.5MW of backup power. The containers can be delivered onto suitably rated hard standing areas to suit disaster recovery situations or planned shutdowns.

“The UPS's arrive fully tested with batteries already charged. We simply deliver the bespoke containerised UPS solution into position, install the top row of batteries and connect the AC input and output cabling via Powerlock connections, so the system is typically up and running within six hours of delivery.”

Routine maintenance is covered by the hire charge for extended hire periods and Centiel’s UPS can remain on site for as long as the facility needs critical power protection. Hiring a UPS may be a tax efficient way to solve an organisation’s short term power protection problems as a purchase comes out of Capital Expenditure (CAPEX), whilst a rental can be set against Operational Expenditure (OPEX).

Centiel’s UPS hire service is available for its standalone UPS PremiumTower and also its three-phase, modular UPS CumulusPower which offers '9 nines' (99.9999999%) availability to effectively eliminate system downtime; class leading 97.1% on-line efficiency to minimise running costs and true 'hot swap' modules to eliminate human error in operation.

Andrew continues, “Our fast deployment UPS's, including our containerised solutions, are ready to go. They are an ideal temporary solution for data centres, hospitals or other facilities needing to provide critical power at short notice or for an economical option to support more planned projects.”

Centiel now protects critical loads for data centres and comms rooms in over 100 countries across five continents.

For more from Centiel, click here.

Simon Rowley - 23 April 2024

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

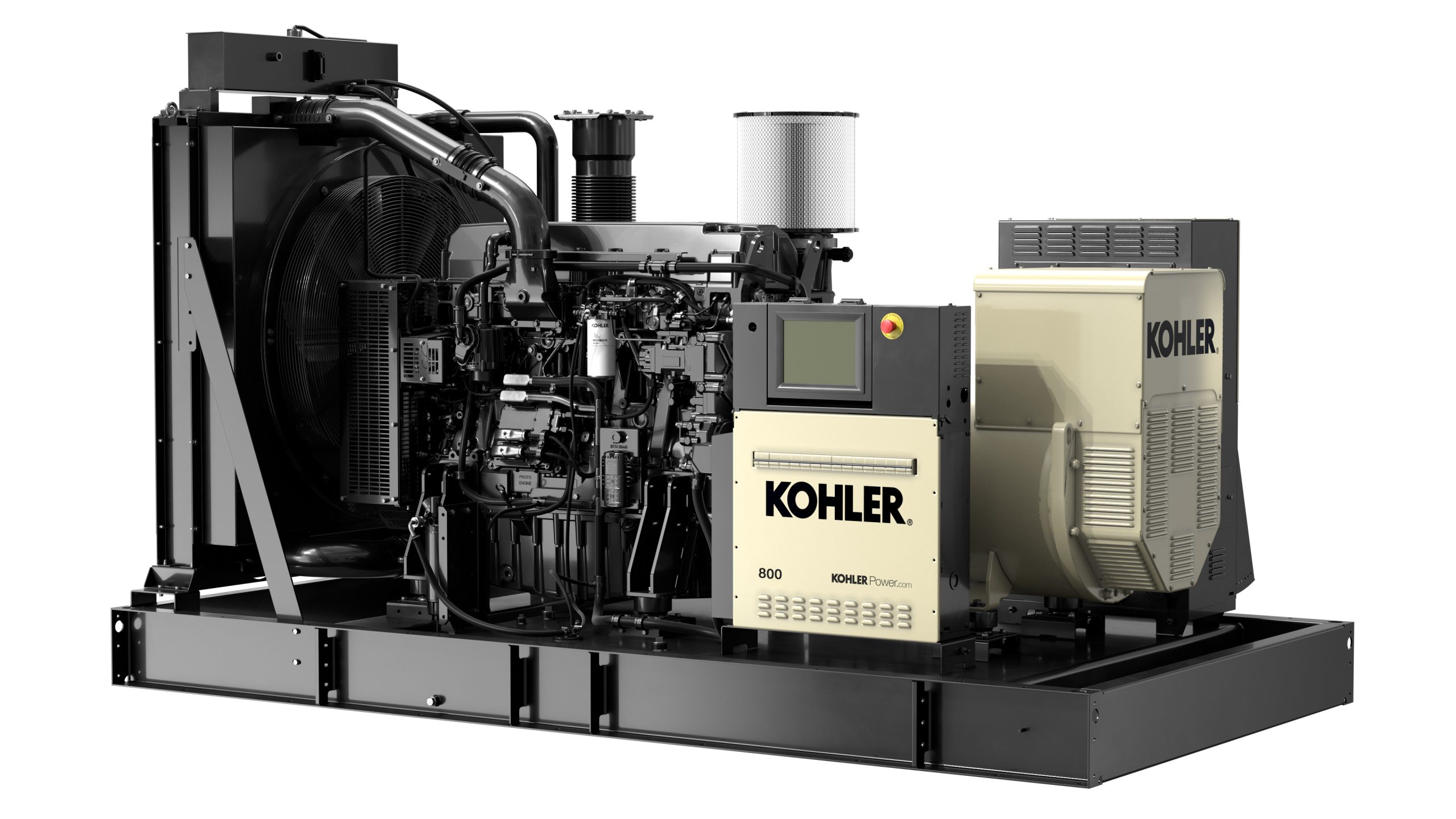

Kohler launches new KD Series industrial generator

Kohler Power Systems, part of Kohler Energy, has expanded its KD Series line of industrial generators with a new model, KD800, designed for 50hz markets. This generator features a new advanced engine (KD18L06) that can also run on Hydrotreated Vegetable Oil (HVO) as a renewable fuel source.

This new model joins a proven series of gensets that continues to provide the highest power density and best fuel consumption at more nodes than competitors between 800-4500 kVa, offering cost savings to users. The new KD unit is designed to power mission-critical applications, including airports, hospitals, and healthcare facilities, water treatment plants and mid-sized data centres.

The KD800 joins Kohler’s industrial generators that are engineered to use HVO fuel. HVO provides a more sustainable alternative to conventional diesel and biofuels. No adaptation is needed and both HVO and diesel can be mixed together. HVO is also highly stable, with no sensitivity to oxidation, so it can be stored long-term. It enables to offset carbon emission by up to 90% by using renewable waste products.

Kohler’s KD Series is designed to deliver extreme durability and ultimate reliability in a variety of emergency and prime applications. KD Series generators are engineered to last, with better fuel economy and a small footprint. When paired with Kohler’s global sales and support network, the KD Series line-up provides an innovation that secures customers’ critical operations. And when service is needed, Kohler has a global dealer and distribution infrastructure consisting of more than 800 facilities offering 24/7 parts availability.

For additional details about the Kohler KD Series range, visit its product catalogue by clicking here.

For more from Kohler, click here.

Simon Rowley - 23 April 2024

Innovations in Data Center Power and Cooling Solutions

News

Don’t compromise on power protection

By David Bond, Chairman, Centiel UK

When we are ill, we consult a doctor, a trusted expert in the human body, to diagnose and appropriately treat the problem. They will also advise on how to best prevent a recurrence of the problem. Hopefully, we don’t listen to “old wives tales” that guarantee an immediate cure.

The same common sense applies with the diagnosis, help and advice for critical power protection. Nobody would knowingly purchase an inferior UPS, but how would they know a good UPS from an inferior one? If you’re not a UPS expert, it’s easy to fall for sales talk and marketing speak, but just like a doctor won’t try and ‘sell’ you unnecessary medication, real UPS experts will act as trusted advisors and will only act in their customers’ best interest. No sales 'spin', just facts and sound advice.

While Centiel’s team of UPS experts don’t swear an hypocritic oath like a doctor does, every Centiel employee signs up to a set of core values which keeps the best interests of customers at the heart of everything they do, namely:

We always behave with integrity

We are honest and open in our business transactions

We treat our customers, suppliers and each other with respect

We constantly strive to improve our customer service

We never compromise on health, safety or environmental matters

Finding the best way to protect critical power is a complex topic. Therefore, Centiel’s expert team act as trusted advisors to all customers, including data centres, hospitals and all IT facilities, to ensure they always have the optimal UPS solution, whilst reducing their Total Cost of Ownership (TCO) and maximising their system availability.

Centiel’s engineers and UPS solutions experts and are not required to 'sell' UPS. Instead they establish long term relationships by offering their wealth of experience and expertise. By taking time to understand the challenges faced, they always provide the best advice in relation to solutions based on best practice.

It's this long-term vision and close relationships with Centiel’s clients which led to the development of its industry-leading UPS solutions. For example, Centiel recently launched StratusPower, which shares all the benefits of the award-winning three phase, true modular UPS CumulusPower - including '9 nines' (99.9999999%) availability to effectively eliminate system downtime; class leading 97.6% online efficiency to minimise running costs; true 'hot swap' modules to eliminate human error in operation – but now also includes long-life components to improve sustainability. StratusPower minimises TCO because of its class-leading efficiency and low maintenance costs and it is fully scalable, so is unlikely be outgrown.

Centiel’s experts help organisations around the world understand TCO calculations and provide best recommendations to protect power from day one and into the future. Armed with this information, informed decisions can be made about the most appropriate option to protect critical power, reduce carbon footprint and maintain the highest level of availability.

So just like you would consult a doctor to maintain your optimal health, when it comes to looking at UPS solutions, don’t compromise. Choose experts who will provide best advice to protect your critical power.

To arrange a discussion or for more information, click here.

Isha Jain - 8 November 2023

Data Centre Build News & Insights

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Renewables and Energy: Infrastructure Builds Driving Sustainable Power

Sustainable Infrastructure: Building Resilient, Low-Carbon Projects

Pulsant gains recognition for environmental and sustainability initiatives

Pulsant has seen its commitment to environmental and sustainable working practices receive two key industry certifications in recognition of its focus on environmental and sustainability initiatives across its data centre estate and management systems.

Rating in the top 25% of responding businesses, it received a silver medal from EcoVadis, with particular strengths in the area of its environmental practices. This achievement reflects Pulsant's commitment to environmental stewardship and social responsibility. The company has implemented numerous initiatives to reduce its carbon footprint, minimise waste, and promote ethical business practices, including wellbeing and mental health.

Furthering its sustainability credentials, its energy management system has been awarded the respected ISO 50001 certification, giving independent assurance to its effectiveness in improving its energy performance. As an operator of a variety of UK data centres, it is working towards an overall PUE of 1.3 by 2030, and is on track to surpass the 2023 target of 1.53, following from the success of a number of initiatives such as consolidation project at Maidenhead site, cold aisle containment, cooling and UPS infrastructure upgrades, and temperature optimisation.

Commenting on the news, Helen Munro, Head of Environment and Sustainability at Pulsant, notes, "Sustainability is a key priority at Pulsant. We are committed to continuous improvement across all aspects of our activities, both internally and across our wider supply chain. These certifications highlight that our comprehensive policies and programmes are delivering meaningful results. Credit to the teams across our sites and operations across all parts of the business for making it happen."

As the need for improved environmental management intensifies, Pulsant is focused on further minimising its climate impact, with initiatives already underway, including piloting HVO fuelled generators and evolving cooling technologies.

“We are currently ahead of the annual targets we set to work towards our 2050 net zero targets, but well aware that we need to continue to push to find new opportunities to improve our carbon footprint and environmental impact in the years ahead. We all have a part to play in safeguarding the planet and we are aware of the role our organisation needs to play in that,” concludes Helen.

Isha Jain - 7 November 2023

Innovations in Data Center Power and Cooling Solutions

News

Sustainable Infrastructure: Building Resilient, Low-Carbon Projects

Schneider Electric finalises acquisition of EcoAct

Schneider Electric has announced that it has finalised the acquisition of EcoAct SAS (EcoAct), an international leader in climate consulting and net zero solutions headquartered in Paris, France. The completion of the transaction follows consultation with the relevant employee representative bodies and approval from the competent regulatory authorities.

The acquisition represents the coming together of two best-in-class organisations to accelerate business solutions that deliver true value for both climate and clients. EcoAct’s portfolio of net zero and nature-based products and services, including consulting, climate data tools, and carbon offset project development, will expand and accelerate Schneider Electric’s global Sustainability Business, a provider of advisory services in the areas of energy management, energy efficiency, renewable energy and environmental commodity procurement, sustainability and net zero consulting, climate risk, sustainability communications, and reporting and disclosure.

The joining of the two organisations expands Schneider's capabilities to provide end-to-end solutions that lead organisations through the net zero transformation and beyond. The company’s advisory services support the development of sustainability strategy and target setting through to decarbonisation across scope one, two and three, enhanced by its AI-led portfolio of digital and data management tools.

“We have long admired the team at EcoAct, and bringing our two organisations together will help us to accelerate the ability to serve our clients all over the world,” says Steve Wilhite, President, Sustainability Business. “Companies understand the urgency to act but continue to face complexities, when it comes to decarbonisation. I’m confident that our combined best-in-class teams will help our clients to accelerate even faster towards their net zero ambitions.”

“Urgent climate action is at the heart of our mission, and I know we’ve found the right partner in Schneider Electric,” says Stuart Lemmon, CEO of EcoAct. “The company’s own demonstrated commitments to net zero – in its own operations and for its clients – speaks loudly in the market, and our EcoActors are excited to join together with another leading advisory team, putting climate and nature centre stage to accelerate sustainable corporate transformation.”

Isha Jain - 2 November 2023

Innovations in Data Center Power and Cooling Solutions

News

The role of generator maintenance in ensuring power resilience

Until now, renewable energy plants in Germany have not been set up for emergency power supply in the event of a power outage. That is about to change, thanks to the award-winning LINDA research project and Crestchic’s load bank technology, which is a critical part of the solution.

What is the LINDA project?

Funded by the Federal Ministry for Economic Affairs and Energy, the project looks at how renewable energy plants could supply power to a local 'island' grid in a decentralised way in the event of a power failure. The project, Local Island Grid Supply and Accelerated Grid Reconstruction, with Decentralised Generation Plants in the Event of Large-scale Power Outages (or the more simple 'LINDA'), seeks to explore, test and implement ways of making power generation systems use renewable energy sources for emergency power supplies.

In 2018, phase one of the project, which involved partners from across academia and industry, including the Augsburg University of Applied Sciences, the Technical University of Munich, LEW Verteilnetz and LEW Wasserkraft, and KIMA automation, won the ISGAN Award (International Smart Grid Action Network) and the Bavarian Energy Prize.

The project included the development of a new emergency generator that successfully integrated renewable decentralised power generation systems, including photovoltaic systems, hydroelectric power plants and a biogas plant, into an independent island grid. In the event of a power failure, the system was designed to supply a local grid with electricity power from existing renewable energy sources.

Emergency power - limitations of the current approach

Historically, emergency power generators have been operated in such a way that power failures can result in a temporary lapse in supply while the generator kicks in. As well as causing momentary outages and fluctuations in supply, these backups are usually supplied by diesel generators. With the new approach, the system is designed to provide a continuous supply in the event of a power failure, using power from multiple decentralised systems, and crucially, favouring renewables as a backup power source.

In pilots of the system, LINDA was able to guarantee the uninterrupted power supply of households in the test communities. This was done without costly retrofitting of the current systems, providing an important building block for the energy transition and improved security of supply.

LINDA 2.0 - automating backup power

In the second phase of the project, LINDA 2.0, the research team is developing a supply concept with battery storage and a diesel generator to provide an additional backup power supply. As well as providing a backup, the system is being designed to automatically balance the fluctuating power generation from decentralised systems and the energy load itself. As well as ensuring a stable and secure power supply without interruptions, the automation will enable the system to shift into emergency mode remotely, without the need for staff to be on site.

Bespoke loadbank solution helps to balance frequency

In order to automate the system, AVS - a German blackout management specialist that provides generators and grid stabilisation systems to a range of industries - worked with the team at Crestchic Loadbanks to create a fully automatic hybrid frequency-controlled power control for generators up to 1300kVA.

Dubbed AVS Greenomic, the solution allows the system to prioritise drawing on renewable energy, for example, CHP, wind power or photovoltaic systems, in order to provide backup power in a blackout scenario, allowing diesel fuel consumption to be reduced by up to 80%. The load bank itself provides a stability of voltage and frequency when switching between different power sources, and maintains a constant 20% load on the generator. Any oversupply of energy is also consumed in a controlled manner, helping to balance the power generation system and smooth out any frequency imbalances.

Mike Derbyshire, European Area Sales Manager at Crestchic, explains, “We’ve worked with AVS for a number of years, so were delighted to collaborate with them on a bespoke solution that would meet the requirements of the LINDA project. Our standard loadbanks and controllers were adapted to allow AVS to add their own control system, and we added additional fuse protection, an interface between the loadbank and the Greenomic assembly and the power connections themselves, all of which enables the system to balance the frequency and ensure and reliable and stable supply. It’s a high-profile project and we’re pleased to have been able to use our technical experience to support and enable the project goals.”

Isha Jain - 30 October 2023

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Vertiv launches UPS for edge and mid-sized applications in EMEA

Vertiv has introduced the Vertiv Liebert APM2, a new energy efficient and scalable power solution to its uninterruptible power supply (UPS) systems portfolio.

The Liebert APM2 is compatible with lithium-ion (Li-ion) and VRLA batteries, and features a compact design that can scale from 30kW to 600kW in a single unit. It offers significant energy savings as compared to less efficient alternatives, and can also parallel with up to four matching units for additional capacity or redundancy. It is a CE certified UPS system available in 400V in Europe, the Middle East, Africa, Latin America, and Asia.

To satisfy the increasing power needs of edge computing applications, as well as the constrained space typical of these sites, it delivers a greater power output in a smaller footprint than similar capacity solutions, with the models requiring up to 45% less space than the predecessor UPS, Vertiv Liebert APM.

The Liebert APM2 operates with high energy efficiency in all modes, up to 97.5% in double-conversion mode; up to 98.8% efficiency when operating in dynamic online mode, which draws power through the bypass line and uses the inverter for balanced output and as an active filter; and up to 99% when operating in ECO mode, which takes advantage of stable grid input conditions to leverage the bypass line. All modes are automated based on user preferences.

The intelligent paralleling feature facilitates load sharing among multiple power modules, even across multiple units. This enables balanced unit runtime and offers automatic failover for enhanced system availability. Intelligent paralleling has also been shown to contribute to energy efficiency.

“Vertiv has introduced, in Liebert APM2 and other UPS systems, enhancements that improve operational efficiency and can contribute to a reduced data centre PUE, while also maintaining system availability,” says Giovanni Zanei, Senior Director, AC Power Global Offering and EMEA Business Leader at Vertiv. “In particular, the dynamic online feature, built on a robust global platform launched in 2018, enhances the already impressive UPS efficiency and has been adopted by energy and availability conscious customers, including many colocators.”

Isha Jain - 3 October 2023

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Sustainable Infrastructure: Building Resilient, Low-Carbon Projects

Centiel supports Sure’s data centres on net zero path

Centiel has completed a project to deploy its award-winning 4th generation, three-phase, modular UPS system CumulusPower in three of Sure’s Tier III data centres on Guernsey.

Sure’s data centres on the Channel Islands keep some of Europe’s largest organisations’ critical data safe and secure in a location outside of mainland UK and Europe.

The upgrade to legacy equipment in data halls four, five and eight this year to CumulusPower has seen the whole facility convert to the latest technology, which offers significantly higher resilience and availability (nine-nines 99.9999999% which equates to milliseconds per year) than previously, in addition to achieving significant energy savings, costs and reducing carbon footprint. Due to the true modular nature of CumulusPower, it is highly efficient, meaning it runs at 97% efficiency compared with <80% for the previous UPS.

Simon Roger, Facilities Manager, Sure, comments, “We chose Centiel’s CumulusPower as the leading power protection technology on the market.

“I am pleased to say that the UPS replacements in data centres four and five are now complete with no more switching events required and the change requests are both closed. We have seen the predicted instant power savings equating to an estimated 20-30% approximately with the current IT load. The UPS are also uber reliable and take up less space and we have saved around seven racks on this installation which can be used for clients.”

Due to the location of the Channel Islands, trained engineers usually need to fly to the islands to complete necessary maintenance work. CumulusPower’s modules can be ‘hot/safe swapped’ in a running load, therefore, Centiel has also trained Sure’s engineers in first level response. Sure’s team can now complete basic monitoring, diagnostics and maintenance of the UPS.

Simon continues, “CumulusPower is unique in the market because it enables UPS modules to be swapped safely by our trained team without switching the UPS off. This safe-hot-swap functionality means even if we need to replace a module and send it for repair, we do not experience any downtime, ensuring maximum availability for our clients.”

Isha Jain - 3 October 2023

Cooling

Innovations in Data Center Power and Cooling Solutions

News

ICS Cool Energy expands with a cold store dedicated team

ICS Cool Energy has announced the expansion of its hire division with a management team dedicated to cold stores. The team of engineering specialists that will manage the UK fleet of low to ultra-low temperature containerised cold store solutions is:

Ralph Howes, Cold Store Major Accounts Manager

Lisa Townsley, Cold Store Business Development Manager, South

Kayla Shaw, Cold Store Business Development Manager, North

Mike Elver, Cold Store Senior Sales Engineer

The company's cold store container units can be used where raw or finished products require temporary or long-term temperature-controlled storage to preserve or increase shelf life.

Cold stores can add storage space and deliver high cooling capacity in combination with precise temperature control from fresh to deep frozen, even in the most severe applications with high ambient temperatures, frequent door openings and long running hours. The units can be also applied in R&D applications, where a temperature-controlled environment is required to enable Accelerated Life Testing (ALT) of critical components.

ICS Cool Energy temperature-controlled containers are available in 10ft, 20ft and 40ft length and feature tried and tested refrigeration technology from Thermo King. The units can be plugged in the 360-500V, 50 or 60Hz power supply to ensure cold or frozen temperatures in the container.

Designed originally for global, seagoing reefer applications, its containers are equipped with features that make them suitable as static cold stores. They are washable with wash down drains, have man trapped person alarms, lighting inside emergency escape release and conform to BRC audit standards. The units can also be adapted to meet customer needs with options including telematics, remote monitoring, and controlled atmosphere. Customers can also benefit from a modular approach, where multiple cold stores, joined together without connecting walls, can be linked with buildings without time consuming engineering, ground works, or long planning permission process.

Isha Jain - 27 September 2023

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Scalable Network Attached Solutions for Modern Infrastructure

Sustainable Infrastructure: Building Resilient, Low-Carbon Projects

Centiel: Protecting power for hypercritical systems

By David Bond, Chairman, Centiel UK

Products are cheap for a reason. If you jumped out of an aircraft, would you want to be wearing a cheap parachute? Probably not!

The same logic applies to an uninterruptible power supply (UPS) protecting hypercritical systems. Selecting the solution which offers the highest level of availability and a low Total Cost of Ownership (TCO) is very important. However, finding the best way to protect critical power is a complex topic and one size doesn’t fit all. For this reason, Centiel’s expert team act as trusted advisors to data centres and facilities across the UK to ensure they always have the optimal UPS solution to reduce their TCO and maximise their uptime, whatever their requirement.

Centiel’s sales team are all engineers and UPS solutions experts and are not required to “sell” UPS. They are required to establish long term relationships with clients and consultants by offering their wealth of experience and expertise. They must take time to understand the challenges faced by the client and always provide the best advice in relation to solutions. If, for example, the best solution is “don’t change the current UPS”, then this is the advice given. Centiel wants its customers to be able to pick up the phone and discuss the best options available for them now and in the future, knowing they will always receive excellent advice and recommendations based on best practice.

It's this long-term vision and close relationships with Centiel’s clients which led to the development of their industry leading UPS solutions. For example, Centiel recently launched StratusPower, which shares all the benefits of the award-winning three phase, true modular UPS CumulusPower - including “9 nines” (99.9999999%) availability to effectively eliminate system downtime; class leading 97.6% on-line efficiency to minimise running costs; true “hot swap” modules to eliminate human error in operation – but now also includes long-life components to improve sustainability.

Centiel’s team have long been at the forefront of solving technology challenges. To develop the innovation that is StratusPower, Centiel listened to customers and understood their concerns about sustainability. For the past four years, its design team has been working to ensure their latest UPS is as sustainable as possible. Uniquely, StratusPower has a 30-year design life and is almost 100% recyclable, providing complete peace of mind in relation to power availability, while helping data centres to achieve net zero targets.

“StratusPower minimises TCO because of its class leading efficiency and low maintenance costs, it is fully scalable, so is unlikely be outgrown and it provides industry leading power availability. This is just one reason Centiel’s experienced team can now advise on the most appropriate options for organisations looking to improve their approach to sustainability and reduce their carbon footprint, as well as maintaining the highest level of availability for critical power protection."

To arrange a discussion about the best UPS to protect your organisation’s critical power or for more information visit Centiel's website.

Click here for more latest news.

Isha Jain - 13 September 2023

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173