Data Centre Infrastructure News & Trends

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

ABB supplies power tech for Applied Digital's AI factory

ABB, a multinational corporation specialising in industrial automation and electrification products, has expanded its collaboration with Applied Digital, an operator of high-performance data centres, to supply power infrastructure for the company’s second AI factory campus in North Dakota, USA.

The latest order, booked in late 2025, covers new medium-voltage electrical architecture designed to support the rising power demands of AI workloads.

Financial terms have not been disclosed.

Powering the AI factory

Applied Digital’s Polaris Forge 2 campus, located near Harwood, North Dakota, is planned to deliver 300 MW of capacity across two buildings due to enter operation in 2026 and 2027. The site is being developed with scope for further expansion.

ABB will provide both low- and medium-voltage electrical systems intended to help the facility achieve high efficiency levels and a low projected PUE.

Todd Gale, Chief Development Officer at Applied Digital, says, “Our partnership with ABB reflects Applied Digital’s commitment to redefining what is possible in data centre scale and performance.

“Polaris Forge 2 represents the next evolution of our AI factory model - beginning with two 150-megawatt buildings with the ability to scale - solidifying our position as a leader in delivering high-performance, energy-efficient AI infrastructure.”

ABB Smart Power President Massimiliano Cifalitti comments, “As AI reshapes data centres, ABB is working with leading digital infrastructure innovators to introduce a new generation of advanced power system solutions.

“The medium voltage architecture developed with Applied Digital is a big step forward for large-scale AI facilities. Working together closely from the start enabled both teams to identify opportunities to drive higher efficiency, performance, and reliability, along with lower costs and faster time to market.”

Applied Digital has reported that the first 200 MW of capacity at Polaris Forge 2 will be leased to a US-based hyperscaler.

The companies’ partnership began in June 2025 with the development of Applied Digital’s first 400 MW AI campus, Polaris Forge 1, in Ellendale, North Dakota.

Both campuses use ABB’s HiPerGuard medium-voltage UPS and medium-voltage switchgear. Moving power distribution to medium voltage using this approach is intended to increase power density, improve efficiency, and support scaling in larger blocks, while also reducing cabling requirements.

For more from ABB, click here.

Joe Peck - 17 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

Products

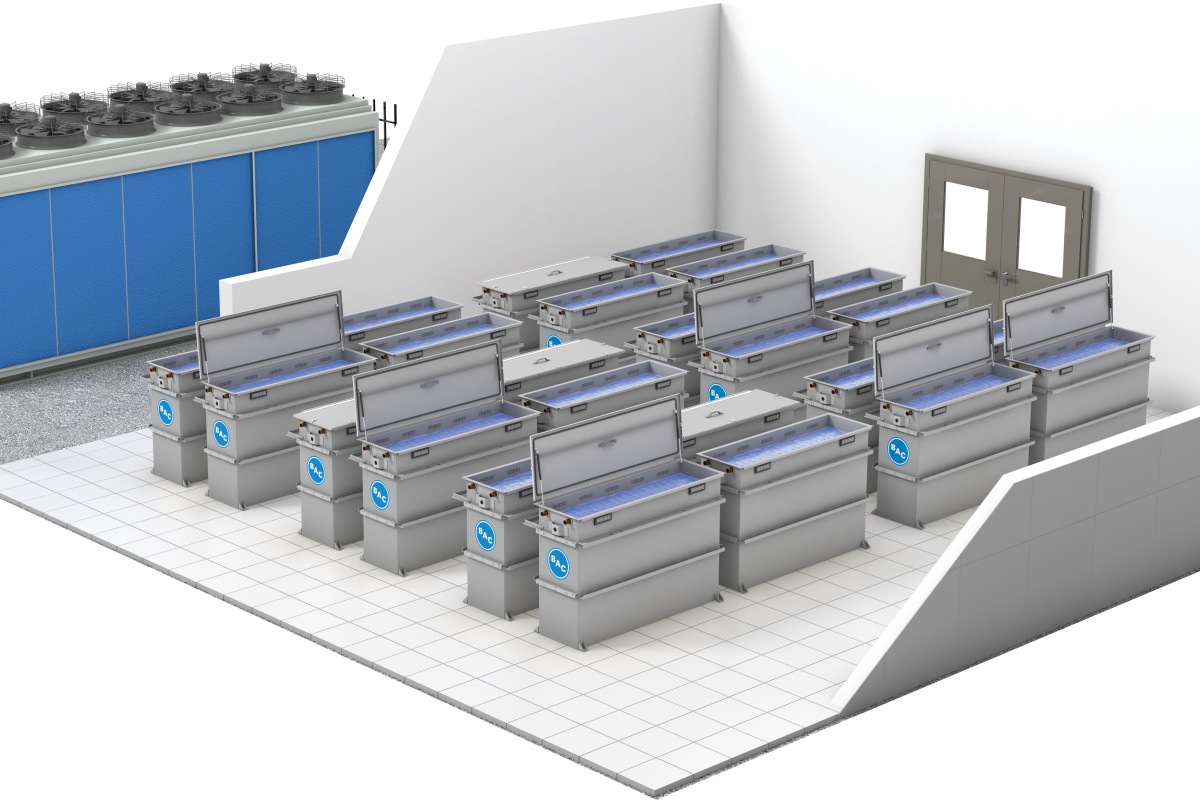

BAC releases upgraded immersion cooling tanks

Baltimore Aircoil Company (BAC), a provider of data centre cooling equipment, has introduced an updated immersion cooling tank for high-performance data centres, incorporating its CorTex technology to improve reliability, efficiency, and support for high-density computing environments.

The company says the latest tank has been engineered to provide consistent performance with minimal maintenance, noting its sealed design has no penetrations below the fluid level, helping maintain fluid integrity and reduce leakage risks.

Dual pumps are included for redundancy and the filter-free configuration removes the need for routine filter replacement.

Design improvements for reliability and ease of operation

The tanks are available in four sizes - 16RU, 32RU, 38RU, and 48RU - allowing operators to accommodate a range of immersion-ready servers. Air-cooled servers can also be adapted for immersion use.

Each unit supports server widths of 19 and 21 inches (~48 cm and ~53 cm) and depths up to 1,200 mm, enabling higher rack densities within a smaller footprint than traditional air-cooled systems.

BAC states that the design can support power usage effectiveness levels of up to 1.05, depending on the wider installation.

The system uses dielectric fluid to transfer heat from servers to the internal heat exchanger, while external circuits can run on water or water-glycol mixtures.

Cable entry points, the lid, and heat-exchanger connections are fluid-tight to help prevent contamination.

The immersion tank forms the indoor component of BAC’s Cobalt system, which combines indoor and outdoor cooling technologies for high-density computing.

The system can be paired with BAC’s evaporative, hybrid, adiabatic, or dry outdoor equipment to create a complete cooling configuration for data centres managing higher-powered servers and AI-driven workloads.

For more from BAC, click here.

Joe Peck - 17 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Liquid Cooling Technologies Driving Data Centre Efficiency

ZutaCore unveils waterless end-of-row CDUs

ZutaCore, a developer of liquid cooling technology, has introduced a new family of waterless end-of-row (EOR) coolant distribution units (CDUs) designed for high-density artificial intelligence (AI) and high-performance computing (HPC) environments.

The units are available in 1.2 MW and 2 MW configurations and form part of the company’s direct-to-chip, two-phase liquid cooling portfolio.

According to ZutaCore, the EOR CDU range is intended to support multiple server racks from a single unit while maintaining rack-level monitoring and control.

The company states that this centralised design reduces duplicated infrastructure and enables waterless operation inside the white space, addressing energy-efficiency and sustainability requirements in modern data centres.

The cooling approach uses ZutaCore’s two-phase, direct-to-chip technology and a low-global warming potential dielectric fluid. Heat is rejected into the facility without water inside the server hall, aiming to reduce condensation and leak risk while improving thermal efficiency.

My Truong, Chief Technology Officer at ZutaCore, says, “AI data centres demand reliable, scalable thermal management that provides rapid insights to operate at full potential. Our new end-of-row CDU family gives operators the control, intelligence, and reliability required to scale sustainably.

"By integrating advanced cooling physics with modern RESTful APIs for remote monitoring and management, we’re enabling data centres to unlock new performance levels without compromising uptime or efficiency.”

Centralised cooling and deployment models

ZutaCore states that the systems are designed to support varying availability requirements, with hot-swappable components for continuous operation.

Deployment options include a single-unit configuration for cost-effective scaling or an active-standby arrangement for enterprise environments that require higher redundancy levels.

The company adds that the units offer encrypted connectivity and real-time monitoring through RESTful APIs, aimed at supporting operational visibility across multiple cooling units.

The EOR CDU platform is set to be used in EGIL Wings’ 15 MW AI Vault facility, as part of a combined approach to sustainable, high-density compute infrastructure.

Leland Sparks, President of EGIL Wings, claims, “ZutaCore’s end-of-row CDUs are exactly the kind of innovation needed to meet the energy and thermal challenges of AI-scale compute.

"By pairing ZutaCore’s waterless cooling with our sustainable power systems, we can deliver data centres that are faster to deploy, more energy-efficient, and ready for the global scale of AI.”

ZutaCore notes that its cooling technology has been deployed across more than forty global sites over the past four years, with users including Equinix, SoftBank, and the University of Münster.

The company says it continues to expand through partnerships with organisations such as Mitsubishi Heavy Industries, Carrier, and ASRock Rack, including work on systems designed for next-generation AI servers.

Joe Peck - 14 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

National Grid upgrading Oxfordshire substation to connect DCs

National Grid, the UK’s largest electricity distribution network, has started work to upgrade its Didcot substation in Oxfordshire, a key infrastructure development that will connect data centres and battery energy storage systems (BESS) to the electricity transmission network.

Situated next to the former Didcot A coal power station and just two miles from the UK’s first AI Growth Zone at Culham, the upgraded substation is aimed at supporting Britain’s digital ambitions while boosting grid capacity for future projects to plug in.

Alongside new data centres, 650MW of battery schemes will connect through the extended facility, completing a transition from ‘coal to clean’ at the site and helping to meet growing demand for flexible, zero carbon power in the region.

Details of the upgrades

The upgrade will see the existing 400kV outdoor air-insulated substation extended with three bays and three supergrid transformers, while a new 132kV indoor gas-insulated switchgear (GIS) facility will be built next door, minimising the footprint of the development and its impact on the environment.

The new GIS facility will feature Hitachi Energy’s EconiQ switchgear technology, a sustainable alternative to sulphur hexafluoride (SF6) - a greenhouse gas commonly used as an electrical insulator - marking another step in National Grid’s commitment to reduce SF6 emissions from its network by 50% by 2030.

Linxon has been appointed as principal contractor to deliver the substation upgrades, building on its collaboration with National Grid on projects such as London Power Tunnels, which will see the UK’s first SF6-free GIS substation at Bengeworth Road.

Work at Didcot comes just months after construction commenced on National Grid’s new Uxbridge Moor substation in neighbouring Buckinghamshire, which is due to connect over a dozen new data centres and which will also use SF6-free switchgear.

Peter Hancock, Project Director at National Grid Electricity Transmission, says, “Our Didcot substation extension marks another step forward in powering the UK’s digital future.

"By enabling new data centres and battery storage systems to connect to the grid, we’re supporting both the energy transition and the growth of the digital economy regionally and nationally.

“With SF6-free technology at its heart, this project reflects our commitment to building a cleaner, greener electricity network for generations to come.”

Angel Guijarro, Managing Director of Linxon Europe, adds, “Linxon’s appointment to this project is a testament to our strong partnership with National Grid and our shared vision for a sustainable energy future.

"We are committed to delivering a turnkey solution that will enhance the reliability and efficiency of Didcot substation, benefitting both local and national communities.”

Electricity demand in Britain is expected to double by 2050, with demand from data centres alone set to triple from 3% of the country’s total in 2025 to 9% by 2035.

For more from National Grid, click here.

Joe Peck - 14 November 2025

Data Centre Infrastructure News & Trends

Enterprise Network Infrastructure: Design, Performance & Security

Events

News

Capacity Europe 2025 notes record attendance

The 24th edition of Capacity Europe, an event for global digital infrastructure and connectivity, wrapped up last week after three packed days and record-breaking attendance, cementing its status as a major event for the global connectivity ecosystem.

Hosted by provider of digital infrastructure events techoraco at the InterContinental London – The O2, the event brought together over 3,600 senior leaders from more than 100 countries, marking the largest turnout in its history.

Discussions around a changing landscape

This year’s event showcased the industry’s rapid transformation, fuelled by advances in AI and the expansion of data infrastructure, reshaping the telecommunications and digital infrastructure landscape.

With a focus on innovation, investment, and next-generation network strategy, Capacity Europe 2025 placed a spotlight firmly on the evolving digital ecosystem.

Opening the show was the keynote panel 'Disrupt to Lead: The New Telco Mindset'. The session explored how next-generation infrastructure is reshaping the telecom industry and driving operators toward new business models.

Panellists examined the evolution from traditional carriers to "techcos", blending infrastructure with value-added services and platform-based offerings that deliver on-demand, flexible experiences for enterprise customers.

Moderated by Silvia Peneva, Managing Director of GLF & ITW at techoraco, the panel featured industry figures including Annette Murphy (CCO, Colt Technology Services), Enrico Bagnasco (CEO, Sparkle), Dimitrios Rizoulis (SVP Global Connectivity, T Wholesale), Fánan Henriques (Director of Product & International Business, Vodafone Business), Valerie Cussac (CEO, Orange Wholesale International), and Mohammed Al-Abbadi (Group Chief Carrier & Wholesale Officer, STC).

“Capacity Europe 2025 has been our most impactful year yet,” notes Liss Boot-Handford, Product Director at Capacity Media, techoraco. “The energy, collaboration, and level of deal-making we’ve seen this year demonstrates how vital this event is to the industry’s future.”

Key milestones

• More than 3,600 senior leaders from over 100 countries• Upwards of 80 keynote sessions and panels• Over 250 exhibitors and sponsors• Record number of partnership deals signed on site

Across its keynote sessions and panel discussions, the event delivered insights from leaders across telecoms, cloud, edge, investment, and AI infrastructure.

Highlights included explorations of the global dynamics redefining connectivity and the race to expand digital capacity to meet AI-driven demand.

As Capacity Europe looks ahead to its milestone 25th anniversary in 2026, this year’s success sets the stage for another chapter in the evolution of global digital connectivity.

The 2026 edition will return to the InterContinental London – The O2, from 13-16 October 2026.

For more on Capacity Europe, click here.

Joe Peck - 12 November 2025

Data Centre Build News & Insights

Data Centre Infrastructure News & Trends

Data Centre Projects: Infrastructure Builds, Innovations & Updates

Innovations in Data Center Power and Cooling Solutions

Vertiv to supply Digital Realty's new Italy campus

Vertiv, a global provider of critical digital infrastructure, today announced it will supply infrastructure for ROM1, Digital Realty's first data centre in Italy and which has a planned capacity exceeding 3 MW.

The agreement extends the suite of Vertiv systems and existing technology implementations with Digital Realty across European locations, including Paris, Madrid, and Amsterdam.

The ROM1 facility will feature advanced cooling and power infrastructure designed specifically for high-performance computing (HPC) environments.

The technology implementation includes free-cooling systems that leverage Rome's climate conditions and energy-efficient power management systems designed to support high-density workloads.

The ROM1 project

The project will be implemented in phases, with the facility planned to begin operations in 2027.

ROM1 will serve as a carrier-neutral facility optimised for AI and machine learning workloads. Its strategic location aims to establish Rome as a key digital hub, connecting to major Mediterranean cities through fibre networks and submarine cables.

Expansion plans also include connectivity in Barcelona, launching in early 2026.

The new facility will support the company’s growth in the Mediterranean, complementing its existing data centres in Marseille, Athens, and Crete.

Alessandro Talotta, Managing Director, Italy at Digital Realty, says, "Rome is emerging as a crucial gateway for digital infrastructure between Europe and the Mediterranean.

"The cutting-edge technologies selected for ROM1 will help establish it as a strategic AI hub, setting new benchmarks for energy efficiency and performance in high-performance computing."

Karsten Winther, President for EMEA at Vertiv, adds, "The growing adoption of AI applications is driving the need for more sophisticated data centre infrastructure.

"Our cooling and power solutions are built on decades of experience in supporting the most demanding applications and are designed for projected scalability while helping customers meet their efficiency objectives."

Technical details of ROM1 include AI-ready cooling systems that, Vertiv says, adapt to varying workload demands, as well as high-efficiency power distribution designed for intensive computing.

The facility incorporates smart environmental controls that respond to real-time conditions and are integrated with alternative energy sources.

The two companies say these technological choices reflect their joint focus on supporting advanced computing needs while minimising energy consumption and environmental impact.

For more from Vertiv, click here.

Joe Peck - 11 November 2025

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

News

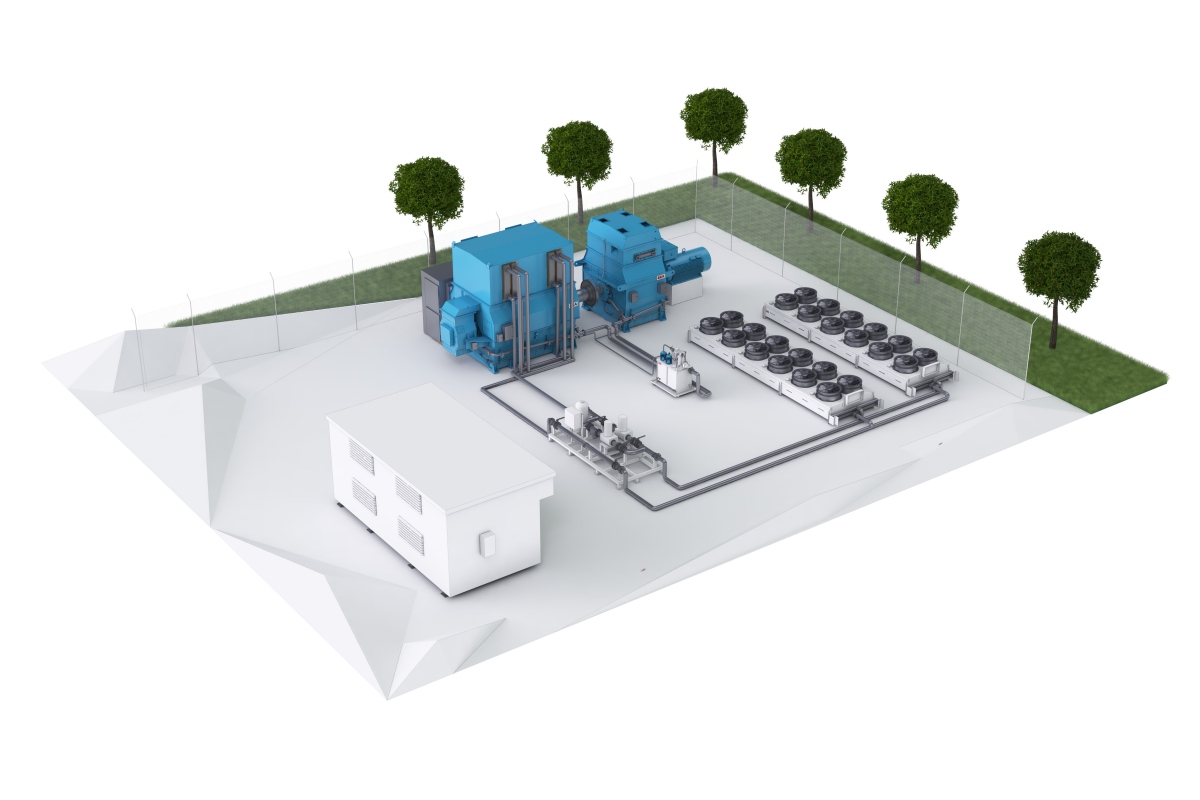

ABB, VoltaGrid to strengthen power stability for AI expansion

ABB, a multinational corporation specialising in industrial automation and electrification products, has secured three new orders from VoltaGrid, a Texas-based microgrid power generation company, to provide grid stabilisation technology supporting data centres across the United States.

The projects will supply stable and reliable electricity to facilities currently under construction for AI infrastructure. The contracts were booked during the first three quarters of 2025; financial details were not disclosed.

Strengthening grid resilience for AI-driven demand

To meet the growing power needs of data centres, ABB will deliver a package of 27 synchronous condensers with flywheels and prefabricated eHouse units. These include power control, automation, and excitation systems integrated into the synchronous condenser panels.

The units deliver instantaneous inertia, support short-circuit faults, and regulate network voltage by supplying or absorbing reactive power, helping maintain grid stability as electricity demand increases.

VoltaGrid will provide its natural-gas-fuelled power systems, designed for rapid deployment and to meet the specific power requirements of hyperscale data centres.

Project delivery will begin in December 2025, with the first systems expected to be operational by April 2026.

Nathan Ough, CEO of VoltaGrid, claims, “ABB’s synchronous condensers are vital for meeting the energy demands of next-generation technologies like AI data centres, thanks to their proven ability to ensure grid stability and enhance overall power system resilience.

"Partnering with ABB allows us to accelerate project execution and meet the growing performance demands of AI operations.”

Supporting the evolving data centre power ecosystem

According to recent estimates, data centres accounted for around 1.5% of global electricity consumption in 2024, with the United States responsible for 45% of that total.

By 2030, US data centre power use is projected to represent almost half of the country’s total growth in electricity demand. Analysts predict that, by the same year, the US will consume more electricity for data processing than for manufacturing energy-intensive materials such as aluminium, steel, cement, and chemicals.

As global demand for AI and cloud computing accelerates, ABB says it continues to provide electrification, automation, and digital technologies to "ensure secure and efficient energy systems for data centre operators."

Per Erik Holsten, President of ABB’s Energy Industries division, says, “ABB is proud to partner with VoltaGrid and support the evolving energy ecosystem in the US.

"Data centres have become critical national infrastructure and maintaining grid stability has moved from being optional to essential. Reliable, efficient power generation is key to enabling their continued growth.”

Kristina Carlquist, Head of the Synchronous Condenser Product Line at ABB’s Motion High Power division, adds, “Although synchronous condensers resemble large motors or generators, their real strength lies in grid support.

"As data centres expand, these machines are becoming increasingly important for providing inertia and short-circuit strength. For VoltaGrid, they will help ensure stable and resilient microgrid operation.”

For more from ABB, click here.

Joe Peck - 10 November 2025

Data Centre Business News and Industry Trends

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Insights into Data Centre Investment & Market Growth

CEL Critical Power opens $40m US manufacturing facility

CEL Critical Power, an Ireland-based manufacturer of switchgear and power equipment for the global data centre industry, has opened its first large-scale manufacturing facility in Williamsburg, Virginia, USA.

The new 400,000-square-foot (37,161-square-metre) plant, operational since June, represents a $40 million (£30.3 million) investment and a major step in CEL Critical Power’s international expansion.

The facility increases the company’s manufacturing footprint in the United States - the world’s largest and fastest-growing market for AI and cloud infrastructure - while strengthening its ability to serve key data centre clients.

Strengthening US presence and creating skilled jobs

The Virginia expansion is intended to generate more than 250 skilled roles within the next year, rising to 500 by 2030 across engineering, manufacturing, quality assurance, logistics, and site services.

The facility forms part of CEL Critical Power’s strategy to reach $500 million (£379.5 million) in annual revenue by 2030, supported by its existing operations in Ireland. Together, its global production capacity now exceeds 500,000 square feet (46,451 square metres).

A key component of the project is CEL Critical Power’s collaboration with the Virginia Economic Development Partnership (VEDP) and its registration with the US Department of Defense 'SkillBridge' programme.

Through partnerships with Naval Station Norfolk and regional alliances, the initiative offers active-duty service members and military veterans opportunities to transition into civilian technical careers.

Manufacturing data centre power

CEL Critical Power designs and manufactures power distribution units (PDUs), remote power panels (RPPs), and switchgear systems for data centre environments.

The company says its engineering approach emphasises reliability, efficiency, and short production cycles, developed through close collaboration with customers from concept through to deployment.

Niall McFadden, Group CEO of CEL Critical Power, comments, “The opening of our first US manufacturing facility marks an important step in CEL Critical Power’s growth strategy.

"We have listened closely to our customers and recognise their need for trusted partners who can scale alongside them in the United States. This $40 million investment reflects our long-term commitment to supporting those customers in a rapidly expanding market.

“Thanks to the support of the Virginia Economic Development Partnership, and our collaboration with the Department of Defense SkillBridge programme and Naval Station Norfolk, we plan to create up to 500 skilled jobs in Virginia by 2030."

Alan McCartney, Chief Sales Officer at CEL Critical Power, adds, “As a manufacturer of custom power systems for the global data centre industry, we are expanding our capacity to meet growing demand from customers investing in AI and cloud infrastructure.

“Our design-for-manufacture approach allows us to address specific technical and scheduling requirements and to deliver custom-built systems at scale. Our products are designed to support the next generation of AI workloads and the emerging Neo-Cloud sector.”

Graham Carr, Vice President of Sales, North America, CEL Critical Power, says, “CEL Critical Power is proud to invest in Virginia, working with VEDP, the DoD SkillBridge programme, and Naval Station Norfolk to create meaningful career pathways for veterans while supporting the state’s growing technology sector.

"Virginia offers a strong supply chain, excellent infrastructure, and a deep pool of technical talent.”

Joe Peck - 10 November 2025

Data Centre Build News & Insights

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Quantum Computing: Infrastructure Builds, Deployment & Innovation

Oxford technology supplied to quantum-AI data centre

Oxford Instruments NanoScience, a UK provider of cryogenic systems for quantum computing and materials research, has supplied one of its advanced Cryofree dilution refrigerators, the ProteoxLX, to Oxford Quantum Circuits’ (OQC) newly launched Quantum-AI data centre in New York.

As the first facility designed to co-locate quantum computing and classical AI infrastructure at scale, the centre will use the ProteoxLX’s cryogenic capabilities to support OQC’s next-generation quantum processors, helping to advance the development of quantum-enabled AI applications.

Supporting quantum and AI integration

The announcement follows the opening of OQC’s New York-based Quantum-AI data centre, powered by NVIDIA CPU and GPU Superchips. The facility represents a major step towards practical, scalable quantum computing.

Within OQC’s logical-era quantum computer, OQC GENESIS, the ProteoxLX provides the ultra-low temperature environment needed to operate its 16 logical qubits, enabling over 1,000 quantum operations.

This capability aims to drive innovation across finance, security, and data-intensive sectors ranging from faster financial modelling and optimisation to quantum-assisted machine learning.

Oxford Instruments NanoScience says the collaboration highlights its expanding role in the global quantum computing landscape.

OQC’s data centre installations across Europe, North America, and Asia contribute to a distributed quantum infrastructure, accelerating the application of superconducting qubit technologies for industries such as pharmaceuticals.

Matthew Martin, Managing Director at Oxford Instruments NanoScience, comments, “We’re proud to support OQC in building the infrastructure that will define the next generation of computing, and it is a privilege to collaborate with our longstanding partner on this project.

“Our ProteoxLX is designed to allow users to scale, enabling them to maximise qubit counts with a large sample space and capacity for coaxial lines, so we’re excited to see how OQC will harness this platform to accelerate breakthroughs in real-world application performance.”

Simon Phillips, CTO at OQC, adds, “Oxford Instruments NanoScience’s contribution supports the centre’s goal of creating a hybrid quantum-classical computing capability, without modifying the data centre environment or generating the need for additional cooling.”

About ProteoxLX

Designed for quantum computing applications, the ProteoxLX forms part of Oxford Instruments NanoScience’s latest dilution refrigerator range, all built on a modular framework for cross-compatibility and adaptable cryogenic setups.

It offers a large sample space, extensive coaxial wiring capacity, low-vibration operation, and integrated signal conditioning for longer qubit coherence times.

The system delivers over 25 µW of cooling power at 20 mK, a base temperature below 7 mK, and several watts of cooling capacity at 4 K via twin pulse tubes.

Two fully customisable secondary inserts enable optimised cold-electronics layouts and high-capacity I/O lines, interchangeable across the Proteox family.

Joe Peck - 7 November 2025

Data Centre Business News and Industry Trends

Data Centre Infrastructure News & Trends

Innovations in Data Center Power and Cooling Solutions

Insights into Data Centre Investment & Market Growth

Mission Critical Group acquires Leman Engineering

Mission Critical Group (MCG), a critical power infrastructure company, has announced the acquisition of Leman Engineering and Consulting (LEC), a US manufacturer of switchgear, control systems, and power distribution equipment.

The acquisition aims to strengthen MCG’s US Midwest manufacturing presence, expand its engineering capabilities, and establish LEC as MCG’s R&D hub for power generation engineering.

The company says this hub focuses on switchgear innovation for onsite generation, prime power, generator paralleling, behind-the-meter systems, and microgrids.

An electric collaboration

With experience in prime power distribution design, precision manufacturing, and engineering, MCG hopes LEC will strengthen its unified power and energy infrastructure platform, delivering high-performance electrical systems across data centre, healthcare, industrial, oil and gas, and other critical markets.

Its capabilities in UL 891 switchboards, UL 1558 switchgear, and medium-voltage equipment should expand MCG’s technical depth and manufacturing reach.

The establishment of MCG’s R&D hub is also intended to align with strategic university partnerships specialising in power engineering and advance innovation and workforce development across the electrical manufacturing sector.

“We’re proud to join MCG and contribute to its continued growth and innovation,” comments Randy Leman, President of Leman Engineering and Consulting.

Randy will now serve as Vice President of Engineering and Product Management for Electrical Equipment at MCG. The Indiana team will continue operating under existing leadership, maintaining its local presence and customer focus.

The addition of LEC marks MCG’s second acquisition in 2025 and sixth in the past 24 months.

With more than one million square feet (93,000 square metres) of US manufacturing space, MCG says it continues to expand its capacity to design, build, deliver, and service resilient power infrastructure US-wide.

For more from Mission Critical Group, click here.

Joe Peck - 7 November 2025

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173