The liquid future of data centre cooling

Author: Beatrice

By Markus Gerber, Senior Business Development Manager, nVent Schroff

Demand for data services is growing and yet, there has never been greater pressure to deliver those services as efficiently and cleanly as possible.

As every area of operation comes under greater scrutiny to meet these demands, one area in particular – cooling – has come into sharp focus. It is an area not only ripe for innovation, but where progress has been made that shows a way forward for a greener future.

The number of internet users worldwide has more than doubled since 2010. Furthermore, as technologies emerge that are predicted to be the foundation of future digital economies, demand for digital services will rise not only in volume, but also sophistication and distribution.

This level of development brings challenges for energy consumption, efficiency, and architecture. The IEA estimates that data centres are responsible for nearly 1% of energy-related greenhouse gas (GHG) emissions. While it acknowledges that since 2010, emissions have grown modestly despite rapidly growing demand, through energy efficiency improvements, renewable energy purchases by ICT companies and broader decarbonisation of electricity grids, it also warns that to align with the net zero by 2050 scenario, emissions must halve by 2030.

This is a significant technical challenge. Firstly, in the last several decades of ICT advancement, Moore’s Law has been an ever-present effect. It states that compute power would more or less double, with costs halving, every two years or so. As transistor densities become more difficult to increase as they get into the single nanometre scale, the CEO of NVidia has asserted that Moore’s Law is effectively dead. This means that in the short term, to meet demand, more equipment and infrastructure will have to be deployed, in greater density.

All changes will impact upon cooling infrastructure and cost

In this scenario of increasing demand, higher densities, larger deployments, and greater individual energy demand, cooling capacity must be ramped up too.

Air as a cooling medium was already reaching its limits, being as it is, difficult to manage, imprecise, and somewhat chaotic. As rack systems become more demanding, often mixing both CPU and GPU-based equipment, individual rack demands are approaching or exceeding 30W each. Air-based systems also tend to demand a high level of water consumption, for which the industry has also received criticism in the current environment.

Liquid cooling technologies have developed as a means to meet the demands of both volume and density needed for tomorrow’s data services. Liquid cooling takes many forms, but the three primary techniques currently are direct-to-chip, rear door heat exchangers, and immersion cooling.

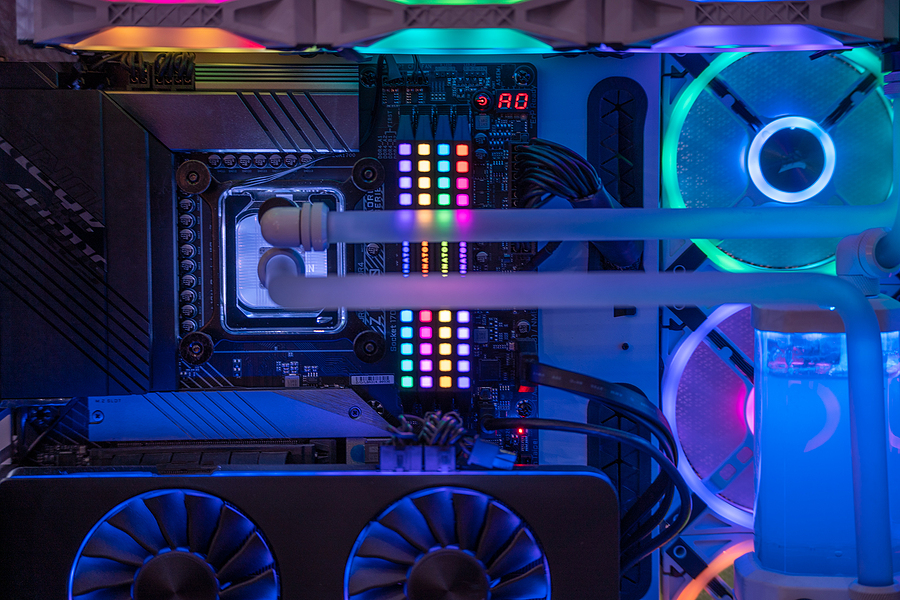

Direct to chip (DtC) cooling is where a metal plate sits on the chip or component, and allows liquid to circulate within enclosed chambers carrying heat away. It is often used with specialist applications, such as high performance compute (HPC) environments.

Rear door heat exchangers are close-coupled indirect systems that circulate liquid through embedded coils to remove server heat before exhausting into the room. They have the advantage of keeping the entire room at the inlet air temperature, making hot and cold aisle cabinet configurations and air containment designs redundant, as the exhaust air cools to inlet temperature and can recirculate back to the servers.

Immersion technology employs a dielectric fluid that submerges equipment and carries away heat from direct contact. This enables operators to immerse standard servers with certain minor modifications such as fan removal, as well as sealed spinning disk drives. Solid-state equipment generally does not require modification.

An advantage of the precision liquid cooling approach is that full immersion provides liquid thermal density, absorbing heat for several minutes after a power failure without the need for back-up pumps.

Cundall’s liquid cooling findings

According to a study by engineering consultant, Cundall, liquid cooling technology outperforms conventional air cooling.

This is principally due to the higher operating temperature of the FWS, compared to the cooling mediums used for air cooled solutions. In all air cooled cases, considerable energy and water is consumed to arrive at a supply air condition that falls within the required thermal envelope. The need for this is avoided with liquid cooling.

There were consistent benefits found, in terms of energy efficiency and consumption, water usage and space reduction, in multiple liquid cooling scenarios, from hybrid to full immersion, as well as OpEx and CapEx benefits.

In hyperscale, colocation and edge computing scenarios, Cundall found the total cost of cooling ITE per kW consumed in liquid versus the base case of current air cooling technology, varied from 13-21% less.

In terms of emissions, Cundall states that PUE and TUE are lower for the liquid cooling options in all tested scenarios. Expressing the reduction in terms of kg CO2 per kW of ITE power per year, results saw more than 6% for colocation, rising to almost 40% for edge computing scenarios.

What does the future hold in terms of liquid cooling?

Combinations of liquid and air cooling techniques will be vital in providing a transition, especially for legacy instances, to the kind of efficiency and emission-conscious cooling needs of current and future facilities. Though immersion techniques offer the greatest effect, hybrid cooling offers an improvement over air alone, with OpEx, performance and management advantages.

Even as the data infrastructure industry institutes initiatives to better understand, manage and report sustainability efforts, more can be done to make every aspect of implementation and operation sustainable.

Developments in liquid cooling technologies are a step forward that will enable operators and service providers to meet demand, while ensuring that sustainability obligations can be met. Initially, hybrid solutions will facilitate legacy operators to make the transition to more efficient and effective systems, while more advanced technologies will ensure new facilities more efficient, even as capacity is built out to meet rising demand.

By working collaboratively with the broad spectrum of vendors and service providers, cooling technology providers can ensure that requirements are met, enabling the digital economy to develop to the benefit of all, while contributing towards a liveable future.