Innovations in Data Center Power and Cooling Solutions

Data Centres

Innovations in Data Center Power and Cooling Solutions

Eaton delivers energy savings in its new UPS

Eaton, an intelligent power management company, has announced the launch of its 9PX Gen2 5-11kW UPS, a new product that adds benefits to its 9PX solution through advanced technology upgrades and customer-centric enhancements. It seeks to deliver best-in-class power management and battery backup for critical equipment in data centres, distributed IT, edge networks, network closets, and server rooms. Eaton DPQ Product Line Manager Christophe Jammes comments, “Our latest UPS delivers market-leading efficiency of up to 97.2% in the 11kW unit thanks to innovative silicon carbide (SiC) components that not only use less power, and therefore cut energy bills, but also put operators one step ahead in emissions reduction. “When it comes to physical footprint,” he adds, “9PX Gen2 is the compact UPS that leads the way, delivering 11kW in just 4U. It offers an unmatched and Energy Star-qualified 11% more power in a space 33% smaller than its predecessor.” Every 9PX Gen2 UPS comes with a cybersecure Gigabit Network Card – enabling remote configuration, management, and upgrade of the entire UPS fleet, including full integration with Eaton’s Brightlayer Data Centers suite. Speaking of the product’s features, Christophe says, “In what we believe to be a UPS ’world first’, flexible ‘combo’ C39 outlets securely connect both C14 and C20 power cords – ending the guessing game of attempting to specify the required number of C13 (10A) and C19 (16A) outlets.” Predictive machine learning pinpoints timing for battery replacement by fast, convenient ‘hot swap’ – preventing unexpected downtime and the unnecessary expense of replacing batteries too soon. Optimised ABM+ charging also increases battery lifespan by up to 50%. 9PX Gen2 comes with a three-year warranty on electronic components and a two-year warranty on batteries (full three-year upon registration). There is also the option to extend coverage for the longer term to up to seven years of protection and support.

For more from Eaton, click here.

Joe Peck - 23 May 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Vertiv accelerates AI infrastructure evolution

Vertiv, a global provider of critical digital infrastructure, today confirmed its strategic alignment with NVIDIA’s announcement of an AI roadmap to deploy 800 VDC power architectures for the next generation of AI-centric data centres. Paving the way for future-ready designs, Vertiv’s 800 VDC power portfolio is scheduled for release in the second half of 2026 - ahead of NVIDIA Kyber and NVIDIA Rubin Ultra platform rollouts.

Vertiv aligns with the NVIDIA AI roadmap to stay one GPU generation ahead, enabling customers to deploy their power and cooling infrastructure in sync with NVIDIA’s next-generation compute platforms. Vertiv provides end-to-end power, cooling, integrated infrastructure and services to support AI factories and other data centre deployments.

As rack power requirements in AI environments scale beyond 300 kilowatts, 800 VDC enables more efficient, centralised power delivery by reducing copper usage, current, and thermal losses. Vertiv’s upcoming portfolio will feature centralised rectifiers, high-efficiency DC busways, rack-level DC-DC converters, and DC-compatible backup systems, expanding its broad, end-to-end power management portfolio that already includes a robust AC power train.

“As GPUs evolve to support increasingly complex AI applications at giga-watt scale, power and cooling providers need to be equally innovative to provide energy-efficient and high-density solutions for the AI factories. While the 800 VDC portfolio is new, DC power isn’t a new direction for us, it’s a continuation of what we’ve already done at scale,” says Scott Armul, Executive Vice President of Global Portfolio and Business Units at Vertiv.

“We’ve spent decades deploying higher-voltage DC architectures across global telecom, industrial, and data centre applications. We’re entering this transition from a position of strength and bringing real-world experience to meet the demands of the AI factory.”

Vertiv’s experience in DC power spans more than two decades of ±400 VDC deployments, broadened by strategic acquisitions during the early 2000s. These solutions support critical loads in global telecom networks, integrated microgrids, and mission-critical facilities. Vertiv says that this foundation establishes the company as a trusted leader in the safe design, deployment, and operation of higher-voltage DC architectures, with proven scale, portfolio, and long-term serviceability.

Designed for homogeneous AI zones in hyperscale environments, Vertiv’s 800 VDC portfolio is a key pillar of its 'unit of compute' strategy - a systems-level design engineered to enable all infrastructure components - to interoperate as one modular and scalable system, matching infrastructure demands of next-generation GPUs. Vertiv’s support for both AC and DC architectures is a strategic differentiator in the evolving AI data centre landscape.

For more from Vertiv, click here.

Simon Rowley - 19 May 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

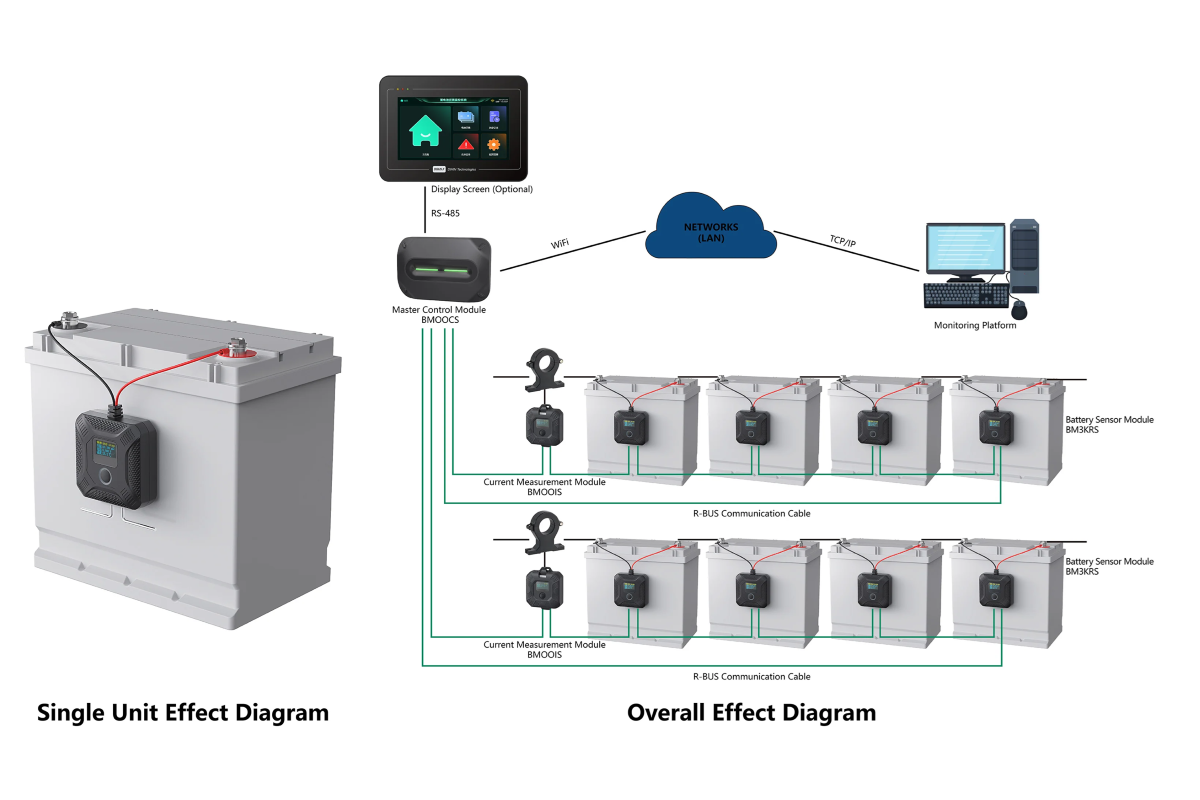

leagend UPS solution safeguards backup power supply

According to leagend Solutions, the backup power supply is the second heart of a data centre - and any issue that happens to it will cause huge economic losses or even disasters.

As a result, leagend's UPS battery management solution is a professional innovation exclusively developed for backup power applications such as data centres, telecom bases, and other applications seeking energy saving and renewable energy solutions. It guarantees the UPS batteries operate normally by monitoring and managing the key parameters of the batteries in real-time to ensure they supply stable power continuously under the accidence of a power outage.

Furthermore, it integrates with advanced technologies like data collection, data transfer and data processing to offer comprehensive monitoring, cloud storage, visualised data analyses and tailored services for customers.

Its capacity can be up to over 200 batteries with two different voltages simultaneously. In addition, leagend has integrated 5G and AI chips to the next-generation BMS.

– leagend Solutions has been specialising in researching and developing batteries technologies, battery testing technologies, battery monitoring and managing systems and solutions ever since the company’s establishment in 2014. Intelligence, precision, safety and low energy consumption are always the foundation and ideology of its technology research and development.

Until now, leagend Solutions has offered the following innovations: smart lead-acid battery testers, UPS battery monitoring solutions, lead-acid battery charger ODM solutions, Coulomb counter solutions, and more. The company’s battery products have been widely applied to multiple professional fields such as lead-acid battery manufacturing, data centre power supply chains, energy-saving, renewable energy, telecoms, and emergency backup power applications.

For more from leagend Solutions, click here.

Simon Rowley - 9 May 2025

Data Centre Infrastructure News & Trends

Data Centres

Hyperscale Data Centres: Scale, Speed & Strategy

Innovations in Data Center Power and Cooling Solutions

News

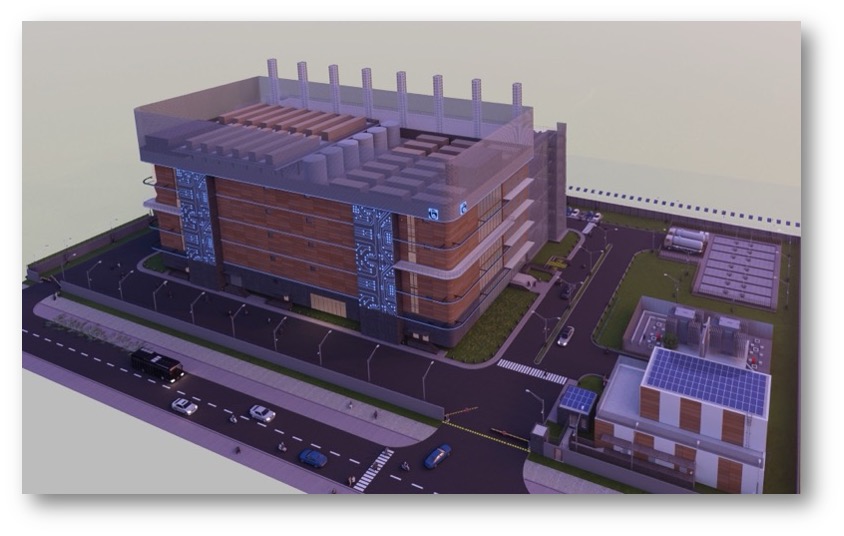

Techno Digital to power India’s digital infrastructure

Techno Electric & Engineering Company Ltd. (TEECL), one of India’s most trusted names in power infrastructure for over four decades, has officially launched Techno Digital Infra Pvt, its wholly-owned digital infrastructure arm.

Backed by an ambitious investment plan of $1 billion, Techno Digital plans an integrated network of hyperscale and edge data centres targeting a cumulative capacity of 250 MW spread across the country. This strategic move marks a transformative leap to revolutionise India’s digital economy, aligned with the Government of India’s flagship programme, Digital India.

Rooted in strong credentials of engineering, procurement and construction excellence, TEECL is leveraging its deep domain expertise in power infrastructure and sustainability to build an efficient, reliable, and eco-conscious network of data centres. The launch of Techno Digital underscores the Group’s vision to become a cornerstone in India’s data revolution - bringing scalable, secure, and low-latency digital infrastructure to metro and non-metro regions alike.

“The decision to enter the digital infrastructure space is both timely and visionary,” says Padam Prakash Gupta, Managing Director, Techno Electric & Engineering. “India’s data economy is poised for exponential growth, and with our legacy in power infrastructure and EPC, we see ourselves as natural enablers of this transformation. Techno Digital is not just a business venture - it’s a national mission to bridge the digital divide and power a truly connected India.”

The journey begins at Chennai, where Techno is building a 36 MW hyperscale data centre within SIPCOT IT Park, Siruseri. This Rated-3 facility spans approximately two Lakh square foot, houses up to 2,400 racks, and integrates renewable energy with Battery Energy Storage Systems (BESS) for continuous sustainability, adiabatic cooling for water efficiency (WUE), 25% green cover and a facility design PUE of 1.35. Future locations for hyperscale facilities include Kolkata and Noida, positioning Techno Digital as a key player in supporting India’s digital growth.

“We are not just building data centres, we are powering India’s digital revolution,” adds Amit Agrawal, President, Techno Digital. “Our hybrid strategy integrating hyperscale and edge will redefine how data is hosted, processed, and delivered. Whether it’s AI, OTT, fintech, or governance, our infrastructure is designed for the next decade of digital growth. We are empowering our ecosystem partners to offer unique solutions around cloud, security and managed services, thereby ensuring cutting edge technology’s ubiquitous availability and affordability.

As part of its nation-building vision, Techno has partnered with RailTel Corporation of India, a Government of India enterprise under the Ministry of Railways, to develop edge data centres in 102 cities across 23 Indian states. This landmark project will be the largest deployments of its kind, bringing low-latency computing closer to users in Tier 2 and Tier 3 cities, empowering sectors such as AI, BFSI, telecom, OTT, e-sports, healthcare, e-governance, and manufacturing.

“This partnership with RailTel embodies our core belief that digital infrastructure should be democratised to transform India into a digitally empowered society and knowledge-based economy,” says Ankit Saraiya, Director & CEO, Techno Electric & Engineering. “From AI workloads and 5G to cloud-native applications, we’re enabling India to process data where it’s consumed, reducing latency, energy use, and cost. Our edge deployment model is not just technically superior, it’s a complete ecosystem that encompasses all aspects of a digital infrastructure. We are honoured to be RailTel’s trusted partner in this national mission.”

Simon Rowley - 7 May 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Mission Critical Group acquires DVM Power + Control

Mission Critical Group (MCG), a provider of innovative products specialising in design, manufacturing, delivery and service of electrical system solutions, has announced that it has acquired DVM Manufacturing (DVM Power + Control), a manufacturer of low- and medium-voltage electrical distribution equipment.

The acquisition significantly expands MCG’s manufacturing footprint and service capabilities in electrical systems for data centres, industrial facilities and other mission critical applications.

With 350,000 square feet of production space in Pennsylvania, Georgia, and Connecticut, DVM expands MCG’s footprint to over one million square feet of manufacturing capacity. The acquisition also strengthens MCG’s field services, drives innovation, and enhances technical expertise by adding DVM’s skilled workforce, providing customers with more solutions and stronger support.

DVM designs and produces low- and medium-voltage electrical distribution equipment, including switchboards, switchgear, relay panels, power distribution units (PDUs), bypasses, power/cooling module 'skid' manufacturing and control systems. Its Naugatuck, Connecticut facility specialises in retrofits, breaker rebuilds and switchgear modernisation, further bolstering MCG’s services and power offerings.

“DVM’s expertise advances MCG’s manufacturing and aftermarket services, driving growth and customer satisfaction for our innovative, high-quality solutions,” says Jeff Drees, CEO of Mission Critical Group. “With DVM’s added capacity and technical strengths, we are also expanding our geographic reach, boosting product development and optimising power service offerings to better support data centres and other mission critical environments.”

Robert Ricci, CEO of DVM Power + Control, adds, “This partnership is a natural fit, built on a shared commitment to innovation, excellence and customer value. Having worked with MCG’s leadership for 30 years, I can attest to their deep industry knowledge and strategic expertise. This collaboration expands our resources, enhances engineering capabilities and improves career growth, ensuring a stronger future for our team.”

DVM will operate as a Mission Critical Group Company alongside JTS and Point Eight Power, continuing to elevate MCG’s leadership in electrical system solutions. As part of the transition, Ricci will continue to lead DVM as its President and oversee MCG’s low- and medium-voltage electrical equipment manufacturing.

With five acquisitions in two years, MCG says that this latest addition marks another milestone in its rapid growth, while reinforcing its commitment to innovation and excellence in mission critical solutions.

For more from Mission Critical Group, click here.

Simon Rowley - 25 April 2025

Data Centre Build News & Insights

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Renewables and Energy: Infrastructure Builds Driving Sustainable Power

2025 ESG Report: Data centre environmental impact

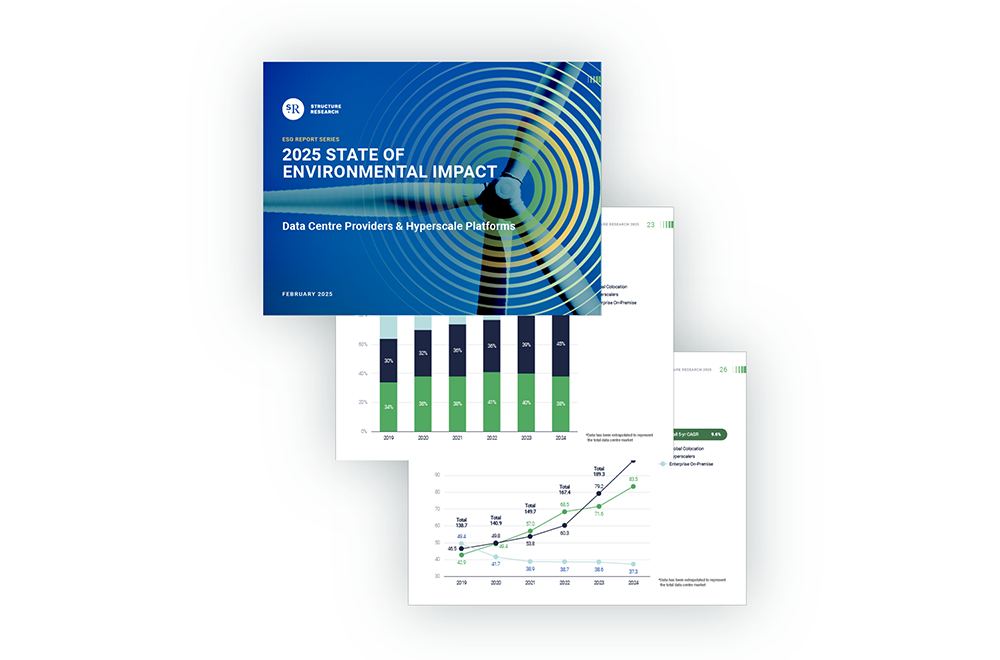

Structure Research has released its latest 2025 Environmental, Social, and Governance (ESG) Report, providing an in-depth look at the environmental footprint of data centre providers and hyperscale platforms.

The report captures sustainability metrics from 26 data centre operators and nine hyperscale cloud platforms, offering a unique snapshot into carbon emissions, energy consumption and water usage across the global infrastructure ecosystem.

The 2025 ESG Report finds that while data centre energy usage continues to rise - now accounting for more than 1.1% of global energy consumption - average carbon emissions per unit of energy consumed are trending downwards, driven by the growing adoption of renewable and carbon-free energy sources. Total energy usage increased from 178.5TWh in 2019 to 310.6TWh in 2024, while emissions intensity fell from 366.9mtCO2e/GWh to 312.7mtCO2e/GWh over the same period.

“Data centres are foundational to the modern digital economy, and that means they carry a growing environmental responsibility,” says Philbert Shih, Managing Director of Structure Research. “What this report shows is that while energy consumption continues to climb, providers are making meaningful progress in efficiency and renewable adoption. The industry is clearly moving in the right direction - but transparency and accountability will be critical as sustainability expectations evolve.”

Key findings from the report

Sustainability progress amid rising demand

· Energy usage by ESG Leaders grew 17.9% over the last five years, while renewable energy consumption increased by 27.9%.

· Hyperscalers now use renewable sources for approximately 91% of their total energy needs; data centre providers reached 62%.

· Carbon-free energy, including nuclear, is emerging as a key part of the data centre energy mix as power constraints grow in Tier 1 markets.

PUE and water efficiency improvements

· Average Power Usage Effectiveness (PUE) for data centre providers declined from 1.44 in 2019 to 1.38 in 2024, while hyperscale PUEs remained at an industry-leading 1.22.

· Data centre water consumption increased by 9.6% over five years, driven by demand for liquid cooling to support AI workloads and higher rack densities.

The report introduces the Structure Research Sustainability Quadrant (SRSQ), a benchmark framework ranking providers based on transparency, operational efficiency and renewable energy usage. The SRSQ aims to encourage better reporting standards and highlight leaders in environmental performance.

Structure Research’s analysis found that ESG reporting across the sector is becoming more common, though significant variation remains in the scope and depth of disclosures. The report emphasises the importance of transparency in environmental reporting and urges providers to include more granular, region-specific data in future disclosures.

The 2025 ESG Report is a tool for hyperscalers, colocation providers, enterprises and policymakers seeking to understand the environmental implications of data centre growth and how industry leaders are responding.

Carly Weller - 10 April 2025

Data Centre Infrastructure News & Trends

Data Centres

Infrastructure Management for Modern Data Centres

Innovations in Data Center Power and Cooling Solutions

Schneider unveils enhanced GenieEvo with 31.5kA fault rating

Schneider Electric has announced the launch of GenieEvo 31.5kA in the UK and Ireland.

GenieEvo is an air insulated medium voltage switchgear offering, with resilience, safety and reliability at its core.

Its higher fault current protection of 31.5kA, up from 25kA in previous iterations, means it reduces the risk of power outages by minimisig the dangers of equipment damage in the event of power overloads or short circuits

GenieEvo is digital in design and comes with Schneider Electric’s EcoCare membership services plan. It incorporates smart Internet of Things (IoT) sensors which transmit data, in real-time, to experts at Schneider Electric’s Connected Services Hub for monitoring and analysis. This enables condition-based monitoring and predictive maintenance which can cut the number of unplanned outages and ensure a more efficient approach to maintaining equipment.

It is particularly suited to those with heavy-duty electrical distribution needs such as Distribution Network Operators (DNOs), data centres and medium to large sites with significant energy requirements. These include industries such as oil and gas, mining and manufacturing, as well as large buildings including airports and hospitals.

GenieEvo key features include:

· A pure air design vacuum switchgear with a high fault current rating of 31.5kA for enhanced resilience, safety and reliability.

· Newly designed C-type bushings which are easy to install offering improved insulation, durability and thermal management.

· Innovative 2000A Busbar CTs ensuring high accuracy in metering and monitoring.

· A-FL switchgear front and side protection for users for Internal Arc Compliance (IAC).

· IoT sensors monitoring thermal, environmental and partial discharge data, 24/7, enabling condition-based and predictive maintenance.

· A compact design which can reduce space requirements by up to 40%. It comes with pre-engineered panels to meet individual requirements and can scale to meet future needs.

“To enable the energy transition, we need to integrate more energy sources to the distribution network, and this creates challenges, particularly for those with significant electricity demands,” says David Hall, Schneider Electric’s Vice President of Power Systems UK&I. “Organisations can’t afford power outages and must take control when it comes to resilience, safety and reliability. They should look at their switchgear as a priority. GenieEvo has been developed in response to market demands, allowing them to do just this.”

Schneider Electric will manufacture the GenieEvo at its Leeds site.

Carly Weller - 10 April 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Riello UPS expands Multi Power2 modular series

Critical power protection specialist, Riello UPS, has announced an extension to its ultra-high efficiency modular range Multi Power2.

The uninterruptible power supply manufacturer adds to its existing 500 kW MP2 UPS with a 300 kW version, along with a trio of 600 kW cabinets. The expansion increases the flexibility of the range, which is aimed at small to medium-sized data centres and other similarly mission critical applications.

The additional units deliver all the series’ key benefits, including ultra-high efficiency of 98.1% in online double conversion mode, risk-free ‘pay as you grow’ scalability, a robust design that eliminates any single point of failure, and hot-swappable 3U 67 kW power modules that ensure downtime-free maintenance.

Multi Power2 incorporates advanced silicon carbide (SiC) semiconductors that significantly reduce energy losses and heat generation, delivering data centre operators robust and reliable performance whilst lowering their operating costs, cooling requirements, and carbon emissions.

The extended MP2 range now incorporates:

• MP2 300 – up to five power modules for a maximum of 300 kW, features bottom cable entry and an integrated manual bypass switch;• MP2 500 – up to eight power modules for a maximum of 500 kW, features top cable entry, an integrated manual bypass switch, and air filters as standard;• MP2 600 – up to nine power modules for a maximum of 600 kW, available with or without switches and a choice of front-to-back or front-to-top ventilation.

Up to four UPS can be installed in parallel, meaning the MP2 can protect up to 2,400 kW in a single system.

As well as the expanded MP2, the complete Multi Power2 range also incorporates the popular Multi Power2 Scalable (M2S) innovation (which comes in 1,000 kW, 1,250 kW and 1,600 kW versions), and is designed with the needs of modern data centres in mind, as it can handle the rapid load fluctuations typically associated with AI load profiles. By connecting four M2S UPS in parallel, it can protect up to 6,400 kW.

Leo Craig, Managing Director of Riello UPS, comments, “With this exciting expansion of the Multi Power range, we are addressing the data centre industry’s growing focus on energy saving practices for a more sustainable future.

“By combining market-leading efficiency of 98.1% and flexibility in terms of power ratings and cabinets with a reduced carbon footprint and total cost of ownership, we are delivering data centres proven results without compromising on power continuity or performance.”

For more from Riello UPS, click here.

Simon Rowley - 4 April 2025

Data Centres

Innovations in Data Center Power and Cooling Solutions

Vertiv unveils scalable power solution, Vertiv PowerDirect Rack

Vertiv has announced the launch of the Vertiv PowerDirect Rack, a 1U high-density 50V DC power system shelf designed to bring resilience to even the most demanding AI and high-performance computing (HPC) environments.

This modular system scales up to 132kW per rack by integrating multiple power shelves, enabling expansion while minimising space requirements. Available globally, Vertiv PowerDirect Rack offers a complete infrastructure power solution, supporting two times the power capacity in the same footprint, compared to alternative solutions.

The Vertiv PowerDirect Rack is designed to help data centres maximise power efficiency and scale with ease. Built for Open Compute Project (OCP) ORv3 High Power Rack (HPR) environments, it delivers high-density power while reducing energy waste and simplifying operations. With flexible AC and HVDC input support, real-time monitoring and modular scalability, the power shelf enables seamless expansion to allow IT teams to meet growing power demands without increasing rack space or complexity, compared to traditional AC uninterruptible power supply (UPS) with separate rectification and power distribution, or lower density DC power shelves.

“Today’s data centres face increasing pressure to deliver more power in less space while supporting the rapid growth of AI and HPC applications,” says Kyle Keeper, Senior Vice President of the Power Business Unit at Vertiv. “Vertiv PowerDirect Rack addresses these challenges with a scalable, energy-efficient DC power design that equips operators with the flexibility to adapt to evolving workload demands and build future-ready infrastructure.”

Built for performance and adaptability, the Vertiv PowerDirect Rack delivers benefits that simplify power management and improve data centre energy efficiency. Key features include:

· Delivers up to 132kW per rack with N+N redundancy, enabling high-density deployments with a scalable, space-saving power architecture.

· Achieves 97.5% peak energy efficiency, minimising power waste, reducing cooling demands and lowering operating costs.

· Supports both AC and HVDC input, for seamless integration into diverse power infrastructures for future-ready data centres.

· Hot-swappable, modular design for uninterrupted operations and effortless scalability as power needs grow.

· Advanced power management and reliability, with built-in safeguards to maintain continuous performance and prevent disruptions.

Carly Weller - 1 April 2025

Data Centre Infrastructure News & Trends

Data Centres

Innovations in Data Center Power and Cooling Solutions

News

Schneider Electric appoints new Senior Vice President for Power business

Schneider Electric, an energy management and automation specialist, has appointed Pablo Ruiz Escribano as the new regional Senior Vice President (SVP) of its Secure Power and Data Centre Business in Europe.

Pablo has been with Schneider Electric for 18 years. Since he first joined as a Key Account Manager in 2007, Pablo has progressed through several leadership positions within the organisation, including roles as Power Products Channel Project Director, Vice President (VP) for Secure Power & Field Services in Iberia, and more recently, as VP for the Global Services Segment. His predecessor, Marc Garner, will move into a new global role as President of Schneider Electric’s Cloud & Service Providers (C&SP) Segment.

In his new role, Pablo will be tasked with leading Schneider Electric’s Secure Power and Data Centre Business across Europe, working with country and zone leaders in BeNe, CEEI, DACH, France, Iberia, Italy, Nordics and UKI to help customers solve the energy, infrastructure and sustainability challenges of AI.

With extensive experience in both regional and global roles, and a strong background in technical sales and customer relations, Pablo is well-equipped to assist Schneider Electric’s European customers as they navigate the opportunities presented by AI.

“I am delighted to begin my role as the new SVP for Schneider Electric’s Secure Power and Data Centre Business in Europe, and more so at such a transformative time for our industry,” says Pablo Ruiz Escribano. “With AI accelerating growth on multiple plains, there’s an unprecedented opportunity to enhance the efficiency, resiliency, and sustainability of the digital infrastructure landscape, and I look forward to working with our customers and partners to seize these opportunities and push the industry forward. I also want to extend my sincerest thanks to Marc Garner for his insights as I take on this new position and I wish him all the best in his next chapter.”

Pablo’s most recent role as Global Services Segment VP saw him responsible for successfully leading Schneider Electric’s Services business. Here, he effectively improved the integration of services strategies and actions within overall segment strategies and account plans. He has also coordinated multi-country, multi-technology strategic accounts throughout the adopt, expand and renew phases, as well as streamlining commercial activities across service zones, ensuring a unified services segment organisation with consistent account management.

As the new SVP for Secure Power and Data Centre Business Europe, Pablo will be responsible for delivering Schneider Electric’s end-to-end AI-ready data centre solutions across the region, helping customers to bend the energy curve of AI, and accelerating the decarbonisation of their large-scale energy and digital infrastructure systems.

He will also work with key stakeholders across Schneider Electric’s channel partner ecosystem including its EcoXpert, Alliance Partners, and its AI Ecosystem partners.

New Global C&SP President

Having served 20 years at Schneider Electric Marc Garner now takes up his first global role for the company as Cloud & Service Providers (C&SP) Segment President, where he will be responsible for helping the organisations’ AI cloud, colocation and hyperscale customers build-out and decarbonise their cloud and high-density AI data centre systems on a global scale.

Marc comments, "As data consumption soars and AI accelerates demand for high-density infrastructure, the data centre industry has a huge opportunity to lead the charge in efficiency and sustainability. It has been a fantastic opportunity to lead a team who has been able to achieve an unprecedented rate of growth for Schneider Electric here in Europe by helping our customers shape a resilient, efficient and AI-ready data centre landscape. I wish Pablo the best of luck in his new role as SVP for Secure Power and Data Centre Europe and extend a huge thank you to my team for their support during the last two years.”

Pankaj Sharma, EVP Secure Power & Data Centres and Global Services Businesses, adds, “At Schneider Electric, we are committed to driving the future of digital infrastructure through innovation, sustainability, and strategic leadership. Pablo’s extensive experience and deep industry expertise make him the ideal leader to continue advancing our Secure Power and Data Centre Business in Europe. His leadership will be instrumental in helping our customers navigate the opportunities AI presents.

“I would also like to extend our gratitude to Marc for his exceptional leadership in Europe, where he has played a crucial role in driving growth and expanding our capabilities. As he steps into his first global role as Cloud & Service Providers Segment President, we are confident that his vision and expertise will further strengthen Schneider Electric’s position in the digital infrastructure space.”

Both appointments will continue to report into Pankaj Sharma and are with immediate effect.

For more from Schneider Electric, click here.

Simon Rowley - 6 March 2025

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173