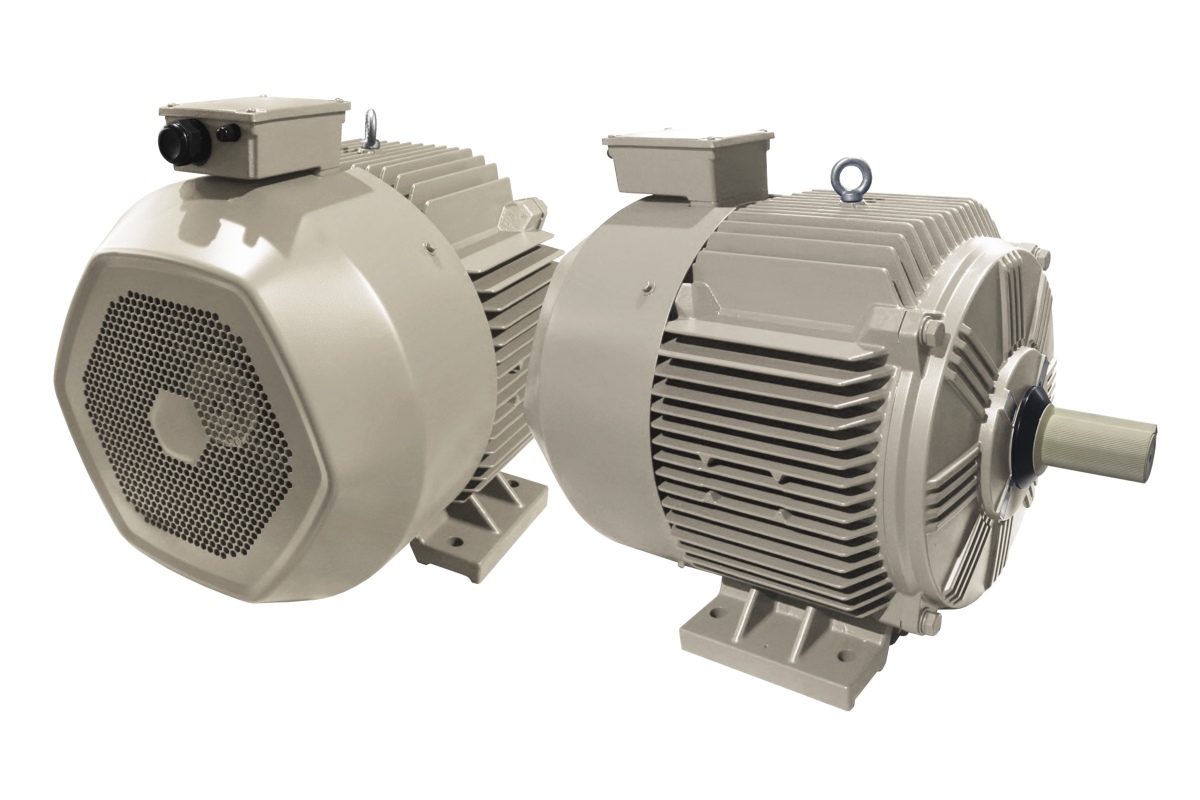

Wolong introduces efficient motors for DC cooling applications

Author: Joe Peck

Wolong Electric America, a developer of industrial motor and drive technology, has introduced its Permanent Magnet Direct Drive (PMDD) motors, highlighting their ability to improve energy efficiency and reduce heat generation in high-demand environments such as data centres.

Designed to operate without belts or sheaves, PMDD motors use a direct drive system that reduces mechanical complexity and common failure points, improving reliability and minimising maintenance requirements.

The approach should also reduce mechanical stress and radial load on bearings, contributing to a longer service life.

Lower heat output and energy use in data centres

At the core of each motor is a rare earth magnet design that delivers stronger magnetic fields in a compact form factor.

This aims to enable higher efficiency and cooler operation compared with traditional induction motors, which would be a key advantage in temperature-sensitive environments such as data centres, where controlling internal heat and power consumption are constant priorities.

The motors are operated via a variable frequency drive (VFD), enabling precise speed control, smooth acceleration and deceleration, and reduced electrical strain on supporting systems.

A 4:1 turndown ratio allows the motors to maintain torque and efficiency – including at low speeds – supporting variable airflow demands within cooling systems.

Wolong Electric says its PMDD motors can be integrated directly into fan assemblies, reducing overall system losses and eliminating inrush current at startup.

With reported efficiency improvements of around 20% over conventional induction motors, the design should contribute to measurable reductions in both energy use and waste heat.

Flexible configurations for critical environments

Wolong Electric says the PMDD motors can be tailored to specific applications, including data centre cooling systems, refineries, and OEM equipment such as heat exchangers.

The motors are designed to operate at lower temperatures and with reduced maintenance demands, supporting long-term reliability and stable thermal management across facility operations.

The company’s design approach hopes to enable easy integration with OEM and packaged system configurations, helping operators meet efficiency goals while aligning with evolving energy standards.