Product

Data Centres

Infrastructure

News

Product

UPS & Power Distribution

leagend UPS solution safeguards backup power supply

According to leagend Solutions, the backup power supply is the second heart of a data centre - and any issue that happens to it will cause huge economic losses or even disasters.

As a result, leagend's UPS battery management solution is a professional innovation exclusively developed for backup power applications such as data centres, telecom bases, and other applications seeking energy saving and renewable energy solutions. It guarantees the UPS batteries operate normally by monitoring and managing the key parameters of the batteries in real-time to ensure they supply stable power continuously under the accidence of a power outage.

Furthermore, it integrates with advanced technologies like data collection, data transfer and data processing to offer comprehensive monitoring, cloud storage, visualised data analyses and tailored services for customers.

Its capacity can be up to over 200 batteries with two different voltages simultaneously. In addition, leagend has integrated 5G and AI chips to the next-generation BMS.

– leagend Solutions has been specialising in researching and developing batteries technologies, battery testing technologies, battery monitoring and managing systems and solutions ever since the company’s establishment in 2014. Intelligence, precision, safety and low energy consumption are always the foundation and ideology of its technology research and development.

Until now, leagend Solutions has offered the following innovations: smart lead-acid battery testers, UPS battery monitoring solutions, lead-acid battery charger ODM solutions, Coulomb counter solutions, and more. The company’s battery products have been widely applied to multiple professional fields such as lead-acid battery manufacturing, data centre power supply chains, energy-saving, renewable energy, telecoms, and emergency backup power applications.

For more from leagend Solutions, click here.

Simon Rowley - 9 May 2025

Data Centres

News

Product

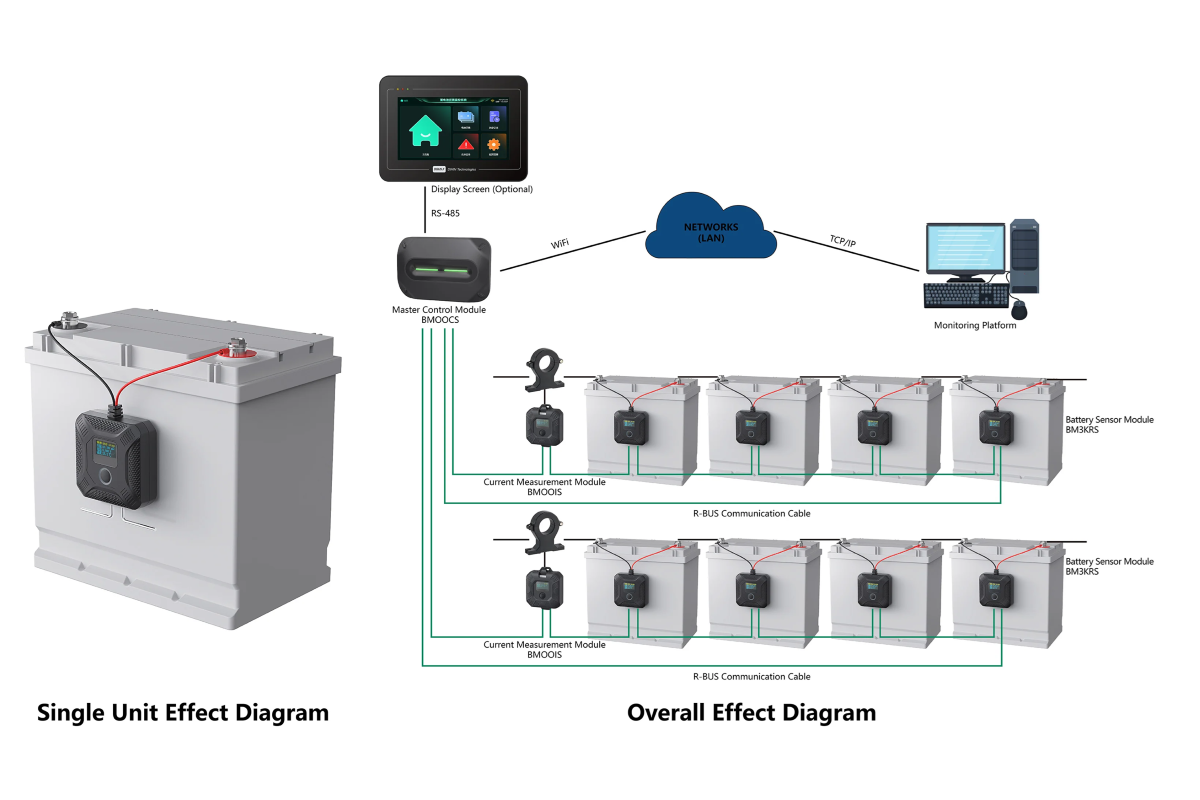

Battery remote monitoring to enhance security and efficiency

With security coming first for data centres, and efficiency improvement a crucial element, leagend's battery remote monitoring solution provides reliable battery monitoring for UPS batteries to ensure stable power supply in data centres to improve both security and efficiency.

It aims to ensure the efficient and safe operation of data centre backup batteries through real-time monitoring and management of battery pack status. It collects key data like battery voltage, internal resistance, current and temperature in real time, and transmits the data to the remote monitoring platform via 4G, Wi-Fi, Bluetooth or wired transmission. Through data analysis, it sends battery SoH (State of Health), lifespan prediction and failure warnings to help customers optimise battery usage, extend battery lifespan and ensure stable power supply.

The battery remote monitoring solution from leagend is developed for various applications like energy storages, electric vehicles, data centres, telecom bases and industrial equipment.

- leagend Solutions has been specialising in researching and developing batteries technologies, battery testing technologies, battery monitoring and managing systems and solutions ever since the company's establishment in 2014. Intelligence, precision, safety and low energy consumption are always the foundation and ideology of its technology research and development.

Until now, leagend Solutions has offered the following innovations: smart lead-acid battery testers, UPS battery monitoring solutions, lead-acid battery charger ODM solutions, Coulomb counter solutions, and more. The company's battery products have been widely applied to multiple professional fields such as lead-acid battery manufacturing, data centre power supply chains, energy-saving, renewable energy, telecoms, and emergency backup power applications.

To find out more, click here.

Simon Rowley - 6 May 2025

Data

Data Centres

Network Storage

News

Product

Innodisk launches SSD series for data centre applications

Innodisk, an industrial-grade flash storage provider, has announced the launch of its latest PCIe Gen5 SSD series, which is designed to meet the OCP Data Centre NVMe SSD spec v2.0 and the increasing demands of AI model training, big data analytics, and data-intensive environments.

The new series supports multiple form factors, including U.2, as well as EDSFF E1.S, E3.S, and the brand new E3.L for data centre applications, catering to the diverse needs of enterprise and data centre environments. Innodisk tells us that the new series marks a new chapter for the company in terms of further fulfilling enterprise demands.

The Innodisk PCIe Gen5 SSD, built with the latest PCIe Gen 5 x4 interface and NVMe 2.0 protocol, is designed to overcome the speed and latency limitations of traditional storage interfaces. With up to 128TB of high density NAND storage, it delivers speeds of up to 14GB/s (read) and 10GB/s (write), enabling lightning-fast data transfers for data-intensive applications.

Enterprise data centres managing large-scale storage deployments and multi-tiered environments often require out-of-band and batch management capabilities, which present growing challenges. Innodisk PCIe Gen5 SSD addresses these demands with NVMe-MI for streamlined SSD management and multi namespace support, ensuring scalable and efficient storage operations.

To ensure high quality and alignment with market trends, the PCIe Gen5 SSD aims to enhance integration with industry-leading data centre standards, such as OCP Data Centre NVMe SSD spec v2.0. Additionally, it is intended to be built for seamless integration with VMware, optimising compatibility with virtualisedenvironments and overall system performance.

Innodisk’s PCIe Gen5 SSD also features advanced security mechanisms, ensuring robust data protection and seamless integration. Secure Boot technology authenticates digital signatures during firmware updates, preventing unauthorised modifications and ensuring that only trusted firmware is executed.

Simon Rowley - 29 April 2025

Cooling

Data Centres

News

Product

Arteco launches direct-to-chip liquid cooling for data centres

Arteco, a provider of liquid cooling innovations, today announced its expansion into the data centre and electronics market with its Zitrec EC brand.

The company states that the new brand arrives at a "critical moment", citing the escalating computational demands of today’s powerful technologies - like Generative AI and Large Language Models - which produce unprecedented heat loads which are threatening system performance, energy efficiency, and hardware reliability in the event that improved thermal management solutions aren't implemented.

Zitrec EC, which is a versatile portfolio of Mono Propylene Glycol (MPG)-based, water-based and Mono Ethylene Glycol (MEG)-based formulations with OAT (Organic Additive Technology), is specifically designed to help tackle these challenges. This advanced range of direct-to-chip coolants is engineered to deliver exceptional thermal performance and energy efficiency, allowing components to operate at higher calculating power without the risk of overheating. Its advanced features provide long-lasting corrosion protection, which can extend equipment lifespan and provide a safeguard against downtime. Zitrec EC therefore simplifies hardware maintenance, Arteco says, while significantly lowering the total cost and complexity of thermal management systems.

“In this incredibly exciting era of AI and other technological advancements, we recognised a clear opportunity to combine our decades of cooling expertise with our relentless pursuit of innovation and sustainability, thereby empowering the digital infrastructure of tomorrow,” says Serge Lievens, Technology Manager at Arteco.

Alexandre Moireau, General Manager of Arteco, adds, “Our biggest strength in this new Zitrec EC chapter is the same unwavering commitment to product excellence and deep customer intimacy that established us as a trusted leader in the automotive world. In the data centre space, we will continue to proactively co-create with our customers, delivering tailored cooling solutions that meet, and exceed, their most demanding requirements. This is how we want to set new standards in thermal management in the data center and electronics market.”

As part of its broader sustainability strategy, Arteco has also announced the upcoming launch of a new bio-based MPG addition to its new Zitrec EC line. This new product complements the existing recycled MPG variant, underscores Arteco’s commitment to environmentally responsible innovation and offers the same product performance and quality as the other products in the Zitrec EC range.

For more from Arteco, click here.

Simon Rowley - 29 April 2025

Cooling

Data Centres

News

Product

Airedale launches AI cooling for data centres

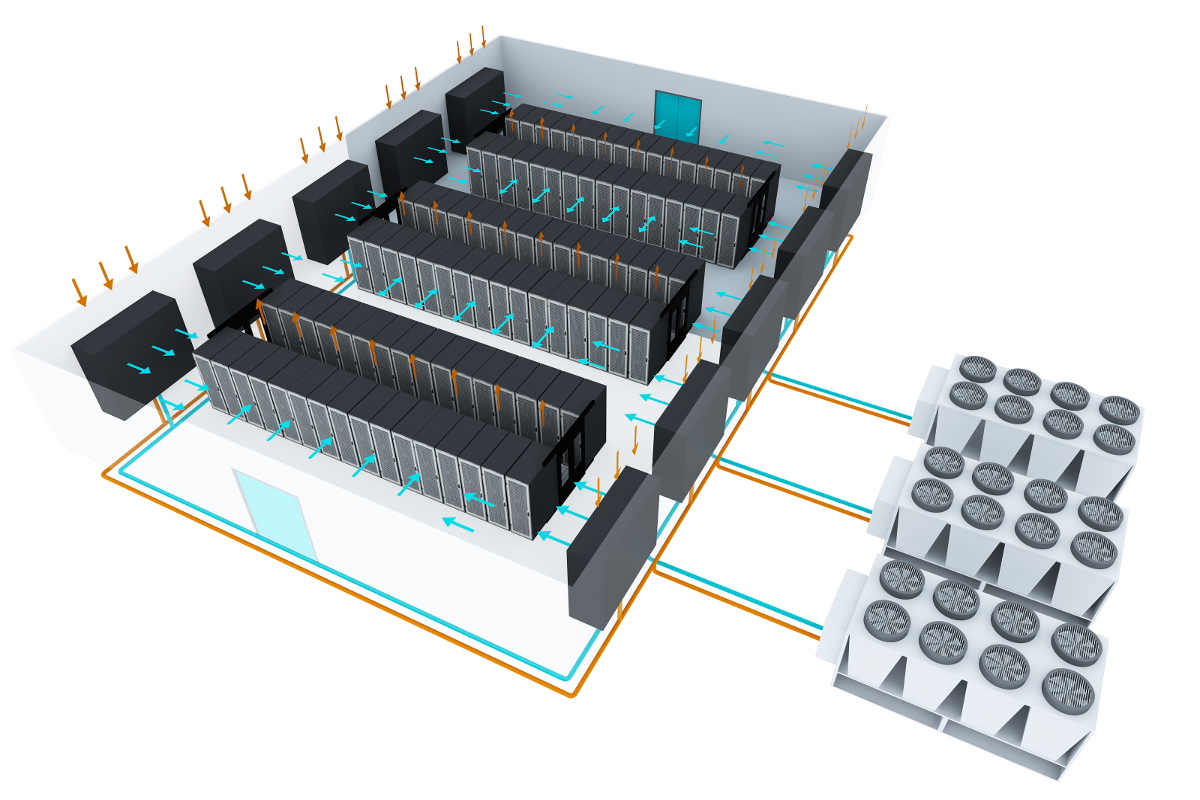

Airedale by Modine, a critical cooling specialist, is now offering an AI-enhanced version of its Cooling System Optimizer. The company believes that the release marks a tangible advancement in cooling and efficiency for high-density data centres.

Cooling AI delivers real-time adaptability, predictive intelligence and significant energy savings in response to global data centre industry demand for high-performance, high-efficiency control systems.

The patent-pending AI technology utilises a hybrid deep learning model, leveraging machine learning, neural networks and digital twins to maximise efficiency and reduce energy consumption, and enhance operational stability for hyperscale, colocation, and enterprise data centres.

The Cooling AI system continuously analyses cooling demands, optimises system operations and anticipates future conditions. It works as a supervisory layer to the Optimizer, allowing the building management system (BMS) to handle baseline monitoring functions, with its predictive AI model making proactive adjustments. This ensures the entire system learns from historical data and adheres to the physical laws governing HVAC behaviour.

Cooling AI can reduce energy consumption by up to 40%, improving power usage effectiveness (PUE) and driving sustainability gains. Chiller and fan performance is synchronised within the AI-driven data centre cooling control system, improving cooling efficiency and reducing energy use. Furthermore, the reduction in mechanical stress as a result of reduced compressor cycling can extend the equipment life cycle, as well as lower maintenance costs.

"As AI-driven computing accelerates, the demand for smarter, scalable and highly efficient cooling infrastructure has never been higher, and it isn't set to stop any time soon," says Reece Thomas, Controls General Manager at Airedale by Modine.

"Power densities rise and sustainability expectations will continue to increase, and data centres need cooling solutions that can evolve with them. By embedding AI directly into the control architecture, we are delivering more than just efficiency gains. We are enabling a future where cooling adapts in real time, anticipates challenges before they arise, and continuously improves over time. This is the next frontier in sustainable, high-performance data centre cooling."

The new system joins Airedale by Modine's broader suite of cooling technologies designed to meet the needs of the modern data centre. From high-efficiency chillers, precision cooling units and modular fan walls to intelligent controls and airflow management systems, Airedale's solutions are designed to optimise efficiency, reduce energy consumption and enable scalable cooling across the entire data centre ecosystem.

Cooling AI is available as a new system or retrofitted to an existing Airedale by Modine Cooling System Optimizer.

For more from Airedale by Modine, click here.

Simon Rowley - 25 April 2025

Data Centres

Infrastructure

News

Product

UPS & Power Distribution

Riello UPS expands Multi Power2 modular series

Critical power protection specialist, Riello UPS, has announced an extension to its ultra-high efficiency modular range Multi Power2.

The uninterruptible power supply manufacturer adds to its existing 500 kW MP2 UPS with a 300 kW version, along with a trio of 600 kW cabinets. The expansion increases the flexibility of the range, which is aimed at small to medium-sized data centres and other similarly mission critical applications.

The additional units deliver all the series’ key benefits, including ultra-high efficiency of 98.1% in online double conversion mode, risk-free ‘pay as you grow’ scalability, a robust design that eliminates any single point of failure, and hot-swappable 3U 67 kW power modules that ensure downtime-free maintenance.

Multi Power2 incorporates advanced silicon carbide (SiC) semiconductors that significantly reduce energy losses and heat generation, delivering data centre operators robust and reliable performance whilst lowering their operating costs, cooling requirements, and carbon emissions.

The extended MP2 range now incorporates:

• MP2 300 – up to five power modules for a maximum of 300 kW, features bottom cable entry and an integrated manual bypass switch;• MP2 500 – up to eight power modules for a maximum of 500 kW, features top cable entry, an integrated manual bypass switch, and air filters as standard;• MP2 600 – up to nine power modules for a maximum of 600 kW, available with or without switches and a choice of front-to-back or front-to-top ventilation.

Up to four UPS can be installed in parallel, meaning the MP2 can protect up to 2,400 kW in a single system.

As well as the expanded MP2, the complete Multi Power2 range also incorporates the popular Multi Power2 Scalable (M2S) innovation (which comes in 1,000 kW, 1,250 kW and 1,600 kW versions), and is designed with the needs of modern data centres in mind, as it can handle the rapid load fluctuations typically associated with AI load profiles. By connecting four M2S UPS in parallel, it can protect up to 6,400 kW.

Leo Craig, Managing Director of Riello UPS, comments, “With this exciting expansion of the Multi Power range, we are addressing the data centre industry’s growing focus on energy saving practices for a more sustainable future.

“By combining market-leading efficiency of 98.1% and flexibility in terms of power ratings and cabinets with a reduced carbon footprint and total cost of ownership, we are delivering data centres proven results without compromising on power continuity or performance.”

For more from Riello UPS, click here.

Simon Rowley - 4 April 2025

Networking

News

Product

EXFO introduces new line of 'always-on' testers

EXFO, a network test, monitoring, and analytics expert, has introduced a new series of always mobile-connected testers designed to increase field efficiency, compliance, and collaboration when deploying and maintaining fibre networks.

The FTB Lite 700 series of OTDRs (optical time domain reflectometers), with seamless connectivity to EXFO’s Exchange cloud-based solution, was revealed at the FTTH Conference 2025 in Amsterdam earlier this week.

“EXFO’s innovative FTB Lite 700 series is not just another test platform - it’s a game-changing tool built to enhance efficiency and performance in the field,” says Etienne Gagnon, Senior Vice President, Test & Measurement at EXFO. “Given the expansive growth in fibre networks as well as data centre proliferation, driven by AI applications, it’s imperative for deployments to be completed right the first time, and operators can now see their entire operation unfold in real time.”

Automated access to comprehensive live data enabled by EXFO Exchange means being able to perform analytics and extract insights for better informed decision-making and planning, EXFO says, which in turn can accelerate project timelines. Real-time job tracking and reporting ensures that methods of procedure are adhered to for compliance with testing standards, while reducing errors and administrative time.

Collaboration is enhanced given ease of connecting with team members in the office, on the road, or on-site in the field. Real-time data sharing, automated uploads, and cloud-based reporting all contribute to seamless and efficient teamwork. EXFO is an expert in OTDRs, and whether technicians are experienced or new to the role, EXFO believes they can excel at their jobs with user-friendly FTB Lite 700 series OTDRs for faster task completion and faster time to payment.

Simon Rowley - 28 March 2025

Cooling

Data Centres

News

Product

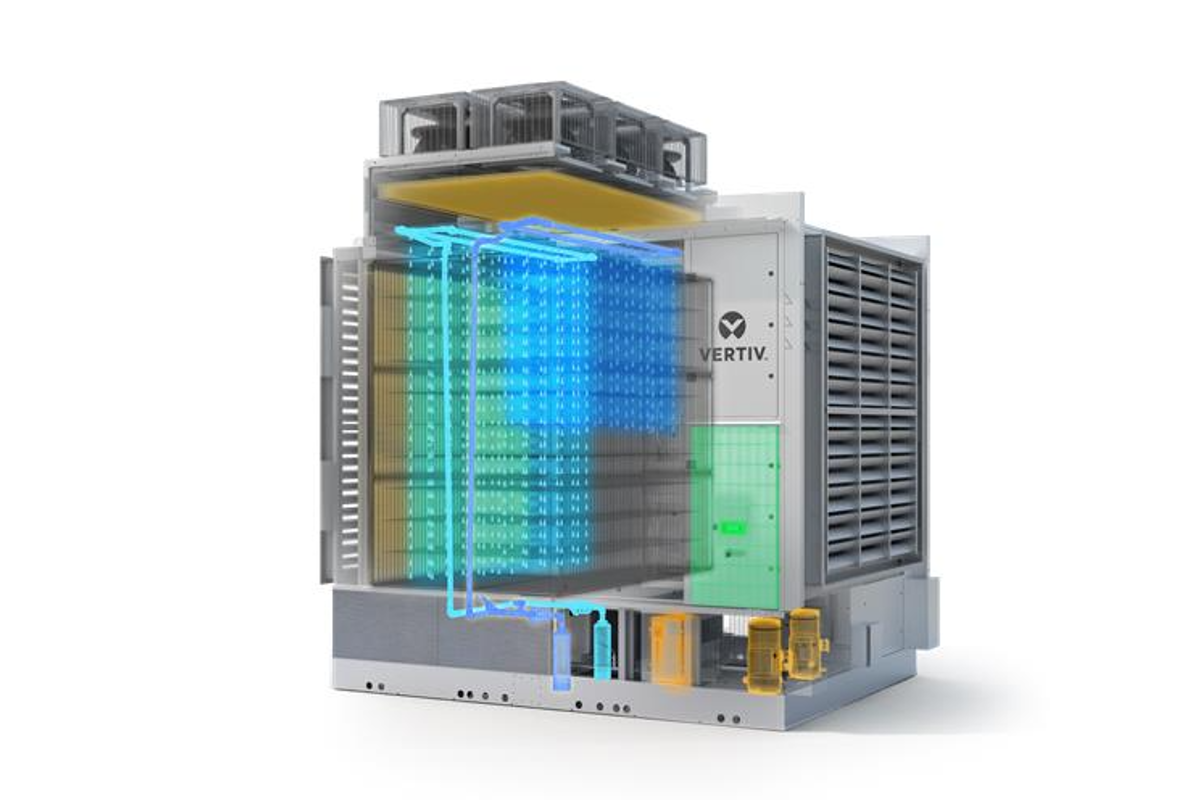

Vertiv launches free cooling unit for data centres

Vertiv, a global provider of critical digital infrastructure and continuity products, has announced a significant upgrade of its thermal management product portfolio with the introduction of the next-gen Vertiv Liebert EFC free cooling unit with low-GWP (Global Warming Potential) refrigerant.

It is designed to meet stringent environmental standards for data centre applications, including colocation and cloud services, and is now available across Europe, Middle East and Africa (EMEA) with capacities ranging from 150 to 450 kW.

Vertiv Liebert EFC combines the capabilities of indirect air-to-air heat exchange and evaporative cooling principles in a single unit. The innovative patented polymer heat exchanger and the new low-GWP inverter driven compressor technology significantly enhance annual efficiency by up to 19% compared to previous technologies, allowing a pPUE (partial Power Usage Effectiveness) as low as 1.05.

One of the standout benefits of the Liebert EFC is its extreme flexibility, Vertiv tells us. Based on onsite-specific conditions, a live toggling control feature allows users to seamlessly and securely reduce the use of critical resources like power or water via software controls, to leverage the free cooling mode. This flexibility empowers data centre owners to reduce their climate impact while enabling continuous cooling, regardless of site-specific resources. Models are available with full direct expansion (DX) back-up with a remote condenser, to supply the entire cooling capacity without any water requirements - offering full water independence, without impacting reliability.

"As businesses prioritise sustainability strategies, customers are increasingly seeking innovative cooling solutions that reduce resource consumption while offering operational flexibility and resilience," states Sam Bainborough, Vice President, Thermal Business EMEA at Vertiv. "The Liebert EFC, with its game-changing and patented technology, addresses these needs with a flexible system that delivers an entirely new experience for the customer, maximising time using free cooling and leveraging the natural power of evaporation.”

The new Liebert EFC complies with current global regulations and bans (EU F-Gas regulation 2024/573, and IPCC AR4), offering a turnkey solution engineered for future scalability, easy maintenance, and durability. The polymer design offers improved corrosion resistance and also allows a wider range of water qualities during operation when compared to an aluminium heat exchanger.

At the core of this innovation is Vertiv Liebert iCOM and its control algorithms, which manage automatic transitions between the most suitable working modes, enabling use of the preferred cooling source. The controls also enable seamless coordination of units, allowing them to function as a unified system, enhancing cooling continuity and reliability without the need for an additional plant management system.

For more from Vertiv, click here.

Simon Rowley - 25 March 2025

Cooling

Data Centres

News

Product

Johnson Controls launches air-cooled chillers in Europe

Johnson Controls, an expert in smart, safe, healthy and sustainable buildings, has expanded the availability of its YORK range of YVAM air-cooled magnetic bearing chillers to Europe to meet the growing demand in the data centre industry.

As the European data centre market experiences significant growth driven by AI and cloud computing, the YVAM is a crucial thermal management technology for hyperscale and colocation facilities, Johnson Controls tells us. Designed to accelerate deployment with an innovative, scalable and consistent platform, the YVAM also plays a role in ensuring compliance with the new European Union policy on energy efficiency and water conservation.

"As data storage demand rises and chip density increases, data centres face increasing challenges with cooling technologies, including broader temperature ranges, reduced energy and water use, noise reduction and limited space," says Johnson Controls President of Data Centre Solutions, Todd Grabowski. "At Johnson Controls, we work with our customers to offer solutions that enable data centres to scale rapidly, operate efficiently, minimise resource use and maintain reliability in a quickly changing landscape."

The YORK YVAM chiller consumes 40% less power annually while still delivering the same cooling capacity as other available products. In addition, YVAM offers the widest operating range, allowing for chiller operation from -29°C up to +55°C ambient temperature while producing chilled water temperatures between +15°C up to 30°C. This allows complete flexibility to use the same cooling infrastructure regardless of the cooling technology ranging from cold air aisles to immersion cooling or direct liquid cooling.

Further features and benefits include:

• Operates with zero water use on site, supporting the growing importance of water usage effectiveness (WUE) and the conservation of water.• Utilises ultra-low Global Warming Potential (GWP) refrigerant.• Leverages Johnson Controls proprietary magnetic-bearing technology, variable-speed drives and active front-end technology to maximise efficiency while eliminating the need for free cooling coils.• Produces notably less sound than screw chillers, operating at just 65 dBA at 10 metres - equivalent to the noise level of background music at a restaurant.• The lubrication-free design further simplifies the system by eliminating complex subsystems and reducing maintenance costs.• To ensure uninterrupted operations, the YVAM incorporates Quick Start technology with an integral emergency power management system, enabling the chiller to return to full load in as little as three minutes after a power interruption.• The YVAM is designed in-house and built using flagship York technologies.• It's designed to be a flexible platform that allows for easy inspection and service.

"With its innovative design and industry-leading efficiency, YVAM is set to redefine thermal management in data centres across the region,” Todd continues. “We’ve already seen great success for this technology in the North American market and we’re excited to partner with our European customers as the AI and data centre demand rapidly develops.”

Johnson Controls offers a wide range of air-cooled and water-cooled chillers as well as air handling units, all designed to meet the needs of hyperscale and colocation customers. These products are supported by a comprehensive suite of fire, safety, building automation and digitally connected services.

In June 2024, Johnson Controls launched a dedicated Global Data Centre Solutions organisation to address the industry's rapid growth. Since then, the company has boosted capacity in key regions to meet market demand and reduce lead times. This specialised organisation allows Johnson Controls to provide consistent, high-quality, centralised solutions across the globe, while also adapting to the unique needs of North America, EMEA and APAC, ensuring smooth and reliable support for data centre operators worldwide.

For more from Johnson Controls, click here.

Simon Rowley - 14 March 2025

Data Centres

News

Product

EnerSys advances data centre backup power management

EnerSys, a provider of stored energy products for industrial applications, has announced the integration of advanced embedded technology into its DataSafe Thin Plate Pure Lead (TPPL) batteries, enhancing backup power management for data centres. This development enables real-time battery monitoring, optimising performance and reliability in environments where continuous power is critical.

As global data centre power demand continues to rise, driven by sectors like AI and cryptocurrencies, the International Energy Agency (IEA) projects that by 2026, demand could double, reaching 1,000 terawatt-hours (TWh) - which is roughly equivalent to Japan’s total yearly electricity consumption today. With this growing demand, data centres face mounting pressure to improve backup power systems to ensure operational continuity.

EnerSys technology addresses these challenges by embedding monitoring technology directly into lead-acid batteries. The technology tracks key battery parameters such as voltage and temperature, enabling data centre operators to perform proactive maintenance and reduce battery related downtime. It also integrates with the EnVision Connect system monitor, offering data-driven insights for better performance and operational control.

"We’re proud to be at the forefront of transforming backup power management for data centres," says Paul Willougby, Director, Data Centre EMEA at EnerSys. "As data centre power requirements grow, our technology offers operators enhanced visibility and control, ultimately improving reliability and reducing maintenance costs. The integration of embedded intelligence within the battery system is a game-changer for ensuring operational continuity in high-demand environments."

A European data centre recently deployed 260 DataSafe batteries with the embedded technology ahead of a major international sporting event to enhance backup power monitoring. By integrating this technology with the EnVision Connect system monitor, the data centre was able to achieve more frequent battery status updates, reducing blind spots and improving its ability to proactively address issues. This integration also led to a reduction in emergency maintenance interventions, helping lower costs while improving compliance with power resilience requirements. Additionally, the data centre gained better operational control, which helped reduce risks associated with backup power failure.

This deployment highlights how EnerSys’ technology, in conjunction with the EnVision Connect system monitor, is striving to set a new benchmark for data centre backup power monitoring, ensuring efficiency, reliability, and operational security.

Simon Rowley - 14 March 2025

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173