Smart power management in buildings and data centres

Author: Beatrice

By Matthias Gerber, Market Manager LAN Cabling, Reichle & De Massari and Carsten Ludwig, Market Manager DCr, Reichle & De-Massari AG

Regulations regarding energy savings required to reach climate goals are becoming increasingly stringent. Recent research from Deloitte shows that buildings are currently responsible for 30-40% of all urban emissions. This must be reduced by 80-90% in order to achieve COP21 targets by 2050. Using intelligence in digital buildings is essential to achieving this. However, according to the BSRIA ‘Trends in the global structured cabling markets’ report (April 2022), no more than 1-2% of buildings deploy cutting edge smart technologies. Buildings everywhere need to be renovated and managed smarter.

For buildings to become more energy efficient, they need to become smarter. All energy needs to be used wisely and not wasted on anything that might be considered unnecessary – an intelligent building connects all devices, automates processes and leverages data to improve performance. Intelligent buildings continuously learn, adapt and respond. This can highlight areas where energy usage is being wasted and help find solutions so that HVAC systems, smart lighting, and other in-building systems (sensors) reduce their energy consumption. This approach makes it possible to better manage resources and utilities.

Sensors provide the foundation for intelligent buildings. Today, almost every device can function as a sensor. In the past, every system would have its own sensors, but these didn’t exchange data or interact. In the smart home environment, we’re seeing something similar today: numerous ‘island’ solutions, with each manufacturer using their own platform and integrated devices. However, it makes more sense to use an existing sensor in an installed device, instead of adding the same type of sensor to multiple devices.

Convergence is now allowing information from individual devices to be used to optimise the performance of other devices and the system as a whole. The converged network brings IT and OT together. Security protocols can run from enterprise servers, removing the need for protection of individual networks. One single interface and dashboard can be used to manage and control lighting, heating, ventilation and security.

An ‘all-IP’ network allows all devices to use one common language, supporting integration and optimisation. All building technology and building management devices communicate in the same way, without barriers, over Ethernet/Internet Protocol (Ethernet/IP), with the LAN providing the basis for physical communication. IP-based convergence enables sharing of resources across applications and brings standardisation, availability, reliability and support for new deployments.

The ‘digital ceiling’ concept supports ‘All over IP’ implementations. The data network and PoE are extended through an entire building’s ceiling, making it possible to connect building automation devices within defined zones with pre-installed overhead connecting points. The ‘digital ceiling’ will increasingly provide services that building occupants and managers are going to need in the near future and for years to come, enhancing user experience while reducing energy usage, making maintenance and adding new devices faster and easier, lowering installation and device costs, and increasing layout flexibility.

A closer look at energy management in the data centre

Data centres are responsible for some 2% of greenhouse gas emissions, which is almost the same as the entire global airline industry. For some time, designers and operators have been using the Greenhouse Gas Protocol, developed by businesses, NGOs, government bodies and other stakeholders to evaluate their supply chain and performance. Similar initiatives such as the recently published Climate Neutral Data Centre Pact, initiated by CISPE, point the way ahead for the data centre industry.

Besides security, energy and (especially) cooling are key talking points in the data centre industry. Of every kilowatt used in the DC, the biggest portion is turned into heat. You can improve power efficiency by using more efficient equipment and thereby reduce heat production, but there is always some excess heat. The question is how to deal with this heat in a way that results in the least environmental harm.

One approach is using liquid-cooled PCBs so that components on the circuit board don’t heat up and, therefore, don’t pass on heat to the chassis or rack. This uses dedicated horizontal pre-terminated rack boxes which have connections for fibre and copper, cooling fluid and power. However, you will need specialised hardware for this, that will be difficult to swap out when you want to make changes. Cooling precisely at source is very efficient. By cooling individual components, heat is reduced, and their operational lifetime improves. This approach is complicated and requires some preparation based on the needs of individual applications, the nature of the business the hardware is used for, and the business case.

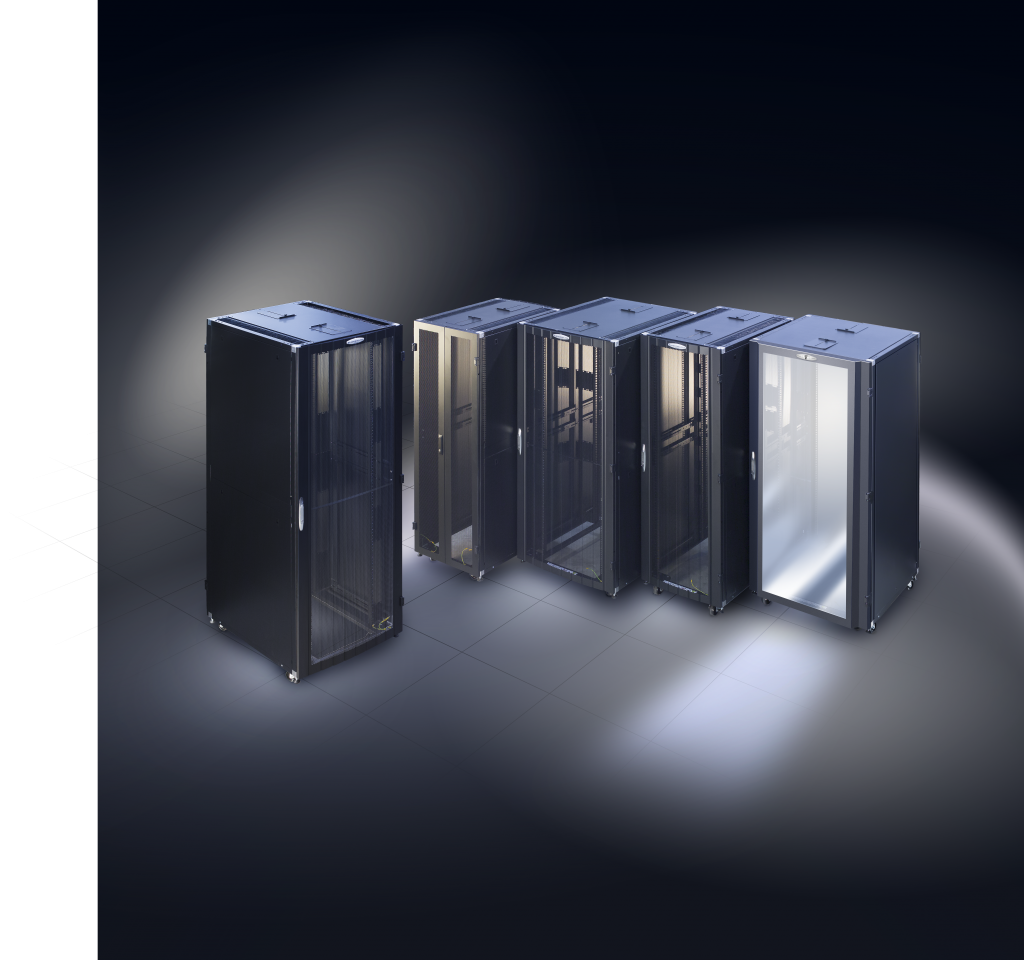

Another way of dealing with heat is distributing the components across a wider area. Concentrating as many racks as possible in a huge data centre may bring economies of scale and some practical benefits, but it also concentrates a vast amount of heat production in one space – and isn’t always technically necessary. When hardware becomes outdated or a new user needs to be connected, edge hardware could be moved from, for example, a mid-sized enterprise customer location to a hyperscale facility. Later, it might even be moved from the mid-sized location to an even smaller private location.

Intelligent architecture that carefully considers hot and cold aisles is another approach. The less room you need to cool, the less energy you need. Bad examples can be found, with huge rooms being cooled, even though they house just one small containment in a corner. The airflow is a mess in such a case, and the use of energy is extremely inefficient. Cooled air needs to be as close to the equipment as possible and should only cool targeted areas.

Wherever DCIM software is used, the company sees power and cooling monitoring engaged as a minimum. In fact, often these are the ONLY monitored KPIs. Not only does this help avoid energy waste but it also improves stability of the system, avoiding malfunctions or even fires. If connectivity doesn’t work, performance is harmed, but there’s no physical danger to the system or to people. However, not knowing the status of power and cooling can lead to real damage.

It’s also interesting to consider the true price of all the data we’re generating. Many people are wondering why we’re spending so much power on storing. Some don’t realise how much power their phones, tablet and computers use, and how much energy it requires to transport and store all this data. Maybe it would be good if we thought about the environment every time we posted something online!