Cooling

Cooling

Data Centres

News

Product

STULZ introduces CyberAir Mini DX air conditioning unit

STULZ, a mission critical air conditioning specialist, has announced the introduction of its CyberAir Mini DX range of space saving innovations for small and medium sized heat loads. Available from January 2025, the CyberAir Mini DX complements the highly successful CyberAir Mini CW range, and together, they will replace the company’s MiniSpace series.

With the CyberAir Mini DX, STULTZ aims to build on the success of its CyberAir Mini CW, which was introduced in 2021 and is available in four sizes with cooling capacities between 8.9kW and 34.7kW. Built using state-of-the-art components, the CyberAir Mini DX is a compact and efficient precision direct expansion air conditioning system that delivers effective climate control in server rooms and telecommunication closets. It is ideal for businesses seeking to safeguard sensitive IT infrastructure through precise temperature control, while at the same time minimising operating costs.

The CyberAir Mini DX is available in three sizes, with outputs from 5.9kW to 22.7kW - and to offer the most appropriate option for the widest variety of applications, each device can be configured with a choice of five different cooling systems. These include two air-cooled direct evaporation systems (A/AS), a water-cooled direct evaporation system (G), a chilled water system with redundant air cooling (ACW) and a hybrid free cooling system (GE).

To further enhance the level of customer choice, the CyberAir Mini DX can operate with four different varieties of refrigerant. Alongside R410A and R407C options, STULZ is continuing its mission to provide the most sustainable air conditioning systems possible by offering R513A and R454C low Global Warming Potential (GWP) refrigerants.

"With our low-GWP R513A (GWP 631) and R454C (GWP 148) options, we are able to improve energy efficiency, reduce environmental impact and ensure regulatory compliance," explains Norbert Wenk, Head of Global Product Management at STULZ. "This is important, considering the European Union’s (EU) F-Gas Regulation, which targets a two-thirds reduction in the EU’s fluorinated greenhouse gas emissions by 2030 compared to 2014 levels. As one of the first manufacturers of air conditioning units to incorporate the use of R513A in its technology, we remain committed to extending the use of low-GWP refrigerants throughout our portfolio."

Safety is also a significant design consideration, and when using flammable refrigerants such as R454C, STULZ offers the necessary safety features as part of a complete system. In addition, CyberAir Mini DX models are available as upflow or downflow versions, with flexible intake and discharge options, while exceptional energy efficiency is achieved using electronically commutated (EC) fans which operate efficiently at partial loads and have low noise levels.

STULZ places a strong emphasis on user-friendliness, and thanks to an optimised device design, CyberAir Mini DX models are easy to maintain and are equipped with the STULZ E² control system. With a touchscreen display for intuitive operation and quick parameter configuration, functions such as redundancy management, cross-machine parallel operation, standby management with emergency operation and connection to a building management system (BMS) are also possible through the E² controller.

"As part of our programme of continual innovation, we are delighted with the CyberAir Mini DX, which successfully combines operational safety, scalability, durability and reliability," Norbert continues. "We will be taking orders from the start of 2025 and customers, planners and refrigeration contractors can reach out to their STULZ customer advisor at any time for detailed information and personalised advice."

For more from STULZ, click here.

Simon Rowley - 13 December 2024

Cooling

Data Centres

News

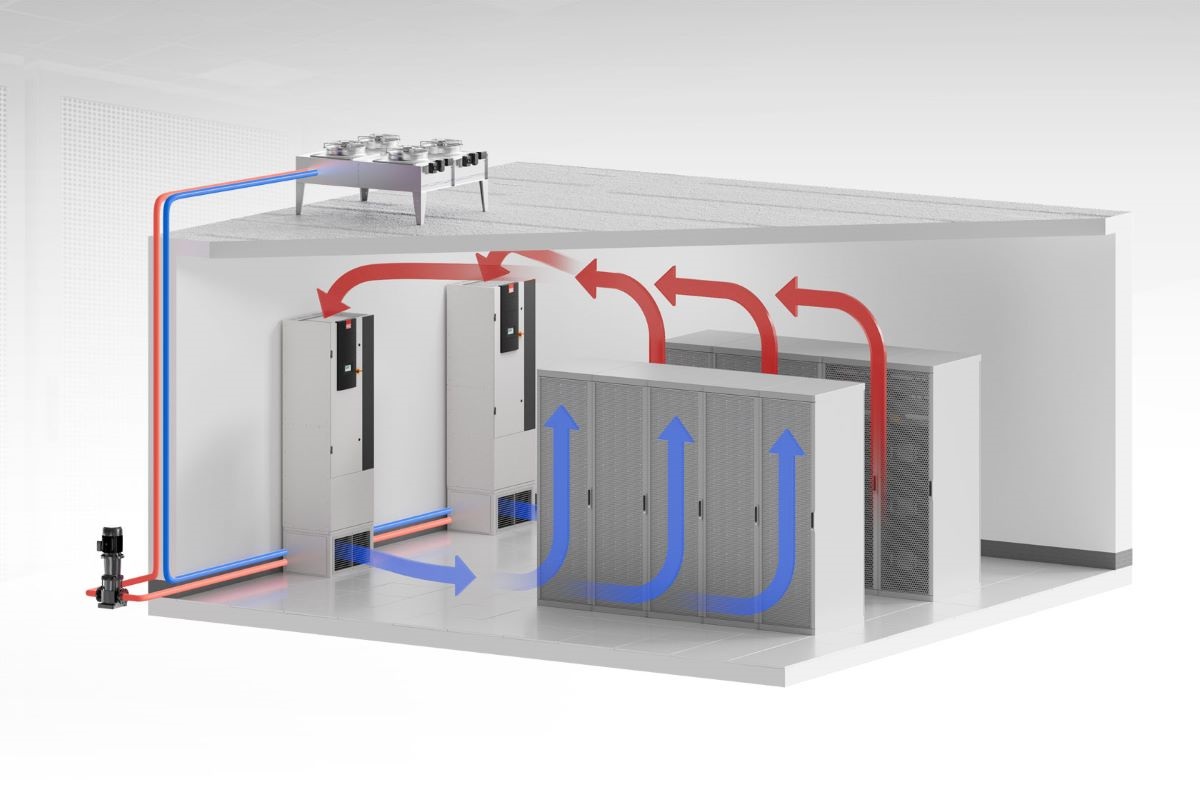

Lennox launches new business to support data centre industry

Lennox, a provider of energy-efficient climate control solutions, is launching a new business to address the specific cooling challenges of the data centre industry. Lennox Data Centre Solutions is a standalone business that will provide innovative, sustainable cooling solutions and services directly to the data centre market across Europe, the Middle East and Africa.

The global data centre market looks set to grow at around 9.1% CAGR through to 2030. In Europe alone, market studies estimate the current data centre capacity at 12,23GW, expanding at a rate of 600-700 facilities a year.

The heat generated by these new data centres will require efficient and effective processing, be that through heat rejection, heat reuse or a combination of the two. Today’s demanding energy and performance standards require heat rejection products that offer precision, efficiency and reliability.A natural extension of its existing expertise, Lennox Data Centre Solutions intends to bring Lennox's high level of product and service excellence to customers in the data centre market.

“Our experience has led us to a position where we understand that data centre solutions, especially for cooling processes, are bespoke from project to project,” says Matt Evans, CEO of Lennox Data Centre Solutions. “Backed by renewed investment and focus, the business will lead with an engineering consultancy approach to the design of data centre heat-rejection solutions. We aim to treat every project on individual merit, working closely with customers to create the optimal solution based on our full end-to-end product suite.”

Lennox Data Centre Solutions has deep knowledge in data centre design and build excellence. This arrives courtesy of its existing experience in this sector as part of Lennox, bolstered by a number of strategic new recruits with proven expertise in data centre cooling solutions.

The ability to tap into the comprehensive resources of Lennox EMEA is significant. With manufacturing facilities in Lyon and Dijon in France, Burgos in Spain, and fully certified Eurovent test facilities to match, each plant features advanced production capabilities staffed by highly skilled professionals to ensure quality and reliability.

Lennox Data Centre Solutions is offering a full portfolio of cooling solutions for data centres. Adapting some products from the existing Lennox portfolio, others have been designed and manufactured from the ground up. The range spans close control units (CCU’s), computer room air handler (CRAH) units, fan wall units (FWU), cooling distribution units (CDUs), chillers, and both adiabatic and conventional dry coolers.With the new business, Lennox can call upon a team of over 100 in-house technical engineers supporting product commissioning, service and maintenance across Europe alone. With the largest team of its type in the region, data centres can expect seamless integration, installation and support for their bespoke projects.

Ultimately, the goal is to become the preferred partner for enterprise, colocation and hyperscale data centre operators seeking efficient, effective and sustainable data centre cooling solutions. This ambition aligns with Lennox’s long-standing commitment to pushing the boundaries of innovation and efficiency.

Lennox Data Centre Solutions is backing its expectations for rapid growth with an aggressive recruitment campaign that will further build the EMEA team over coming months. Alongside its direct support for data centres, the new business will also look to provide support through an exclusive partner network of consultants and system integrators.

Simon Rowley - 13 November 2024

Cooling

Data Centres

News

Projects

Contingency cooling for Birmingham hospital data centre

ICS Cool Energy, a specialist temperature control solutions company, has delivered a comfort and process temperature control solution for a major hospital in Birmingham.

The hospital required an additional 80 kW of cooling capacity for comfort cooling in one of its patient wards, as well as a contingency cooling system for its data centre, which houses sensitive patient and operational data. Both systems were provided as long-term hires, with ICS Cool Energy’s i-Chillers serving as the backbone of these temperature control applications.

The hospital approached ICS Cool Energy with two key cooling needs. Firstly, it required a reliable and cost-effective system to deliver air-conditioning for patients’ comfort. Secondly, and more critically, it needed an on-site contingency cooling solution for its data centre.

Previously, the hospital relied on external providers. No on-site contingency system meant that in the event of a failure, it had to call in to deliver and install backup equipment. This reactive approach posed a significant risk, as every minute is critical when it comes to data centre cooling. Any delay in restoring cooling could lead to irreversible data loss.

Following a comprehensive site assessment and analysis of the hospital’s requirements, ICS Cool Energy’s sales engineers proposed a solution to meet both needs:

1. A process-grade 80 kW i-Chiller to provide comfort cooling for the patient ward. This system was delivered under a rolling 12-month hire agreement, offering the hospital long-term flexibility without capital expenditure. The chiller ensures stable and reliable temperature control, creating a comfortable environment for both patients and staff.

2. To safeguard the hospital’s data centre, ICS Cool Energy installed a 160 kW i-Chiller alongside multiple internal air handling units. This backup system is always on standby and ready to take over should the primary cooling system fail. With this contingency solution in place, the hospital no longer has to rely on external emergency cooling support, significantly reducing the risk of data loss.

Grant Spittle, Sales Engineer, ICS Cool Energy, comments, “Had the hospital maintained its previous arrangement of calling in external help during a failure, the data centre could have been severely compromised. Without backup equipment on-site, any failure in the regular cooling system could have resulted in the loss of vital patient and operational data. The new system minimises this risk and ensures continuity and data protection.”

The hospital now benefits from two reliable air-conditioning and cooling systems on long-term hire. The i-Chillers provide consistent comfort cooling in the patient ward, contributing to overall patient well-being.

Meanwhile, the contingency cooling system helps keeping the hospital’s data centre operating and critical data protected. The on-site backup is ready for immediate activation in the event of a failure, preventing potential data loss and avoiding severe financial and operational consequences.

This project highlights ICS Cool Energy’s expertise in delivering efficient, reliable, and cost-effective solutions that give customers peace of mind and operational flexibility.

For more from ICS Cool Energy, click here.

Simon Rowley - 28 October 2024

Cooling

Data Centres

News

Power & Cooling

Schneider Electric acquires liquid cooling company

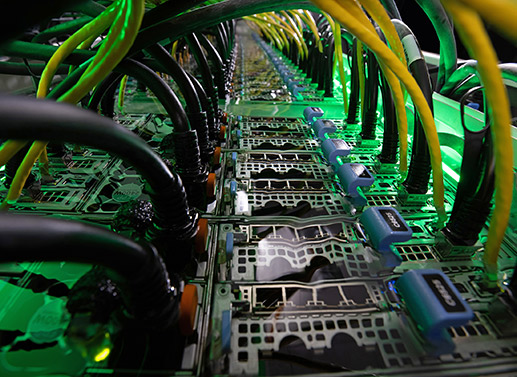

Schneider Electric has announced that it has signed an agreement to acquire a controlling interest in Motivair Corporation, a company that specialises in liquid cooling and advanced thermal management solutions for high performance computing systems.

The advent of Generative-AI and the introduction of Large Language Models (LLMs) have been additional catalysts driving enhanced power needs to support increased digitisation across end-markets. This shift to accelerated computing is resulting in new data centre architectures requiring more efficient cooling solutions, particularly liquid cooling, as traditional air cooling alone cannot mitigate the higher heat generated as a result.

As the compute within data centres becomes higher-density, the need for effective cooling will grow, with multiple market and analyst forecasts predicting growth in liquid cooling solutions in excess of +30% CAGR in the coming years. This transaction strengthens Schneider Electric’s portfolio of direct-to-chip liquid cooling and high-capacity thermal solutions, enhancing existing offerings and furthering innovation in cooling technology.

Headquartered in Buffalo, New York, Motivair was founded in 1988 and currently has over 150 employees. Leveraging its strong engineering competency and deep domain expertise, Motivair has a range of offers including Coolant Distribution Units (CDUs), Rear Door Heat Exchangers (RDHx), Cold Plates and Heat Dissipation Units (HDUs), alongside Chillers for thermal management. Motivair provides its customers with a portfolio to meet the thermal challenges of modern computing technology.

While liquid cooling is not a new technology, specific application to the data centre and AI environment represents a nascent market set for strong growth in the coming years. Motivair has years of experience in cooling the world’s fastest supercomputers with liquid cooling solutions. In recent quarters, the company has been tracking a strong double-digit growth trajectory, which is expected to continue as it pivots to provide end-to-end liquid cooling solutions to several of the largest data centre and AI customers.

Peter Herweck, CEO of Schneider Electric, comments, “The acquisition of Motivair represents an important step, furthering our world leading position across the data centre value chain. The unique liquid cooling portfolio of Motivair complements our value proposition in data centre cooling and further strengthens our prominent position in data centre build out, from grid to chip and from chip to chiller.”

Rich Whitmore, President & CEO of Motivair Corporation - who will continue to run the Motivair business out of Buffalo after the closing of the transaction - adds, “Schneider Electric shares our core values and commitment to innovation, sustainability and excellence. Joining forces with Schneider will enable us to further scale our operations and invest in new technologies that will drive our mission forward and solidify our position as an industry leader. We are thrilled to embark on this exciting journey together."

Under the terms of the transaction, Schneider Electric will acquire an initial 75% controlling interest in the equity of Motivair for an all-cash consideration of $850 million (£652m), which includes the value of a tax step-up, and values Motivair at a mid-single digit multiple of projected FY2025 revenue.

The transaction is subject to customary closing conditions, including the receipt of required regulatory approvals, and is expected to close in the coming quarters. On completion, Motivair would be reported within the Energy Management business of Schneider Electric. The Group expects to acquire the remaining 25% of non-controlling interests in 2028.

For more from Schneider Electric, click here.

Simon Rowley - 18 October 2024

Cooling

Data Centres

News

STULZ launches new version of CyberAir Mini CW

STULZ, the mission critical air conditioning specialist, has added a standard version of the CyberAir Mini CW precision server room air conditioning unit to its range of industry leading solutions.

In response to increasing demand for quickly available cooling systems for small to medium-sized data centres, the standard version is available with a delivery time of just 14 days, offering customers decisive advantages in terms of delivery time and costs, without compromising on quality and range of potential applications.

The standard CyberAir Mini CW is a compact and efficient precision air conditioning system which is available in four sizes with capacities from 9 to 35kW. It will deliver effective climate control in server rooms and telecommunication closets, and can be easily integrated into existing building management systems (BMS). Chilled water (CW) cooling technology ensures energy efficient temperature management and it is engineered for continuous 24/7 operation.

An ideal solution for businesses looking to protect sensitive IT infrastructure with precise temperature control and low operating costs, the CyberAir Mini’s compact design allows for flexible installation in confined spaces, while the use of modular components offers scalability to meet growing cooling needs and adaptation to individual requirements. Customers can order additional accessories such as bases, blinds or humidifiers directly from STULZ, which are then delivered ready to be mounted on-site by a technician.

All the proven mechanical, thermodynamic and electrical features and benefits of the established CyberAir Mini CW series have been retained in the new standard variant, ensuring that it maintains ideal climate conditions that extend equipment life and reduce downtime. Outstanding energy efficiency is enabled thanks to electronically commutated (EC) fans that are capable of operating at partial loads, with low noise and ease of maintenance. STULZ hasn’t forgotten the importance of user friendliness and its advanced E² control system with a touchscreen display enables intuitive operation and quick parameterisation.

“The new standard version of the pioneering CyberAir Mini CW demonstrates our ongoing commitment to providing customers with air conditioning solutions that combine modern design and advanced technology with ease of use, energy efficiency, scalability and reliability,” says Emily Kay, product manager at STULZ. “We are now able to offer a particularly economical solution with extremely short delivery times and interested customers, planners and refrigeration contractors can contact their STULZ account manager at any time for further information and individual advice.”

Fore more from STULZ, click here.

Carly Weller - 16 October 2024

Cooling

Data Centres

News

Product

Vertiv introduces new cooling chillers for data centres

Vertiv, a global provider of critical digital infrastructure and continuity solutions, has announced the introduction of the high-capacity models of its Vertiv Liebert AFC inverter screw chiller range with low global warming potential (GWP) refrigerant.

Available in the EMEA region, the new models provide up to 2.2 MW of cooling capacity in a single frame, resulting in a smaller carbon emission footprint, requiring fewer units to be installed for capacity, and reducing installation and maintenance time and costs for data centre operators.

The newest Liebert AFC models are high-density, outdoor, free cooling chillers that reportedly provide the industry’s highest capacity in a single frame. These future-ready chillers enable hybrid operation for data centres deploying AI and HPC liquid cooling applications and are compliant with current regulatory requirements in the EU.

The chiller is an integral part of the overall Vertiv solution to simplify data centre deployment and management. By pairing the Liebert AFC chillers with chilled water solutions - such as Vertiv Liebert PCW perimeter air handler system, Vertiv Liebert XDU coolant distribution unit, Vertiv Liebert CWA thermal wall system, and Vertiv Liebert iCOM CWM smart control - operators can efficiently address the cooling needs of colocation and cloud data centre applications.

"As the demand for AI and HPC deployments grows, customers are increasingly seeking solutions that provide higher cooling capacity within a compact footprint," states George Hannah, Senior Global Director for Chilled Water Systems at Vertiv. "The latest Liebert AFC low-GWP chillers reach up to 2.2 MW, in a form factor that significantly reduces the time, cost, and complexity of deploying these systems. This solution supports Vertiv's commitment to environmental responsibility and compliance with the latest regulatory standards, and aligns with the company's objectives to continue its industry-leading expertise in air and liquid cooling applications."

Vertiv Liebert AFC offers up to 20% lower annual energy consumption compared to fixed screw solutions. The inverter-driven compressor allows for the reduction of energy consumption and, in particular, the electrical power required during peaks, which in turn allows more power availability for the IT equipment. The innovative regulation algorithms offer accurate control of the fluid delivery temperature to the indoor units, enhancing cooling continuity and reliability. The unit is designed to operate with a more eco-friendly refrigerant R1234ze HFO, which allows data centre owners to comply with the EU F-Gas Regulation 2024/573 and enables customers to support pressing sustainability goals.

For more from Vertiv, click here.

Simon Rowley - 2 October 2024

Cooling

Data Centres

News

Product

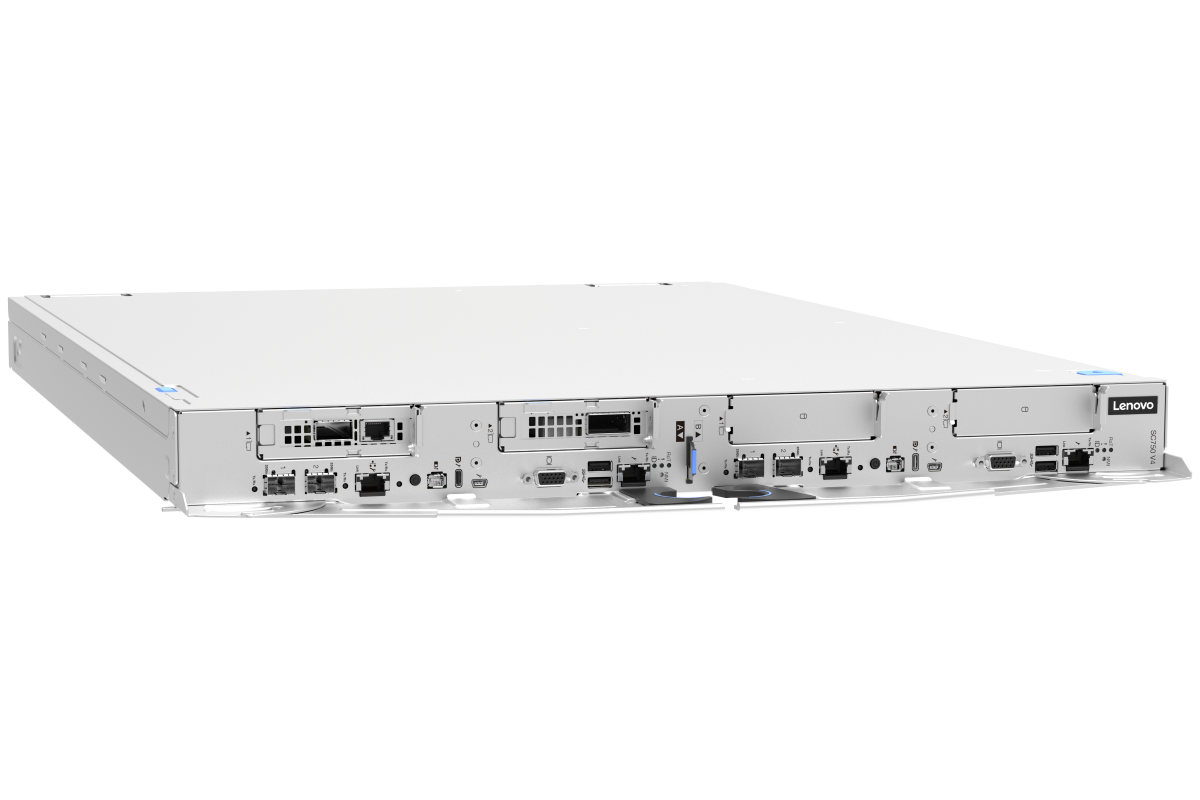

Lenovo expands Neptune liquid cooling ecosystem

Lenovo has expanded its Neptune liquid-cooling technology to more servers with new ThinkSystem V4 designs that help businesses boost intelligence, consolidate IT and lower power consumption in the new era of AI.

Powered by Intel Xeon 6 processors with P-cores, the new Lenovo ThinkSystem SC750 V4 supercomputing infrastructure (pictured above) combines peak performance with advanced efficiency to deliver faster insights in a space-optimised design for intensive HPC workloads.

The full portfolio includes new Intel-based solutions optimised for rack density and massive transactional data, maximising processing performance in the data centre space for HPC and AI workloads.

“Lenovo is helping enterprises of every size and across every industry bring new AI use cases to life based on improvements in real-time computing, power efficiency and ease of deployment,” says Scott Tease, Vice President and General Manager of High-Performance Computing and AI at Lenovo. “The new Lenovo ThinkSystem V4 solutions powered by Intel will transform business intelligence and analytics by delivering AI-level compute in a smaller footprint that consumes less energy.”As part of its ongoing investment in accelerating AI, Lenovo is pushing the envelope with the sixth generation of its Lenovo Neptune liquid-cooling technology, delivering it for mainstream use throughout its ThinkSystem V3 and V4 portfolios through compact design innovations that maximise computing performance while consuming less energy. Lenovo’s proprietary direct water-cooling recycles loops of warm water to cool data centre systems, enabling up to a 40% reduction in power consumption.The Lenovo ThinkSystem SC750 V4 helps support customers’ sustainability goals data centre operations with highly efficient direct water-cooling built directly into the solution and accelerators that deliver even greater workload efficiency with exceptional performance per watt. Engineered for space-optimised computing, the infrastructure fits within less than a square meter of data centre space in industry-standard 19-inch racks, pushing the boundaries of compact general-purpose supercomputing.

Leveraging the new infrastructure, organisations can achieve faster time-to-value by quickly and securely unlocking new insights from their data. The ThinkSystem SC750 V4 uses a next-generation MRDIMM memory solution to increase critical memory bandwidth by up to 40%. It is also designed for handling sensitive workloads with enhanced security features for greater protection.

Building on Lenovo’s leadership in AI innovation, the new solutions achieve advanced performance, increased reliability and higher density to propel intelligence.

For more from Lenovo, click here.

Simon Rowley - 26 September 2024

Cooling

Data Centres

News

Park Place Technologies introduces liquid cooling solutions

Park Place Technologies, a global data centre and networking optimisation firm, has announced the expansion of its portfolio of IT infrastructure services with the introduction of two liquid cooling solutions for data centres: immersion liquid cooling and direct-to-chip cooling.

This announcement comes at a critical time for businesses who are seeing a dramatic increase in the compute power they require, driven by adoption of technologies like AI and IoT. This, in turn, is driving the need for more on-prem hardware, more space for that hardware, and more energy to run it all – presenting a significant financial and environmental challenge for businesses. Park Place Technology says that its new liquid cooling solutions present a strong solution for businesses looking to address these challenges, as the technology has the potential to deliver strong financial and environmental results.

Direct-to-chip is an advanced cooling method that applies coolant directly to the server components that generate the most heat including CPUs and GPUs. Immersion cooling empowers data centre operators to do more with less: less space and less energy. Using these methods, businesses can increase their Power Usage Effectiveness (PUE) by up to 18 times, and rack density by up to 10 times. Ultimately, this can help deliver power savings of up to 50%, which in turn leads to lower operation costs.

From an environmental perspective, liquid cooling is significantly more efficient than traditional air cooling. At present, air cooling technology only captures 30% of the heat generated by the servers, compared to the 100% captured by immersion cooling, resulting in lower carbon emissions for businesses that opt for immersion cooling methods.

Park Place Technologies can deliver a complete turnkey solution for organisations looking to implement liquid cooling technology, removing the complexity of adoption, which is a common barrier for businesses. Park Place Technologies provides a single-vendor solution for the whole process from procuring the hardware, conversion of the servers for liquid cooling, installation, maintenance, monitoring and management of the hardware and the cooling technology.

“Our new liquid cooling offerings have the potential to have a significant impact on our customers’ costs and carbon emissions, two of the key issues they face today,” says Chris Carreiro, Chief Technology Officer at Park Place Technologies. “Park Place Technologies is ideally positioned to help organisations cut their data centre operations costs, giving them the opportunity to re-invest in driving innovation across their businesses.

“The decision to invest in immersion cooling and direct-to-chip cooling depends on various factors, including the specific requirements of the data centre, budget constraints, the desired level of cooling efficiency, and infrastructure complexity. Park Place Technologies can work closely with customers to find the best solution for their business, and can guide them towards the best long-term strategy, while offering short-term results. This takes much of the complexity out of the process, which will enable more businesses to capitalise on this exciting new technology.”

Simon Rowley - 24 September 2024

Colocation

Cooling

Data Centres

News

STT GDC and Phaidra to optimise data centre cooling with AI

ST Telemedia Global Data Centres (STT GDC), one of the world’s fastest-growing data centre colocation services providers, today announced its collaboration with Phaidra, a pioneer of using artificial intelligence (AI) to improve efficiency, stability, and sustainability, to pilot an AI-based autonomous control system for optimising data centre cooling in STT GDC’s facilities in Singapore.

Phaidra provides AI-powered control systems for data centres. Its autonomous AI agents build upon legacy control systems and support facility operations teams by analysing thousands of sensor trends in real-time to maximise energy efficiency, reliability, and cooling performance using specialised deep learning models.

Because this is a closed-loop solution, these AI agents continuously learn and adapt to changing facility conditions, such as load variations, due to higher density GPU deployments or external weather changes.

STT GDC’s commitment to be carbon neutral by 2030, along with its collaboration with Phaidra, aligns with Singapore’s vision of a greener future for the data centre industry. As the power needs of AI workloads continue to grow, data centre cooling and operational infrastructure must evolve to keep pace. This evolution is essential to more effectively and sustainably manage the heat generated by the high-performance computing requirements necessary to support accelerated computing workloads such as AI and beyond.

STT GDC will be the first operator to pilot Phaidra’s AI-powered control systems in Asia, setting a unique precedent by testing them in a hybrid cooling environment that is technically more challenging as compared to traditional air-cooled data centres. Selected STT GDC data centres offer a combination of both air-cooling and liquid-cooling solutions, supporting diverse computing workloads within the same facility. This pioneering effort underscores STT GDC’s commitment to innovative and sustainable data centre management. Based on existing site parameters, an initial estimate of 10% in cooling energy savings is anticipated. As the AI model is fed more operational data, energy savings are expected to increase from the 10% baseline to as high as 30%. This flagship pilot will serve as a model for possible subsequent deployments across STT GDC’s portfolio of data centres globally.

Daniel Pointon, Group Chief Technology Officer, ST Telemedia Global Data Centres, comments, “Combining our expertise in delivering AI-ready data centres across major economic hubs with Phaidra’s industry-leading know-how in using AI to optimise mission-critical control systems, we are leading the way in using AI to further drive sustainability within our data centres. Through this collaboration, we are not only seeing meaningful impact on our ongoing decarbonisation efforts, but also significant efficiency gains in data centre operations that already offer a hybrid of both air and liquid cooling. This pilot is testament to our commitment to drive sustainable innovation across our data centres.”

Jim Gao, CEO and Co-Founder of Phaidra, adds, “Phaidra is proud to work with a leading data centre services provider like STT GDC. Its culture of operational excellence, relentless improvement and innovation makes for a natural partnership. We look forward to driving the data centre industry forward together.”

AI is already making inroads towards transforming the global economy. Analysis from PWC indicates that AI could potentially contribute up to $15.7 trillion to the global economy by 2030, along with up to 26% boost in GDP for local economies from AI by the same year. While a sufficient level of AI-readiness is required to take advantage of these economic opportunities, there also must be considerations towards doing so in a sustainable manner.

As a leading data centre hub both regionally and internationally, Singapore is uniquely positioned to drive sustainable innovation in the data centre space. Recently, Singapore announced its Green Data Centre Roadmap for sustainable growth, with plans to accelerate data centres’ energy efficiency at both hardware and software levels, as well as to increase data centres’ use of green energy to expand capacity.

For more from STT GDC, click here.

Simon Rowley - 27 August 2024

Cooling

Data Centres

News

BAC unveils Loop Platform for enhanced cooling

Baltimore Aircoil Company (BAC), a global provider of cooling equipment, has announced the launch of its innovative AI-driven Loop Platform.

BAC claims that the platform, which is designed to enhance the efficiency and performance of HVAC systems, marks a significant advancement in cooling systems management.

Loop is an advanced AI platform that seamlessly integrates with existing cooling tower systems. This compact yet powerful device is engineered to optimise operational efficiency by continuously monitoring and adjusting for environmental conditions. Its AI algorithms analyse data in real-time, ensure optimal performance and enable predictive maintenance. The result is significant energy savings, reduced maintenance costs, and extended equipment lifespan.

This platform is tailored for end users, including building and facility owners, managers, and maintenance professionals. The Loop Platform is designed to operate as an easy-to-use solution that not only improves system reliability, but also contributes to sustainability goals by reducing energy consumption. Maintenance professionals will appreciate the platform's ability to predict potential issues before they escalate, streamlining maintenance schedules and minimising unexpected downtime.

"BAC is excited to introduce the Loop Platform, a product that embodies our commitment to innovation and sustainability," says Adam Bee, Vice President of Business Development at Baltimore Aircoil Company. "We understand the challenges faced by building owners and facility managers in maintaining efficient cooling systems. Loop offers a smart, user-friendly solution that simplifies these tasks while delivering measurable savings."

For more from BAC, click here.

Simon Rowley - 22 August 2024

Head office & Accounts:

Suite 14, 6-8 Revenge Road, Lordswood

Kent ME5 8UD

T: +44 (0)1634 673163

F: +44 (0)1634 673173